Blue-light-proof film

A technology of anti-blue light and blue light absorption, applied in optics, optical components, instruments, etc., can solve the problem of less attention on computer film, and achieve the effect of improving the effect of absorbing blue light and filtering blue light well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

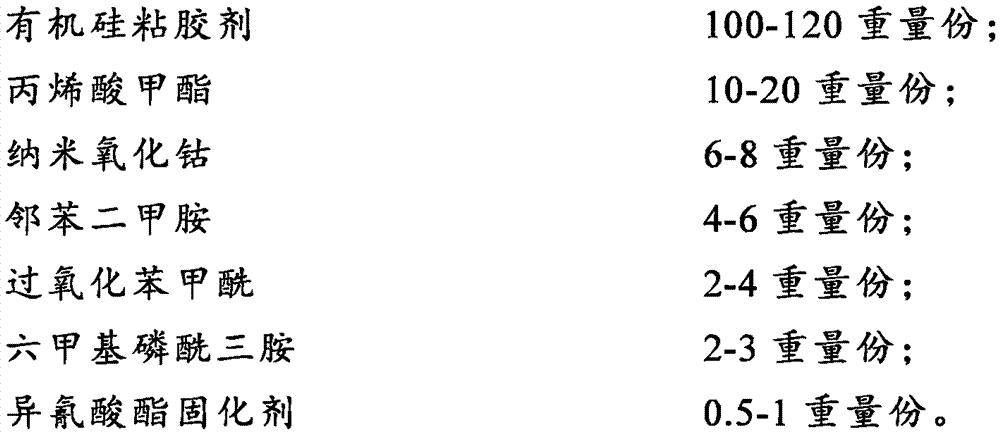

[0062] The raw material formula of the release protective film is as follows:

[0063]

[0064] The preparation process of release protective film comprises the following steps:

[0065] 1. Carry out corresponding parts by weight of trifluoropropylmethylcyclotrisiloxane, polytrimethylene terephthalate, hydroxyethyl cellulose, nano silicon dioxide, methacryloxypropyltrimethoxysilane Mix and mix thoroughly with a mixer;

[0066] 2. In step (1), add vinyl silicone oil, dioctyl adipate, and antioxidant, stir at 500-1000 rpm, and heat to 120-160°C at the same time to obtain a coating material;

[0067] 3. Co-extrude the coating material on the PET paper through the coating agent film head, the co-extrusion temperature is 230-280 ℃, the back pressure is 600pa-1000pa, and the co-extrusion speed is 100-150m / min.

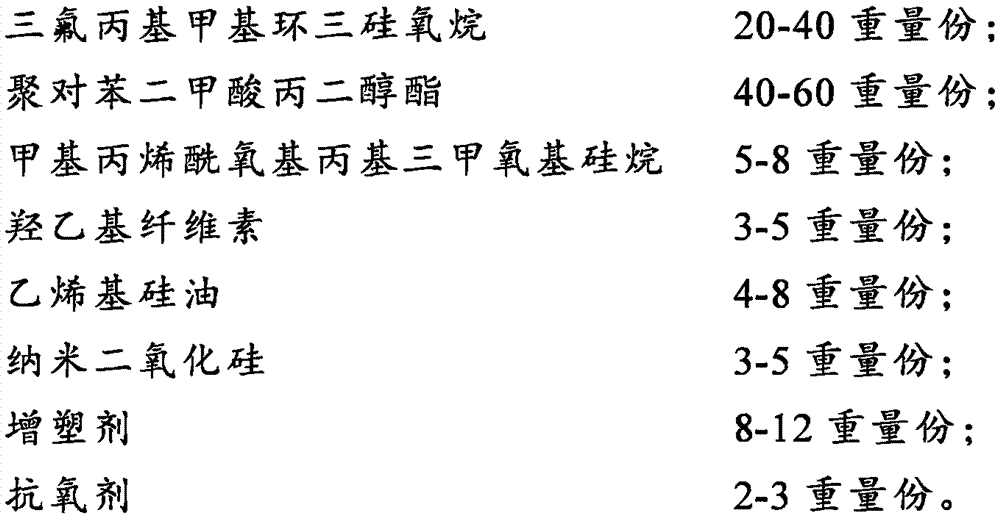

[0068] The raw material formula of the anti-blue light adhesive layer includes the following materials by weight:

[0069]

[0070] The anti-blue light adhesive lay...

