Water level measurement system and method for washing machine

A water level measurement and washing machine technology, which is applied to other washing machines, washing devices, textiles and paper making, etc., can solve the problems of unclean clothes, waste of water resources, and laborious rotation of washing machines, so as to avoid waste of water resources and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0033] The invention provides a washing machine water level measuring system.

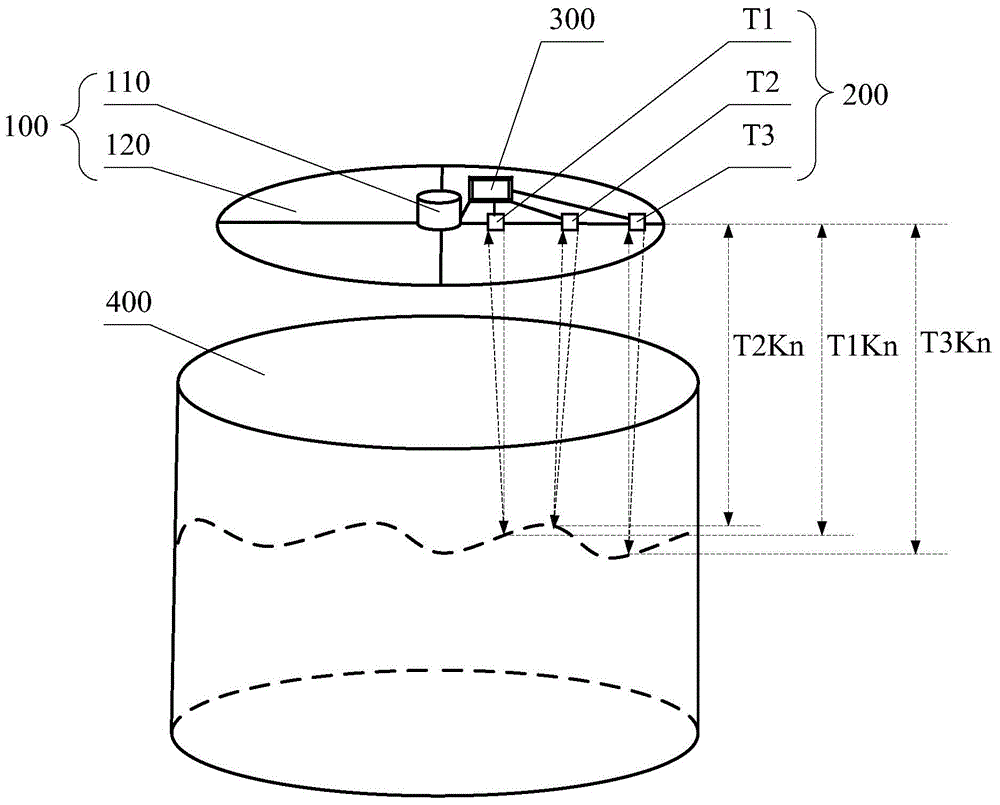

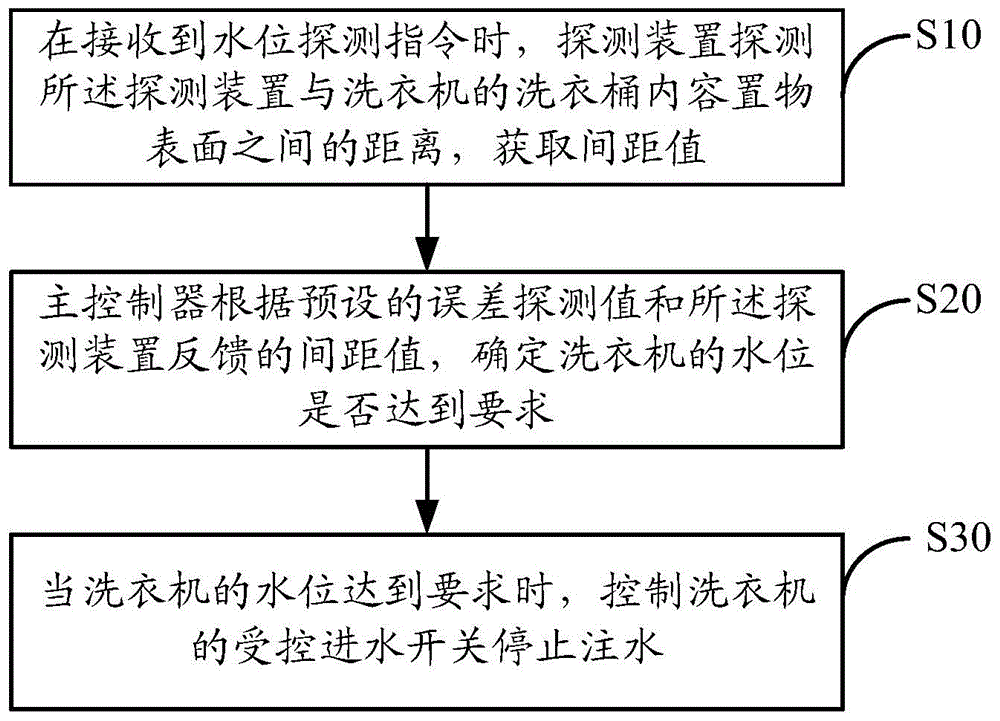

[0034] refer to figure 1 with figure 2 , figure 1 It is a block diagram of a preferred embodiment of the washing machine water level measuring system of the present invention; figure 2 It is a structural schematic diagram of a preferred embodiment of the washing machine water level measuring system of the present invention.

[0035] In a preferred embodiment of the present invention, the washing machine water level measurement system includes a rotating device 100, a detection device 200 and a main controller 300. The rotating device 100 is installed on the inner cover of the washing machine, and the rotating device 100 is located at the same location as the washing tub 400 of the washing machine. on the axis; the detecting device 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com