Automatic coal-cutting stimulation system for analog simulation experiment

A similar simulation experiment and simulation system technology, applied in the field of automatic coal cutting simulation system, can solve the problems of non-compliance with similar mining speed, large impact on results, etc., so as to save manual work and improve scientificity , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

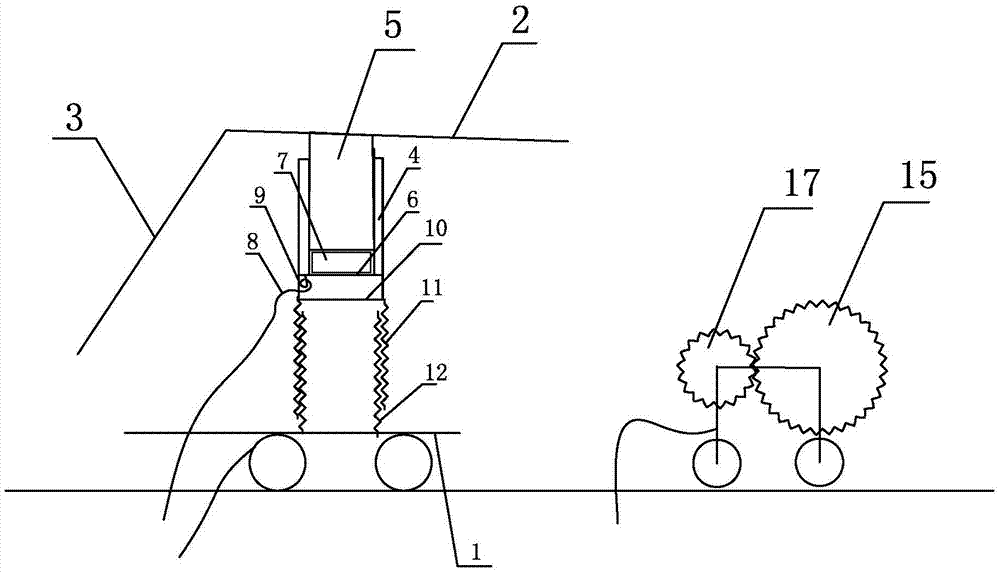

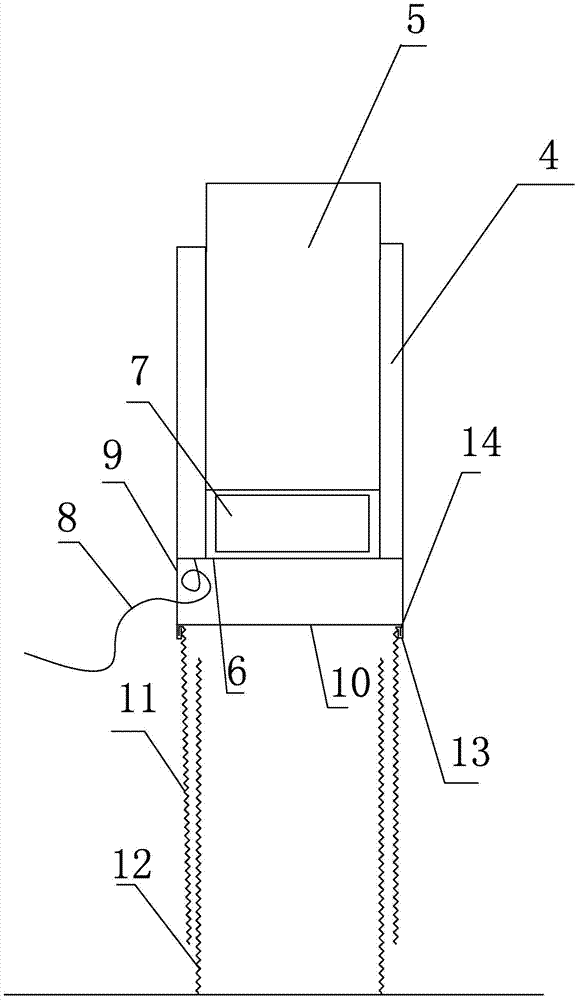

[0039] like Figure 1 ~ Figure 4 As shown, an automatic coal cutting simulation system used for similar simulation experiments is set in a similar simulation model. The similar simulation model includes a frame body, a coal seam set on the frame body, and support rods set on both sides of the bottom of the frame body. Set in other rock formations above and below the coal seam, the automatic coal cutting simulation system used for similar simulation experiments is set in the coal seam and runs on the support rods. The automatic coal cutting simulation system used for similar simulation experiments includes coal mining simulation devices and located at The hydraulic support simulation device on the rear side, the hydraulic support simulation device includes a bottom plate 1, a top plate 2, a stress gauge, a driving device and a baffle 3, wherein the top and bottom of the stress gauge are connected to the top plate 2 and the bottom plate 1 respectively, and the baffle The upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com