Dual-rotation worm drive device capable of automatically filtering and cleaning bituminous coal firing products

A kind of bituminous coal burning material and automatic filtration technology, which is applied in the direction of filtration separation, gravity filter, fixed filter element filter, etc., can solve the problems of high labor intensity, achieve the goal of reducing labor intensity, compact structure, and improving solution filtration efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

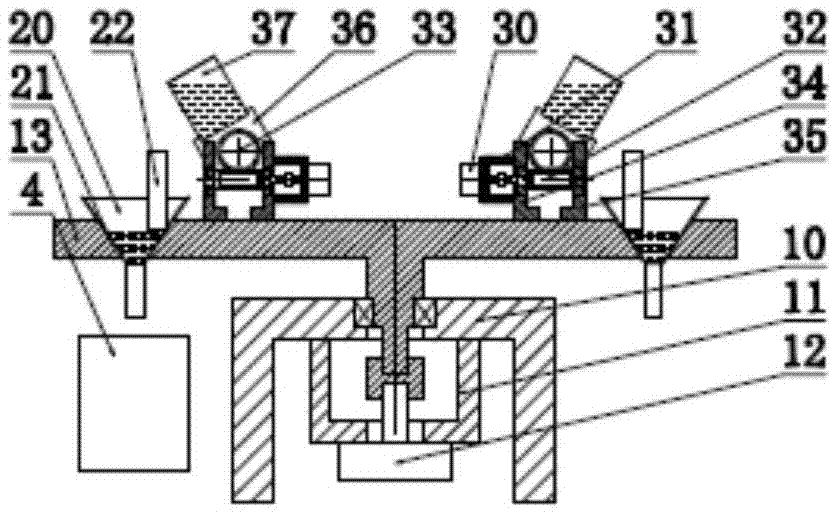

[0017] see figure 1 As shown, a dual-rotation worm transmission device for automatic filtering and cleaning of bituminous coal burnt matter of the present invention includes a waste liquid bucket 4, a dual-rotation module, four beaker worm gear tilting modules and four solution filtration modules.

[0018] see figure 1 As shown, the double rotation module includes a frame 10 , a motor frame 11 , a rotating motor 12 and a rotating disk 13 .

[0019] see figure 1 As shown, the motor frame 11 is installed on the frame 10, on which a rotating motor 12 is installed; the output shaft of the rotating motor 12 is connected with the lower end of the rotating disk 13, and the rotating motor 12 rotates to drive the rotating disk 13 to rotate.

[0020] see figure 1 As shown, the four beaker worm gear tilting modules are respectively installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com