Double-translational-motion direct connection equipment for automatically filtering and cleaning bituminous coal burning matter

A bituminous coal burning material and automatic filtering technology, which is applied in the preparation of test samples and other directions, can solve the problems of high labor intensity, and achieve the effects of good movement stability, reasonable structure, and reduction of labor intensity and manual participation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

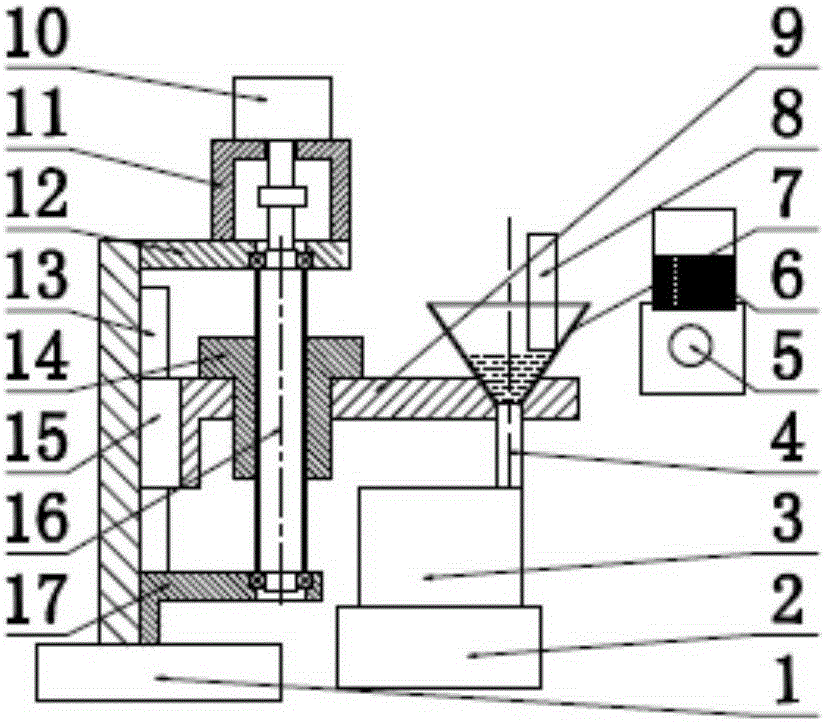

[0016] see figure 1 As shown, a double-translation direct-connection device for automatic filtering and cleaning of bituminous coal burnt matter of the present invention includes a forward translation module 1, a reverse translation module 2, and a funnel lifting module installed on the forward translation module 1. The tilting module 5, the first beaker 6 installed on the tilting module 5, the funnel 4, the filter paper 7 installed on the inner surface of the funnel 4, the glass rod 8 installed on the filter paper 7, installed in the reverse translation module 2 N second beakers 3 arranged in a straight line along the Y-axis in the horizontal plane.

[0017] see figure 1 As shown, both the forward translation module 1 and the reverse translation module 2 can realize linear motion in the Y-axis direction.

[0018] see figure 1 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com