Jacking mechanism and trolley using same

A technology of jacking mechanism and trolley, which is applied in the direction of shaft lining, tunnel lining, underground chamber, etc., can solve the problems of restricting the popularization of use, increasing the labor intensity of operators, and greatly affecting the construction quality, so as to increase the smoothness and Rapidity, simple, convenient and fast conversion, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

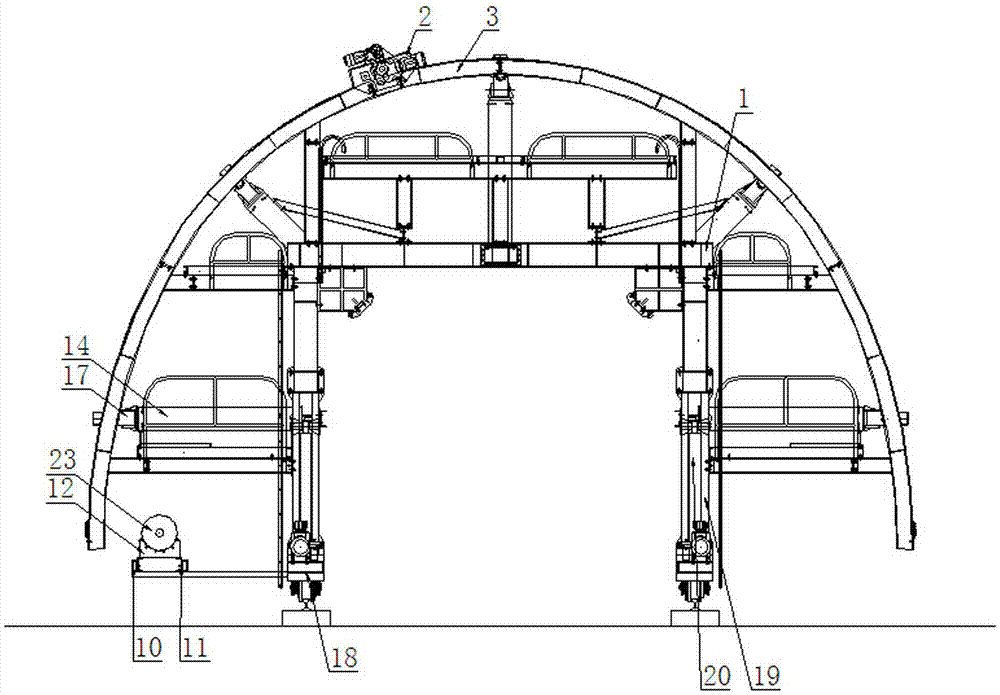

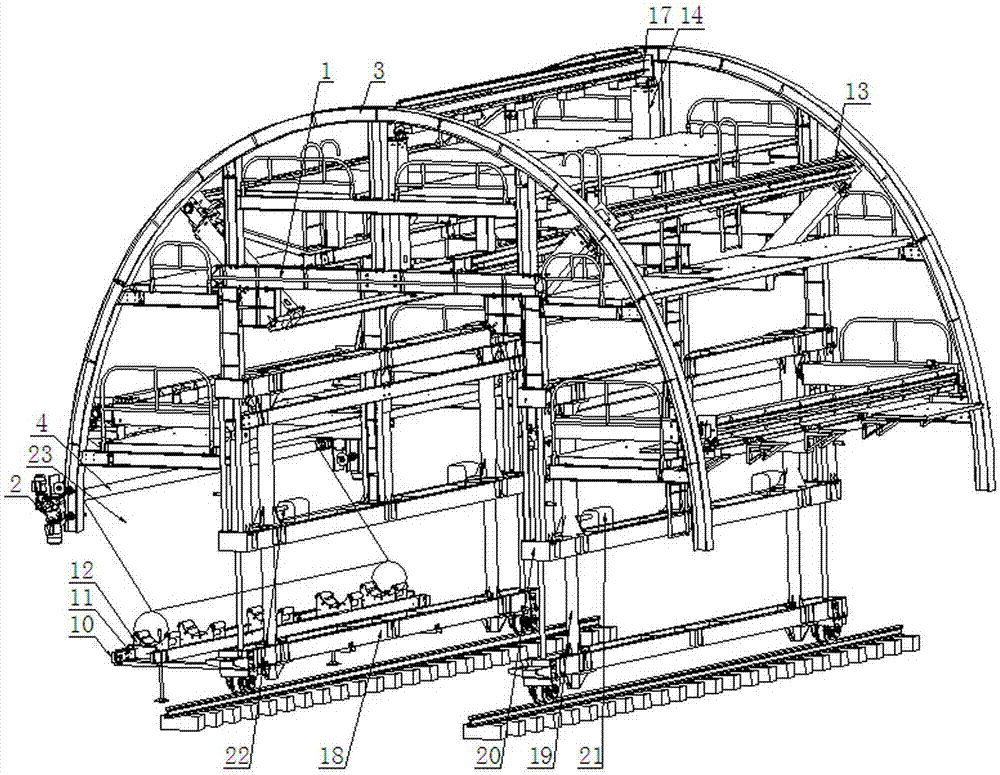

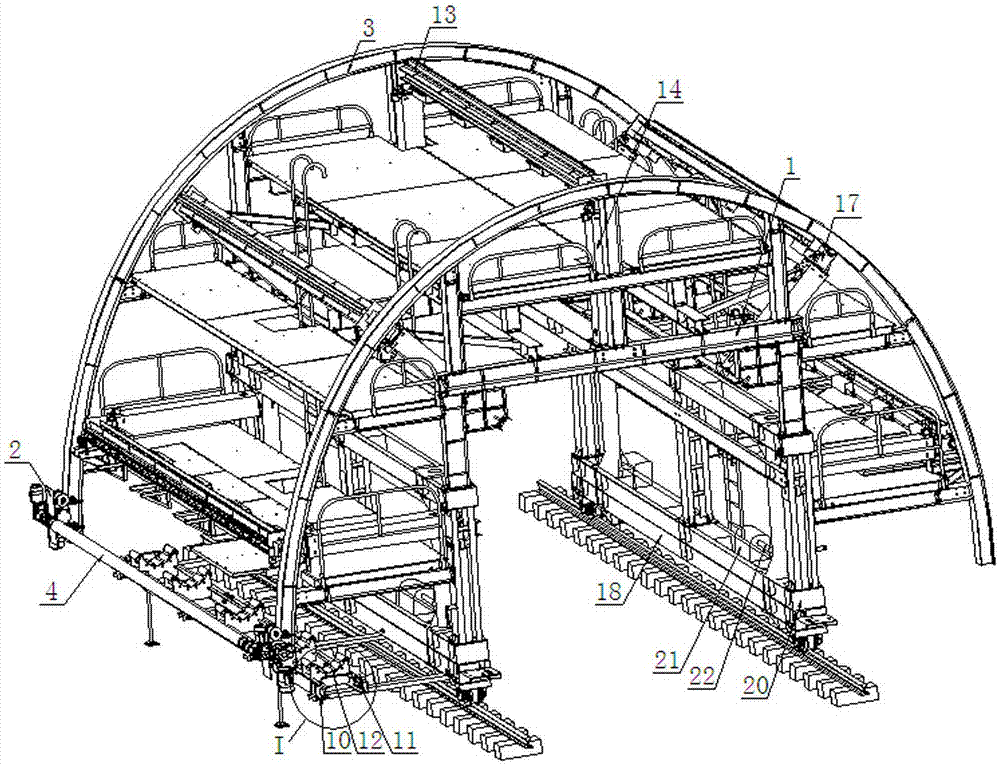

[0028] A jacking mechanism, comprising a jack rod 13, a jacking cylinder 14 and a plurality of vacuum suction cups 15, the number of the jacking cylinders 14 is two sets, and the two sets of jacking cylinders 14 are symmetrically fixed on the mast 1 of the trolley , the ejector rod 13 has a square structure, and its two ends are respectively fixedly connected with the piston rods of two sets of jacking cylinders 14 , and the plurality of vacuum suction cups 15 are evenly fixed on the ejector rod 13 for absorbing the waterproof material 23 .

