A kind of method for continuously preparing cellulose ether

A technology of cellulose ether and cellulose, which is applied in the field of continuous preparation of cellulose ether, can solve the problems of harming human health and hindering the characteristics of cellulose ether, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

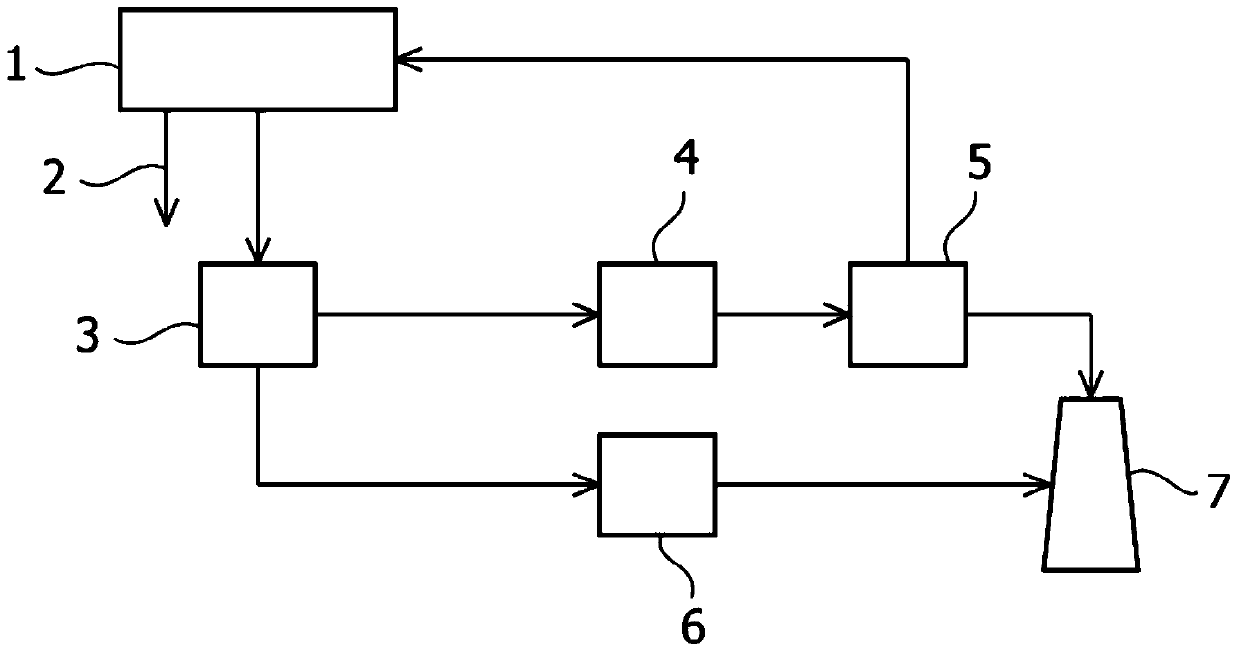

Method used

Image

Examples

Embodiment 1

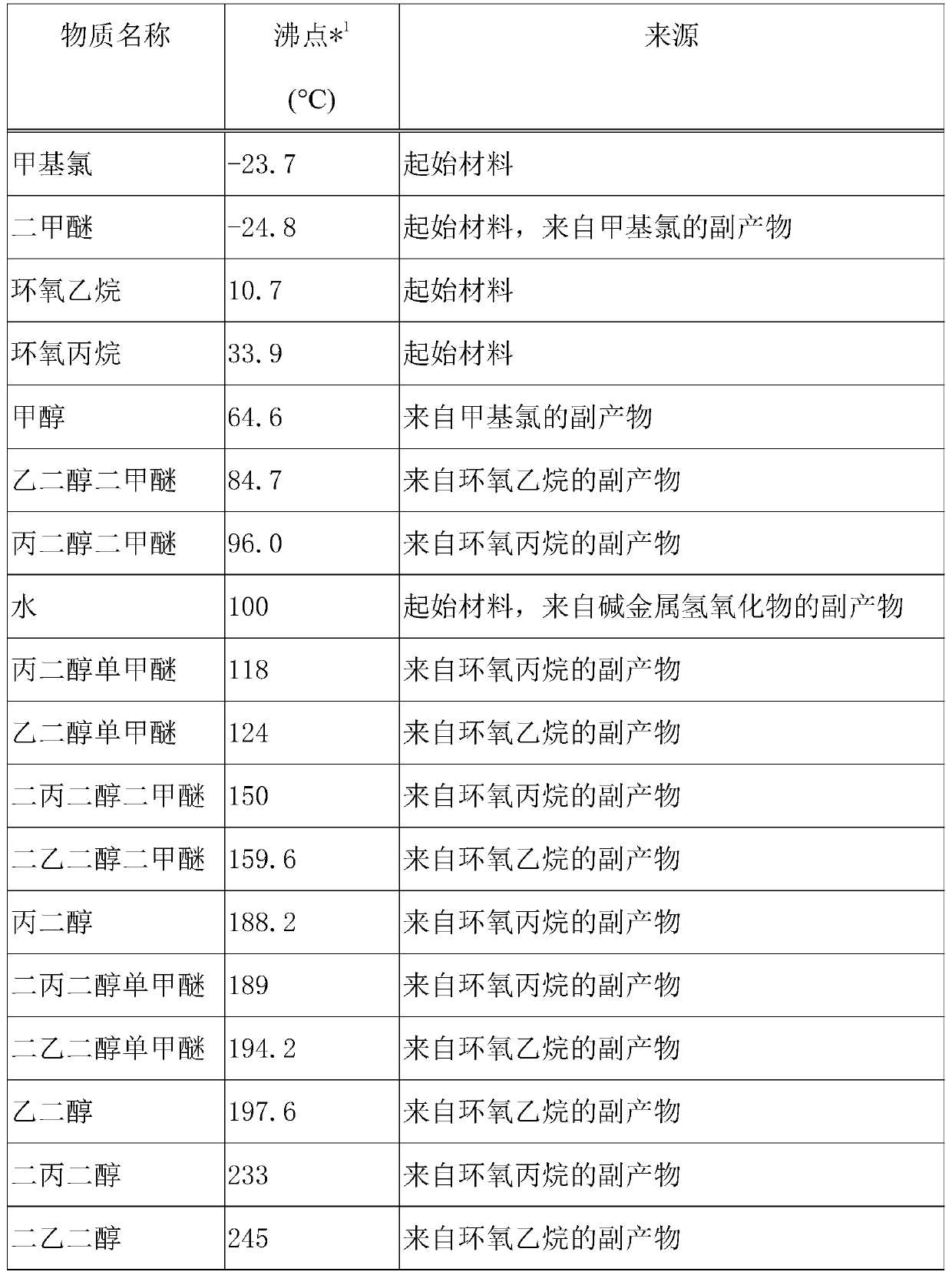

[0053] As a first preparation of cellulose ether, 100 parts by weight of pulp powder were placed in an autoclave with an internal stirrer, and the autoclave was fully purged with nitrogen. With stirring at 60°C, 45 parts by weight of dimethyl ether and 250 parts by weight of 49% by weight sodium hydroxide aqueous solution were simultaneously sprayed into the pulp in the autoclave over 20 minutes to prepare Alkaline cellulose. Then, 160 parts by weight of methyl chloride and 50 parts by weight of propylene oxide were additionally added, and reacted at 60° C. to 90° C. for 2 hours.

[0054] The exhaust gas after the completion of the reaction was recovered by using a partial condenser adjusted to a temperature of 20° C. and a recovery pressure of 2.0 MPa. The unintended liquid components liquefied in the partial condenser are recovered to the storage tank. The liquid components in the partial condenser were analyzed using a gas chromatograph manufactured by Shimadzu Corporatio...

Embodiment 2

[0058] Incineration was carried out in the same manner as in Example 1 except that some components to be recycled were incinerated together with components not to be recycled in the combustion furnace. Specifically, the liquid in the storage tank storing the liquid components that are not intended to be reused after being separated by the partial condenser and the liquefied gas components in the recovery tank are incinerated in the combustion furnace, so The liquefied gas components have not been reused in the second cellulose ether preparation after being separated with a partial condenser and liquefied with a total condenser. The object to be incinerated in the furnace contains 60% by weight of liquefied gas components from the recovery tank and 40% by weight of liquid from the storage tank.

[0059]The furnace temperature was 950°C. The liquefied gas component of the solution of dimethyl ether and unreacted methyl chloride is supplied from the recovery tank to the combusti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com