Low-pressure gas well two-fluid supersonic atomization drainage gas recovery system and process thereof

A drainage gas production, supersonic technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of low gas flow rate, inability to perform atomization, restricting gas well production, etc., to improve gas production rate , Prevent clogging, good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

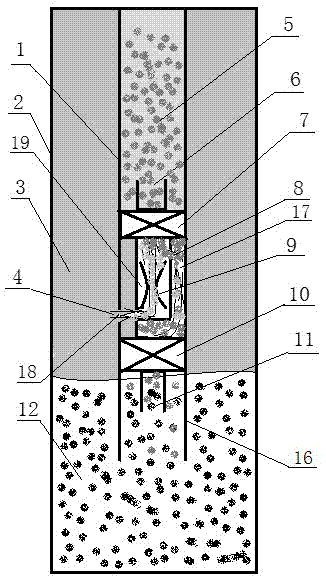

Embodiment 1

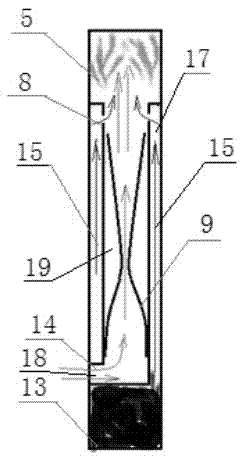

[0042] The invention analyzes the reason why the supersonic atomizer cannot realize atomization in the well, and optimizes it to make it a special technology for atomization and liquid drainage. First, through the theory of fluid mechanics, the sufficient and necessary conditions for atomization in the gas well are obtained. The atomizer in the well can only atomize normally and eliminate the liquid accumulation in the well only if the atomizer in the well meets two conditions, that is, the inlet pressure of the atomizer must be greater than the outlet pressure. More than twice; atomized particle size 30-50um.

[0043] Due to the compressibility of gas, under a certain gas pressure difference on the ground, the technical parameters that can be atomized are not applicable when it is placed in a high-pressure environment in the well, and it follows the principle of isentropy. The Laval tube can reach supersonic speed. To achieve supersonic speed, the ratio of the inlet and outle...

Embodiment 2

[0060] On the basis of Embodiment 1, the Laval tube 9 is arranged in a chamber 19, the upper end of the chamber 19 communicates with the atomization outlet 6, and the chamber 19 is located at the supersonic part of the Laval tube 9 The side wall of the chamber 19 is provided with an effusion inlet 8, and the liquid inlet channel 17 communicates with the effusion inlet 8; the chamber 19 is provided with a through hole on the side wall at the entrance of the lower end of the Laval tube 9, so that The air intake channel 18 communicates with the through hole. The oil pipe 1 is provided with a throttling pipe for controlling the flow rate of the liquid entering the atomizer. The throttle tube coil is installed in the oil pipe 1, and the aperture of the throttle tube is not less than 3mm. The aperture of the throttling tube is 3mm, and its length is 230m-250m. The inlet of the throttling tube is connected with a constant pressure valve, and the constant pressure valve is electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com