[0029] Further, in order to prevent the waterproof material 23 that is lifted to the inner wall of the tunnel from slipping when the vacuum chuck 15 loses its adsorption force, a plurality of spring seats 24 are evenly arranged on the push rod 13, and the spring seats 24 and the vacuum chuck 15 is located on the same face of the push rod 13, and the height of the spring seat 24 is higher than that of the vacuum chuck 15. In this way, when...

Embodiment 2

[0037] A trolley using the above-mentioned jacking mechanism also includes a door frame 1, a conveying mechanism, a mobile locking mechanism and two walking trolleys 2, and two symmetrical arc-shaped rails 3 are fixedly arranged on the door frame 1, so that The two walking trolleys 2 described above are arranged symmetrically on two arc-shaped rails 3; the conveying mechanism includes a bracket and a reel 4, and the bracket is arranged at the bottom of the door frame 1 to support the waterproof material 23, and the reel The cylinder 4 is rotated and arranged on two walking trolleys 2 for winding the waterproof material 23 on the bracket; the moving locking mechanism is arranged at the lower part of the door frame 1 for horizontal movement, up and down movement of the door frame 1 and during construction. locking position.

[0038] In this embodiment, the conveying mechanism further includes two motors, and the two motors are symmetrically fixed on the two trolleys 2 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com