Automobile wire harness

A technology of automotive wiring harnesses and wiring harnesses, which is applied in the direction of electrical components, bases/housings, coupling devices, etc., can solve the problems of affecting the transmission stability of wiring harnesses, the confusion of cables at the connection end, and the low concentration between wires, so as to achieve clear line distribution and easy Low maintenance and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] like figure 1 As shown, the automobile wiring harness of the present invention includes:

[0028] first harness 1, as in figure 2 As shown, the first wire harness 1 is provided with a number of first wires 101, the first end of the first wire harness 1 is sleeved with a first number tube 102, and the second end of the first wire harness 1 is sleeved A second number tube 103 is connected, and several first wires 101 are fixed by first cable ties 104 . Both the first number tube 102 and the second number tube 103 are white cylindrical sleeves. The heat-shrinkable sleeve 3 is a black cylindrical sleeve.

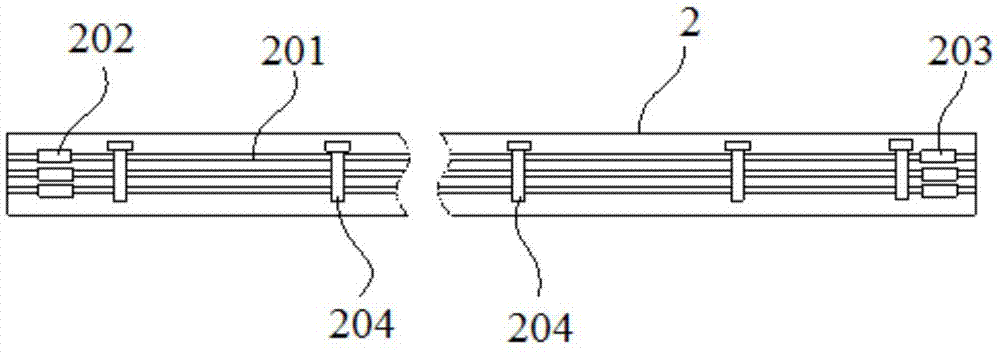

[0029] The second harness 2, such as image 3 As shown, the second wire harness 2 is provided with a number of second wires 201, the first end of the second wire harness 2 is externally sleeved with a third number tube 202, and the second end of the second wire harness 2 is externally sleeved A fourth number pipe 203 is connected, and several second wires 201 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com