Embodiment 2

[0084] The raw material formula of the release protective film is as follows:

[0085]

[0086] The preparation process of release protective film comprises the following steps:

[0087] 1. Carry out corresponding parts by weight of trifluoropropylmethylcyclotrisiloxane, polytrimethylene terephthalate, hydroxyethyl cellulose, methacryloxypropyltrimethoxysilane, and nano silicon dioxide Mix and mix thoroughly with a mixer;

[0088] 2. In step (1), add vinyl silicone oil, dioctyl adipate, and antioxidant 1010, stir at 500-1000 rpm, and heat to 120-160°C at the same time to obtain a coating material;

[0089] 3. Co-extrude the coating material on the PET paper through the coating agent film head, the co-extrusion temperature is 230-280 ℃, the back pressure is 600pa-1000pa, and the co-extrusion speed is 100-150m / min.

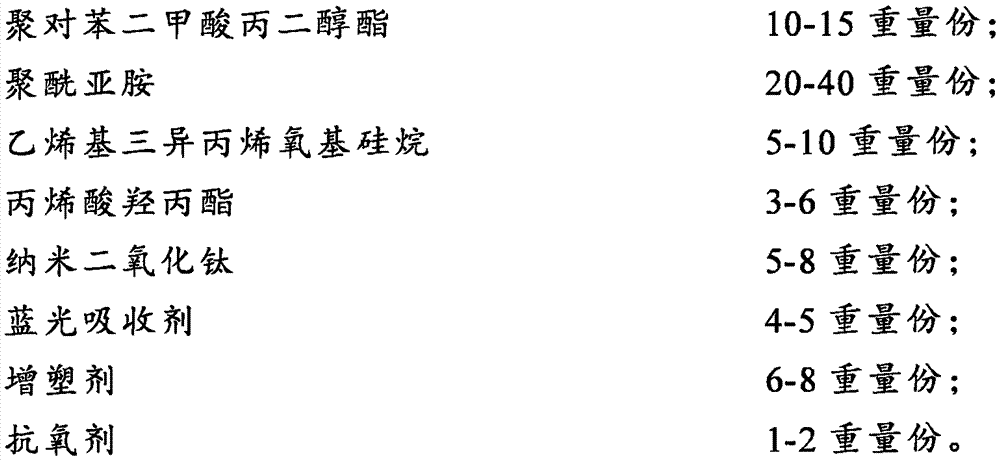

[0090] The raw material formula of the anti-blue light adhesive layer is as follows:

[0091]

[0092]

[0093] The anti-blue light adhesive layer is pr...

Embodiment 3

[0107] The raw material formula of the release protective film is as follows:

[0108]

[0109] The preparation process of release protective film comprises the following steps:

[0110] 1. Carry out corresponding parts by weight of trifluoropropylmethylcyclotrisiloxane, polytrimethylene terephthalate, hydroxyethyl cellulose, methacryloxypropyltrimethoxysilane, and nano silicon dioxide Mix and mix thoroughly with a mixer;

[0111] 2. In step (1), add vinyl silicone oil, dioctyl adipate, and antioxidant 1010, stir at 500-1000 rpm, and heat to 120-160°C at the same time to obtain a coating material;

[0112] 3. Co-extrude the coating material on the PET paper through the coating agent film head, the co-extrusion temperature is 230-280 ℃, the back pressure is 600pa-1000pa, and the co-extrusion speed is 100-150m / min.

[0113] The raw material formula of the anti-blue light adhesive layer is as follows:

[0114]

[0115] The anti-blue light adhesive layer is prepared accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com