High-density three-dimensional stacking and assembling method for electronic modules

A three-dimensional stacking, electronic module technology, applied in the computer field, to improve the integration density and solve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

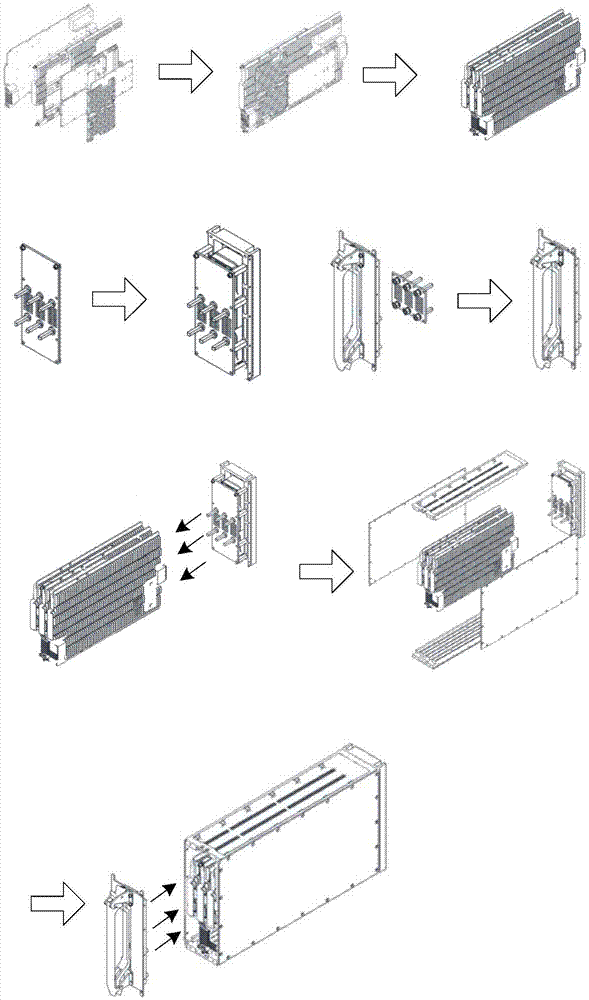

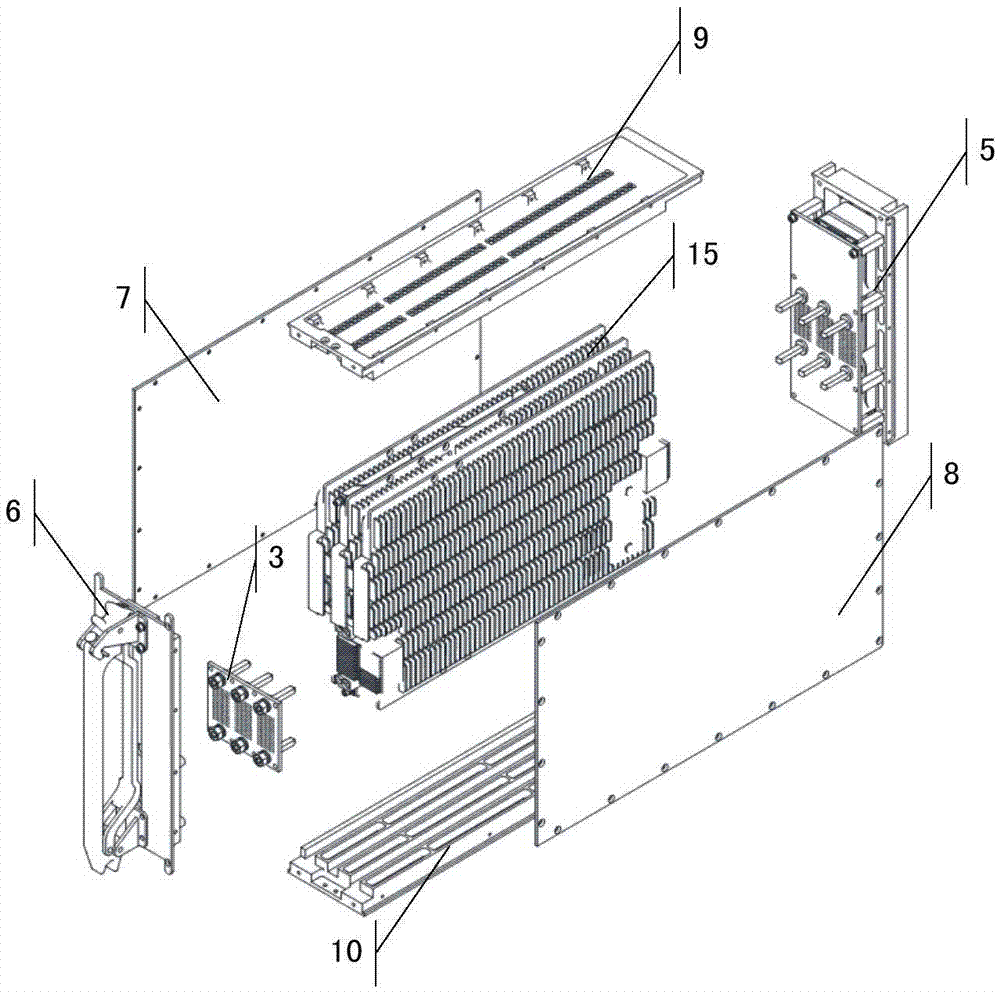

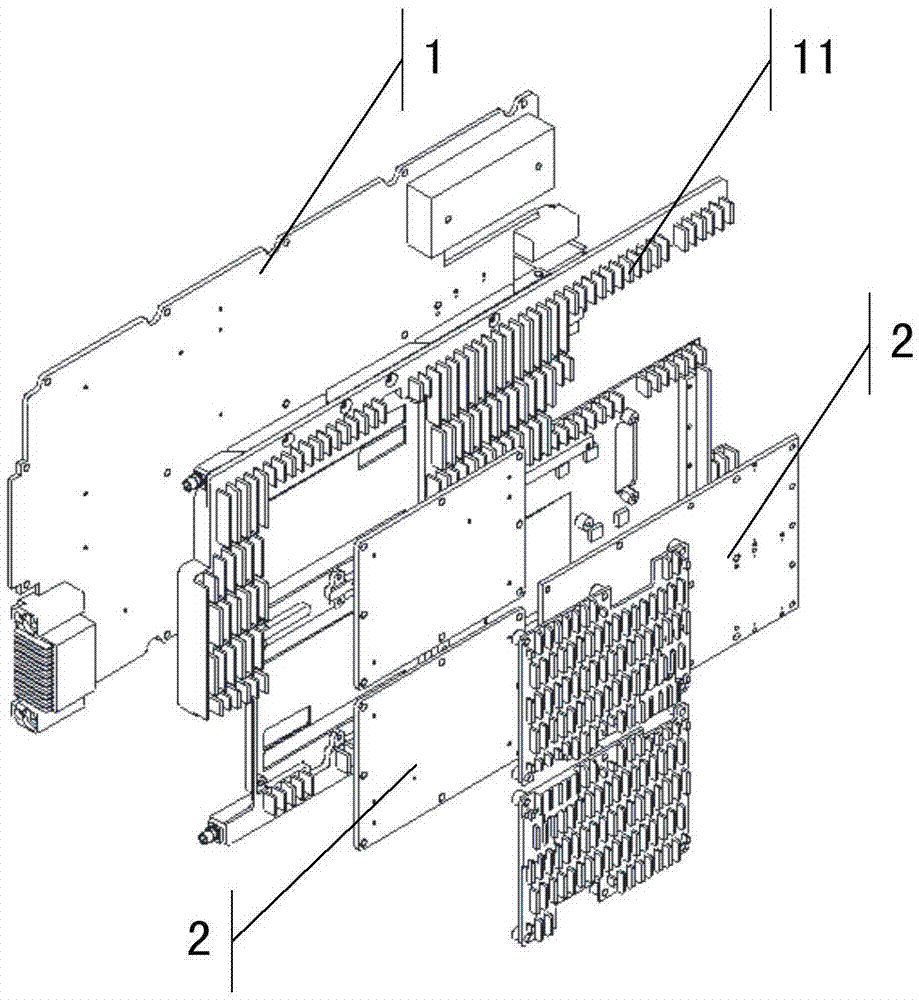

[0033] A high-density three-dimensional stacking and assembling method for electronic modules, which consists of multiple functional circuit boards, functional circuit sub-cards, front motherboards, rear motherboards and other circuit components, as well as the rear cover of the chassis, the front cover of the chassis, the left cover of the chassis, The structural components such as the right cover plate of the chassis, the upper frame of the chassis, and the lower frame of the chassis are stacked through multi-dimensional and multi-level methods, such as figure 1 shown.

[0034] The specific stacking and assembly steps are as follows: figure 2 Shown:

[0035] 1] Through the inter-board parallel connector, perform parallel stacking of functional circuit boards, functional circuit sub-cards and heat dissipation plates to complete functional circuit components, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com