Insulation thermal shrinkage plastic and insulation thermal shrinkage rubber sleeve

A plastic and heat-shrinkable technology, which is applied in the field of plastic and plastic products, can solve the problems of pungent smell, easy leakage, insulation tape falling off, etc., and achieve good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

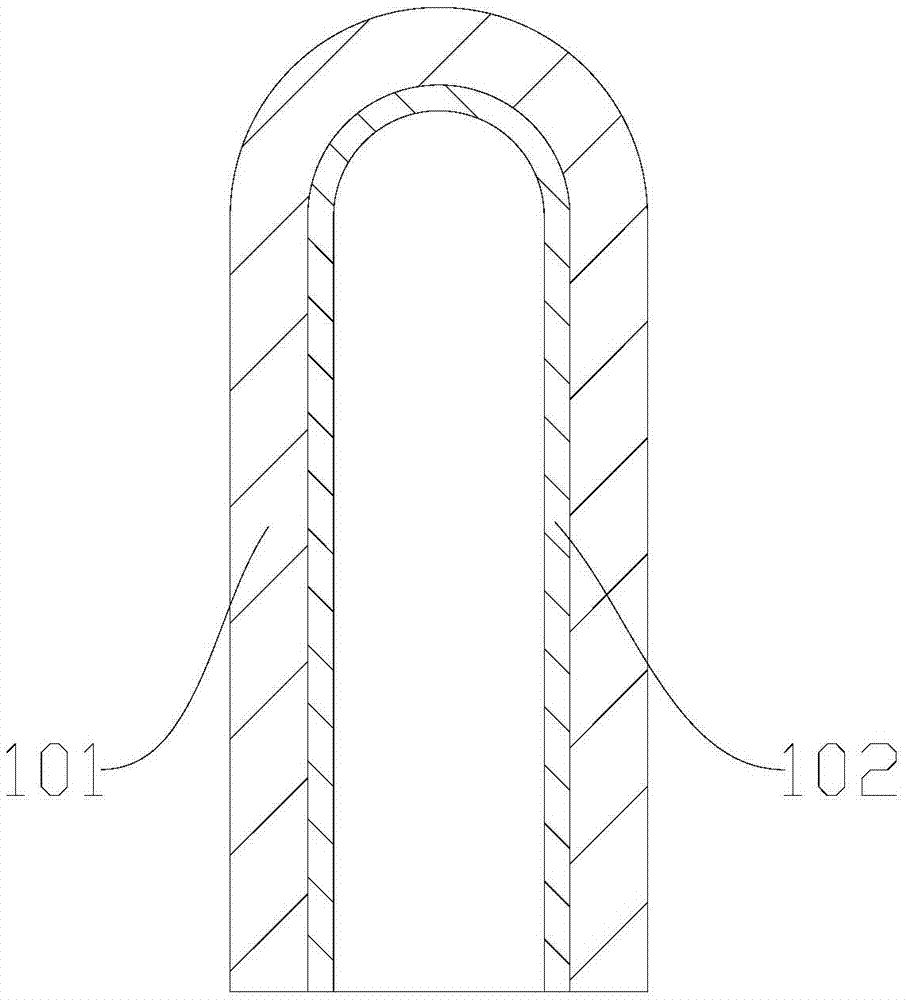

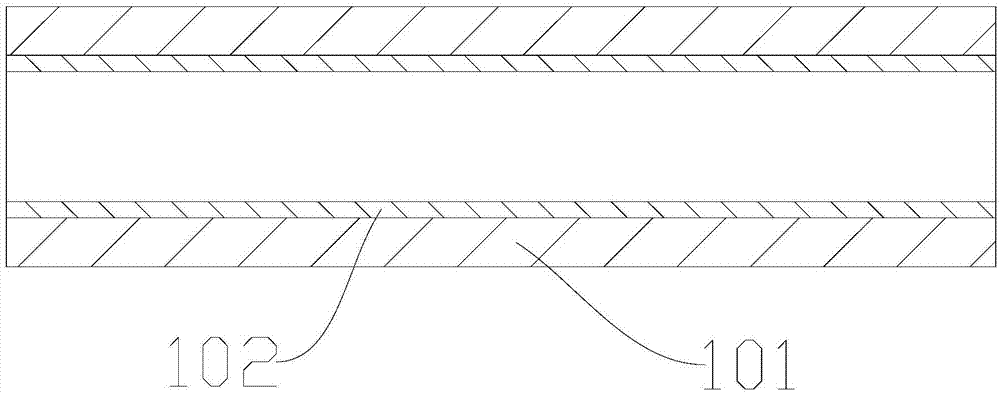

[0029] Such as figure 1 As shown, this embodiment provides an insulating heat-shrinkable rubber sleeve, which includes a plastic layer 101 and an adhesive layer 102. The rubber sleeve is cylindrical as a whole, and the plastic layer 101 constitutes the main structure of the entire rubber sleeve. The entire plastic layer 101 forms a structure with an open end. The adhesive layer 102 is arranged on the inner side of the plastic layer 101, that is, the inside of the rubber sleeve, that is, the inner surface of the plastic layer 101. The adhesive layer 102 is directly arranged on the plastic layer 101 by coating. The inner surface of the plastic layer 101.

[0030] The plastic layer 101 is made of insulating heat-shrinkable plastic. The insulating heat-shrinkable plastic includes 40 parts by weight of polyolefin resin, 15 parts by weight of flame retardant, 1 part by weight of antioxidant, and 1 part by weight of methyl mercaptan. Tin, 1 part by weight of bis(2-ethyl)hexyl sebacate, ...

Embodiment 2

[0034] Such as figure 1 As shown, this embodiment provides an insulating heat-shrinkable rubber sleeve, which includes a plastic layer 101 and an adhesive layer 102. The rubber sleeve is cylindrical as a whole, and the plastic layer 101 constitutes the main structure of the entire rubber sleeve. The entire plastic layer 101 forms a structure with an open end. The adhesive layer 102 is arranged on the inner side of the plastic layer 101, that is, the inside of the rubber sleeve, that is, the inner surface of the plastic layer 101. The adhesive layer 102 is directly arranged on the plastic layer 101 by coating. The inner surface of the plastic layer 101.

[0035] The plastic layer 101 is made of insulating heat-shrinkable plastic, which includes 45 parts by weight of polyolefin resin, 20 parts by weight of flame retardant, 1.5 parts by weight of antioxidant, and 2 parts by weight of methyl mercaptan. Tin, 1.5 parts by weight of di(2-ethylhexyl) sebacate, 11 parts by weight of high ...

Embodiment 3

[0039] Such as figure 1 As shown, this embodiment provides an insulating heat-shrinkable rubber sleeve, which includes a plastic layer 101 and an adhesive layer 102. The rubber sleeve is cylindrical as a whole, and the plastic layer 101 constitutes the main structure of the entire rubber sleeve. The entire plastic layer 101 forms a structure with an open end. The adhesive layer 102 is arranged on the inner side of the plastic layer 101, that is, the inside of the rubber sleeve, that is, the inner surface of the plastic layer 101. The adhesive layer 102 is directly arranged on the plastic layer 101 by coating. The inner surface of the plastic layer 101.

[0040] The plastic layer 101 is made of insulating heat-shrinkable plastic. The insulating heat-shrinkable plastic includes 50 parts by weight of polyolefin resin, 22.5 parts by weight of flame retardant, 2 parts by weight of antioxidant, and 2.5 parts by weight of methyl mercaptan. Tin, 2 parts by weight of di(2-ethyl)hexyl seba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com