Light and thin toughened glass 3D polarized eyeglass

A technology of tempered glass and polarized lenses, which is applied in the field of optical lenses, can solve the problems of complex preparation process and high cost, and achieve the effect of light and thin lenses, avoiding wear and tear, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described below with reference to the accompanying drawings. Those skilled in the art should understand that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention. Many changes can be made in the specific embodiments which are disclosed and still obtain a like or similar result without departing from the spirit and scope of the invention.

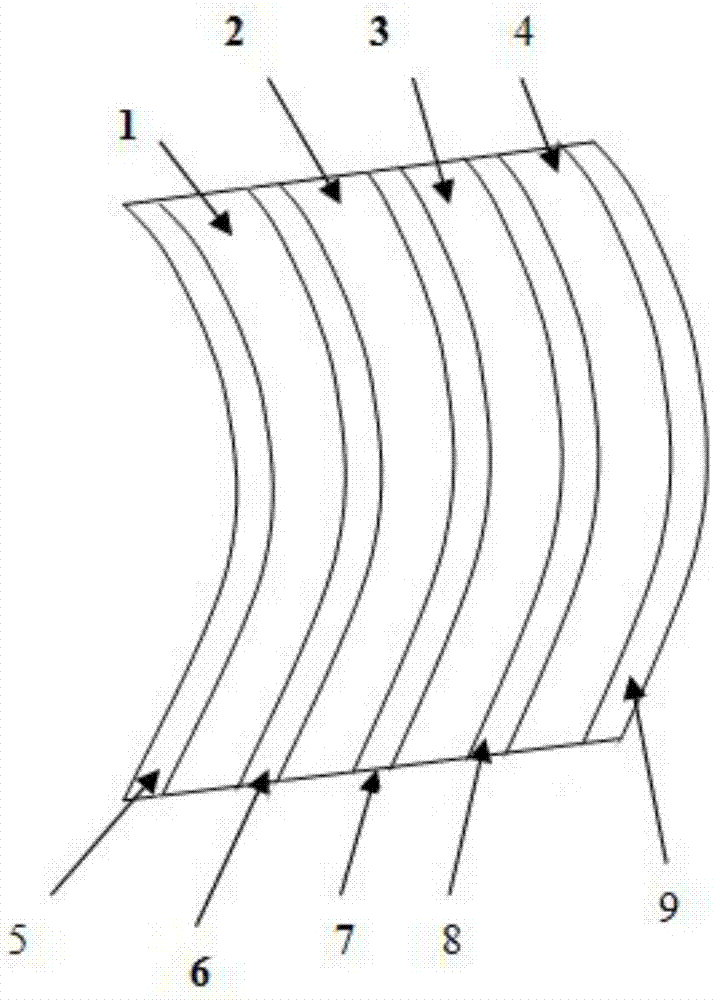

[0019] A light and thin tempered glass 3D polarizing lens, characterized in that it includes a first coating layer 5, a second coating layer 9, a first glue layer 6, a second glue layer 7, a third glue layer 8, A flake layers 4, B Sheet layer 1, 3D film layer 2 and polarizing film layer 3, the convex surface of the first coating layer 5 is connected to the concave surface of the B sheet layer 1, and the convex surface of the B sheet layer 1 is connected to the concave surface of the first glue layer 6. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com