A kind of manufacturing method of positive electrode of lithium-sulfur battery

A production method and technology for lithium-sulfur batteries, which are applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as small proportion, poor shelving performance, and practical obstacles to sulfur dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

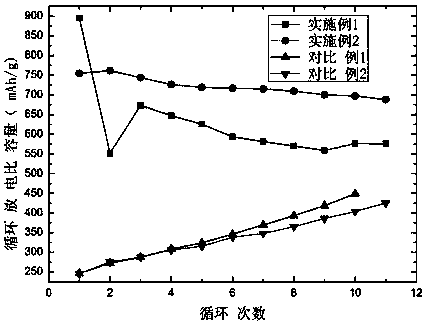

Embodiment 1

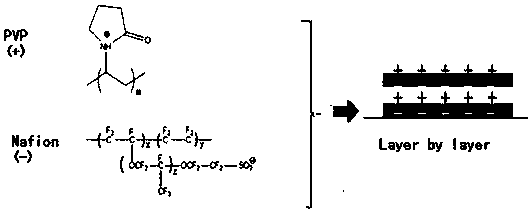

[0024] Slurry A: Weigh the carbon-sulfur compound (sulfur content 70%), conductive agent KB600 and binder PVP according to the ratio of 70:10:20, first put the weighed carbon-sulfur compound and conductive agent into the dispersion Add isopropanol (according to the amount of isopropanol weighed according to the solid content of the slurry at 3%), sonicate for 120 minutes to disperse and mix the two evenly; then add PVP (molecular weight ~ 50W), and continue to sonicate for 30 minutes.

[0025] Slurry B: Weigh the carbon-sulfur compound (sulfur content 70%), conductive agent KB600 and binder Nafion according to the ratio of 70:10:20, first put the weighed carbon-sulfur compound and conductive agent into the dispersion Add isopropanol (according to the amount of isopropanol weighed according to the solid content of the slurry at 3%), sonicate for 120 minutes to disperse and mix the two evenly; then add Nafion (EW1100), and continue to sonicate for 30 minutes. (Wherein, EW refers...

Embodiment 2

[0028] Slurry A: Weigh the carbon-sulfur compound (sulfur content 70%), conductive agent KB600 and binder PVP according to the ratio of 80:10:10, first put the weighed carbon-sulfur compound and conductive agent into the dispersion Add isopropanol (according to the amount of isopropanol weighed according to the solid content of the slurry at 3%), sonicate for 120 minutes to disperse and mix the two evenly; then add PVP (molecular weight ~ 50W), and continue to sonicate for 30 minutes.

[0029] Slurry B: Weigh the carbon-sulfur compound (sulfur content 70%), conductive agent KB600 and binder Nafion according to the ratio of 80:10:10, first put the weighed carbon-sulfur compound and conductive agent into the dispersion Add isopropanol (according to the amount of isopropanol weighed according to the solid content of the slurry at 3%), sonicate for 120 minutes to disperse and mix the two evenly; then add Nafion (EW1100), and continue to sonicate for 30 minutes.

[0030] The above ...

Embodiment 3

[0032] Slurry A: Weigh the carbon-sulfur compound (sulfur content 70%), conductive agent KB600 and binder PVP according to the ratio of 70:10:20, first put the weighed carbon-sulfur compound and conductive agent into the dispersion Add isopropanol (according to the amount of isopropanol weighed according to the solid content of the slurry at 3%), sonicate for 120 minutes to disperse and mix the two evenly; then add chitosan oligosaccharide (molecular weight ~ 50W), and continue to sonicate for 30 minutes.

[0033] Slurry B: Weigh the carbon-sulfur compound (sulfur content 70%), conductive agent KB600 and binder Nafion according to the ratio of 70:10:20, first put the weighed carbon-sulfur compound and conductive agent into the dispersion In the isopropanol (according to the amount of isopropanol weighed according to the solid content of the slurry at 3%), ultrasonic for 120min to disperse and mix the two evenly; then add sulfonated polyether ether ketone (sulfonated degree 80%)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com