Miniature electromagnetic relay

An electromagnetic relay, a small technology, applied in electromagnetic relays, electromagnetic relay details, relays and other directions, can solve the problems of high reliability, low cost, high withstand voltage requirements, to expand the use market, good isolation, increase creepage effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

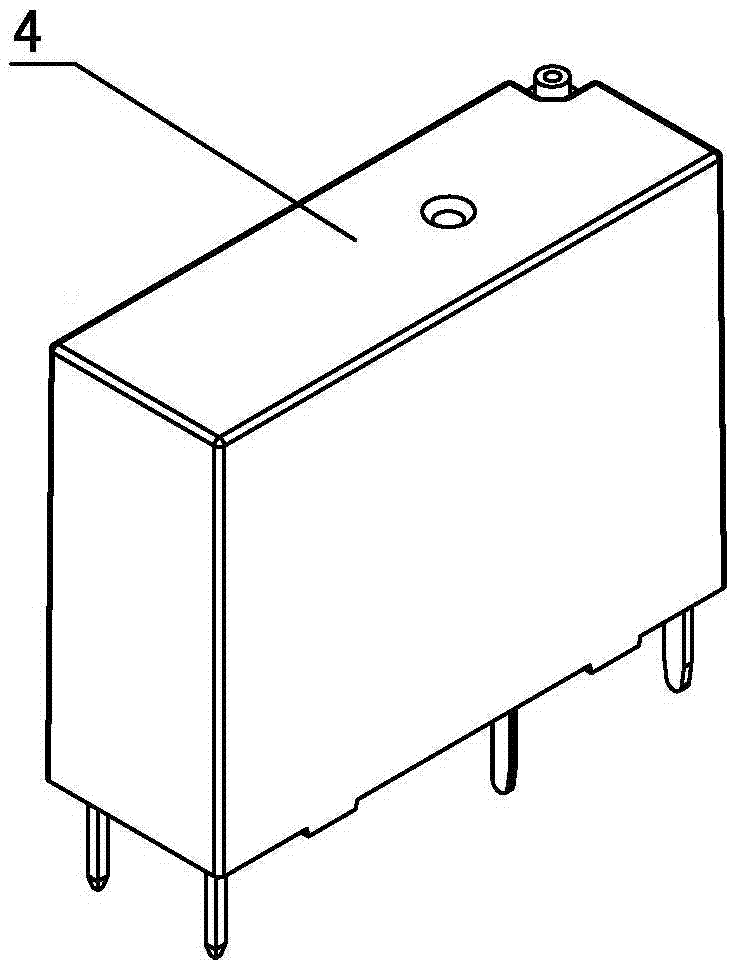

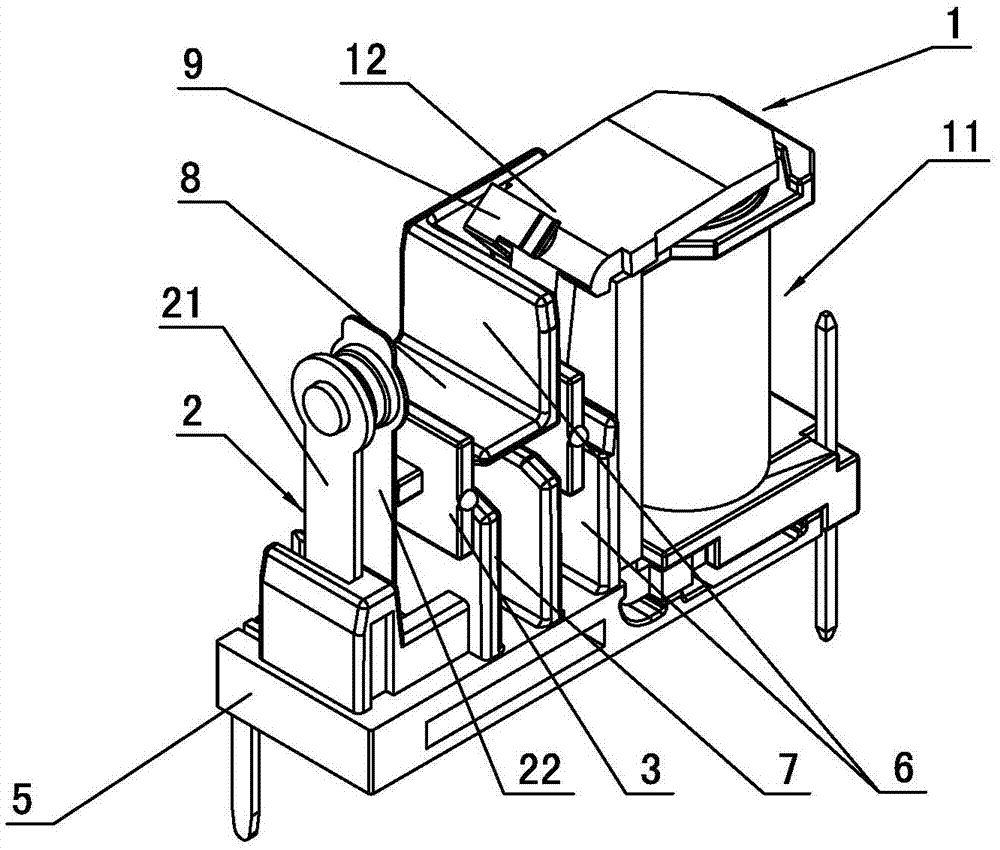

[0031]As shown in the figure, a small electromagnetic relay includes a magnetic circuit system 1, a contact system 2, a push block 3, a cover 4, and a base 5. The magnetic circuit system 1 includes an electromagnetic system 11 and an armature 12. The electromagnetic system 11 includes an iron Core 111, yoke 112, contact system 2 includes static contact group 21 and dynamic contact group 22, base 5 includes relay magnetic circuit system installation part 51, contact system installation part 52, electromagnetic system 11 and contact system 2 are arranged There is a first partition wall 6, and the first partition wall 6 is provided with a first push block chute 62 for installing the push block 3, and one end of the first partition wall 6 is integrally provided with an isolation bend extending toward the magnetic circuit system installation part 51. The folding part 61, the notch of the first pushing block slide groove 62 is arranged on the other end of the first partition wall 6, ...

Embodiment 2

[0034] The technical features are the same as those of the first embodiment, except that the second rib 42 is not integrally provided on the top wall of the casing 4 .

[0035] In the above embodiment, on the relay assembly line, when the parts and components of the relay are assembled with the base 5, Such as Figure 13 As shown, under the condition that the primary positioning of the base 5 remains unchanged, the pushing block 3, the dynamic contact group 22, the static contact group 21, the electromagnetic system 11, and the armature 12 are installed in the base 5 in sequence on the same axial direction. , simplifies the assembly on the production line of the relay, it is very convenient to operate, and it is easy to realize the automatic production of the relay, which greatly improves the efficiency of the production of the relay; The technical performance parameters of the assembled electromagnetic relay can be well controlled, so that the pass-through rate of the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com