Seven-strand steel cord for engineering tire

A steel cord and engineering technology, applied in textiles, papermaking, textile cables, etc., to prevent cord loosening, prolong service life, and improve resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

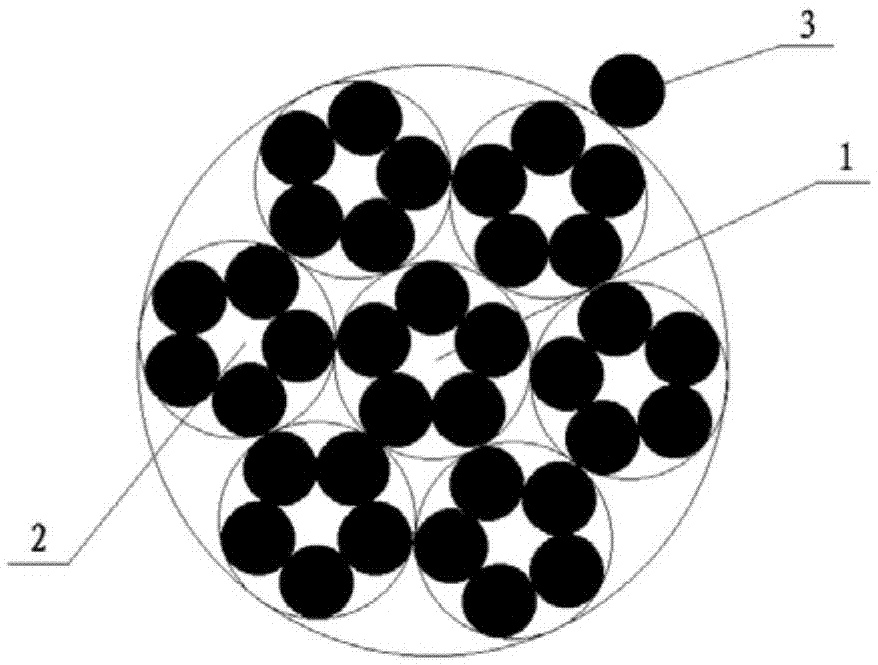

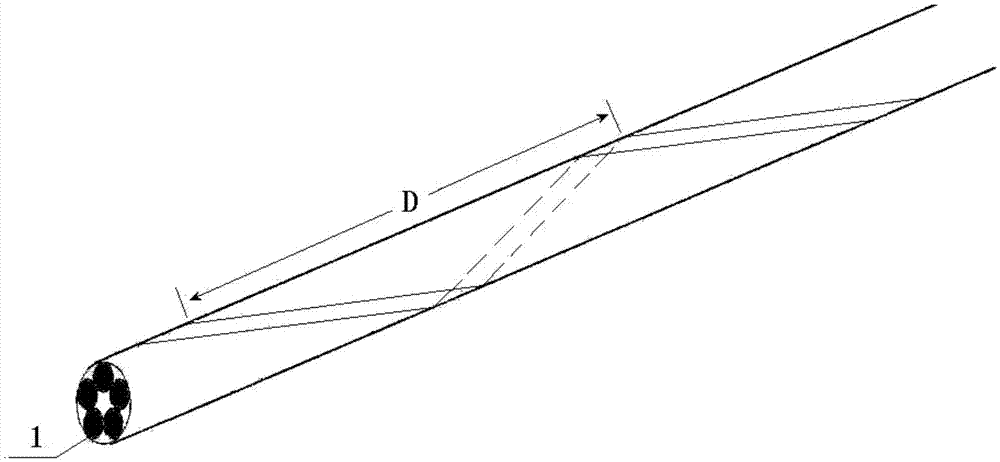

[0026] see Figure 1 to Figure 3 As shown, a seven-strand steel cord for an engineering tire is formed by braiding and twisting steel wires. The diameter of the steel wires is 0.25 mm, which includes a core strand 1, an outer layer strand 2 and a winding steel wire 3. It is formed by adding a winding steel wire 3 after strand braiding and twisting. The twist direction of the wrapping steel wire 3 is S twist, and the twist distance d is 5mm; The structure around the strand 1 has a twist direction of Z twist, a twist distance D of 20mm, and a circular cross section; the core strand 1 and the outer strand 2 are all twisted by five steel wires, and the twist All directions are S twist.

[0027] The embodiment is only for the convenience of understanding the technical solution of the present invention, and does not constitu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com