Novel coal suction vehicle set for railway tunnel ballast bed

A technology for tunnels and coal trains, applied in track cleaning, construction, cleaning methods, etc., can solve the problems of large distance between the sewage suction port and the track surface, inability to real-time output of sewage, and weak sewage suction ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

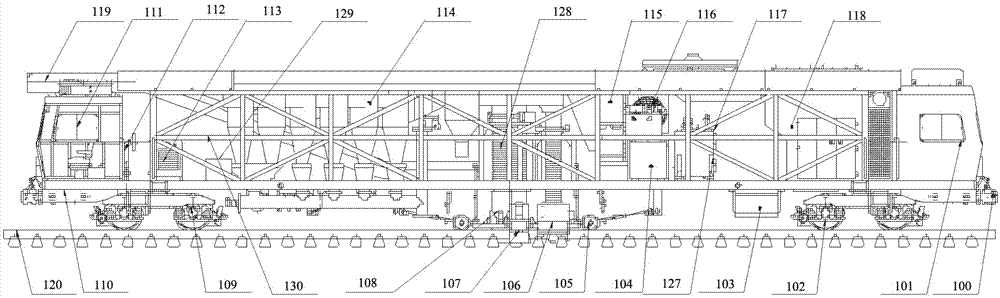

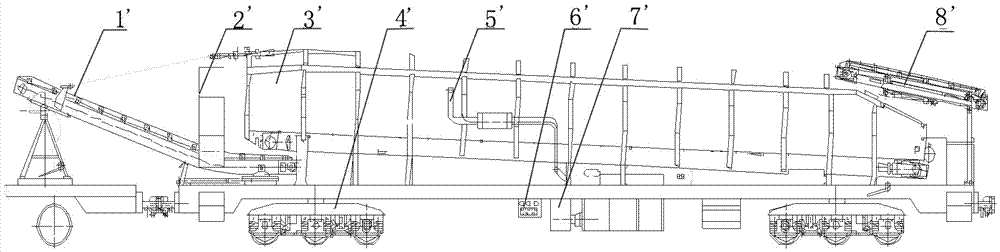

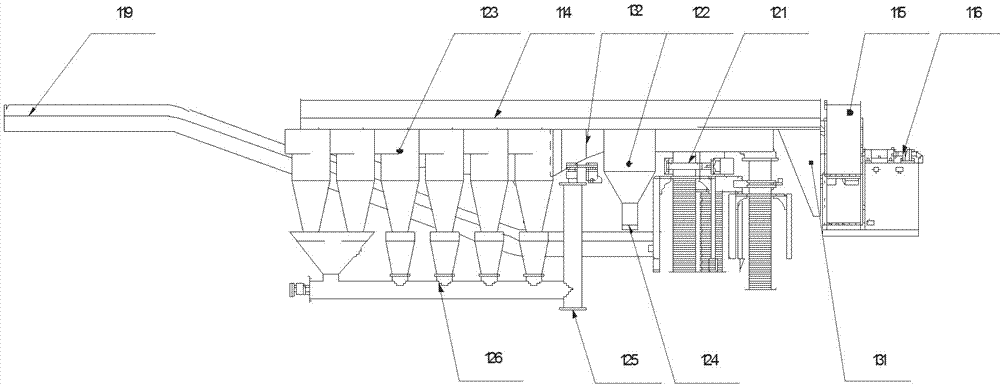

[0087] Example 1.1: Figure 1-Figure 10According to a preferred embodiment of the present invention, the new railway tunnel bed coal suction car group and the structural diagram of the ballast bed coal suction working device, etc., the new railway tunnel bed coal suction car group provided in this embodiment includes interconnected coal suction Vehicle 11' and material vehicle 12', the coal suction vehicle 11' includes a coal suction vehicle frame 110, the coal suction vehicle frame 110 is connected with a front driver's cab 101, a fuel tank, a power room 118, a hydraulic room 117, and an intermediate working device 106 , the left working device 108, the right working device 107, the dust removal system 114, the receiving and transferring device, the tool room 130, the air brake system, the coal suction car frame 110 is also connected with the front bogie 102, the working trolley 105, Diesel tank 103, auxiliary generator set 113, hydraulic radiator 104, material vehicle 12' in...

Embodiment 12

[0110] Embodiment 1.2: A railway tunnel bed coal suction train set, the same as Embodiment 1.1, the difference is that the distance between the side roller brushes 13 is greater than 1.43m.

Embodiment 13

[0111] Embodiment 1.3: A coal-absorbing train set on a railway tunnel bed, which is the same as Embodiment 1.1, except that the distance between the side roller brushes 13 is greater than 1.26m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com