An installation support track for an underwater vehicle battery pack

A technology for underwater vehicles and battery packs, which is applied to battery pack components, batteries, circuits, etc., and can solve the scratches on the shell of the battery pack and the inner wall of the shell of the underwater vehicle, and the running resistance of the battery pack into and out of the shell Large, underwater vehicle shell inner wall contact and other problems, to achieve the effect of good rolling friction characteristics, light weight, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

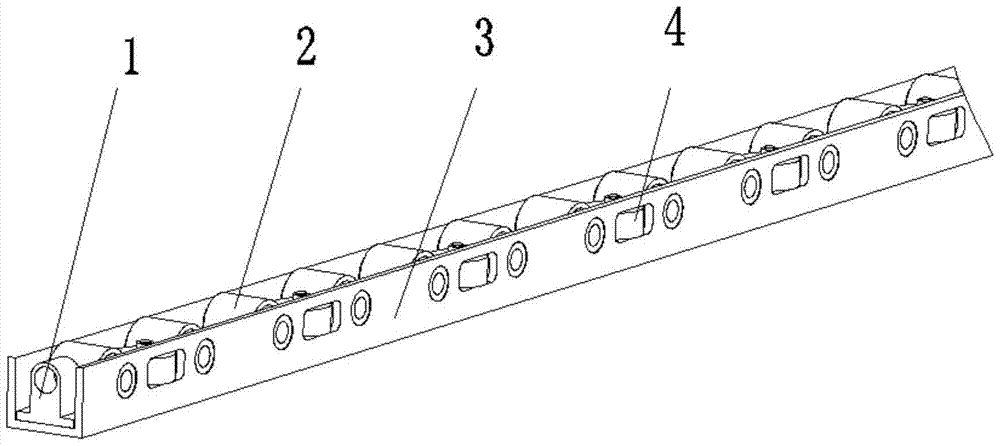

[0027] The invention provides an installation support rail for an underwater vehicle battery pack, see attached figure 1 , including: positioning hole seat 1, support wheel 2, installation base 3, guide wheel 4 and bushing 19;

[0028] See attached figure 2 , the installation base 3 is a U-shaped strip structure, and evenly distributed square holes and round holes are respectively opened on the two side plates of the U-shaped strip structure; the material of the installation base 3 is selected from high-strength aluminum profiles , its high-strength characteristics enable the entire track to maintain good rigidity in a state of light weight and small size, and due to the serialization and standardization of aluminum profiles, the track has the advantages of simple structure, low cost, and good processing technology;

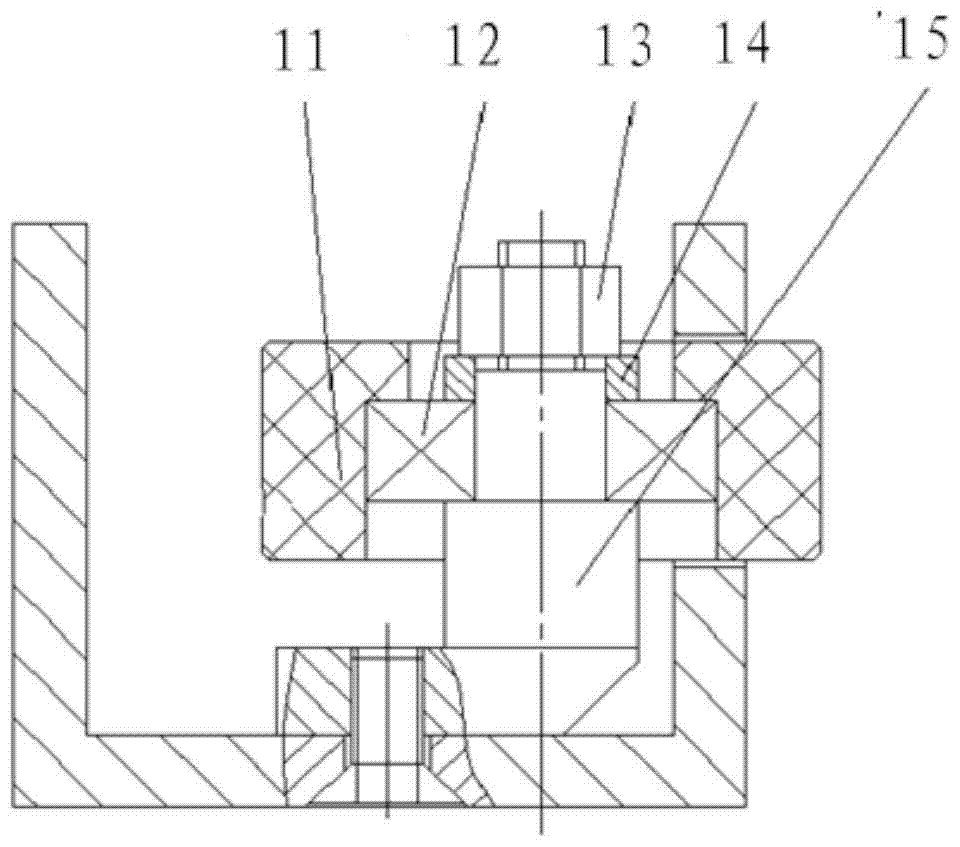

[0029] See attached image 3 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com