Preparation method of concrete internal curing agent

An internal and curing agent technology for concrete, applied in the field of concrete admixtures, can solve the problems of high water absorption rate, reduced concrete workability, high water absorption rate, delaying the rate of absorbing mixing water, solving concrete workability and self-shrinking phase Contradictions, the effect of increasing the moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

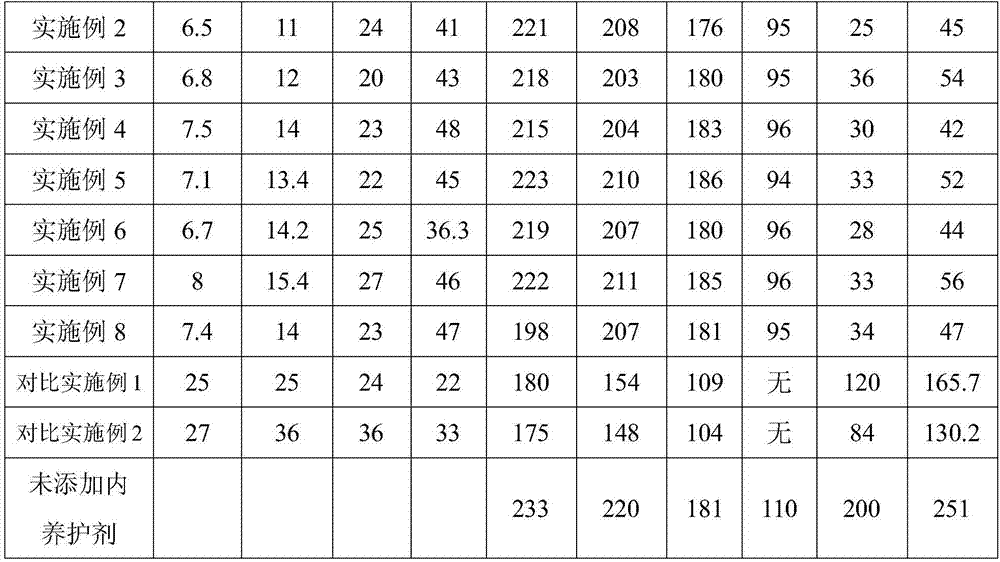

Examples

Embodiment 1

[0028] A preparation method for concrete internal curing agent, comprising the following steps:

[0029] (1) Add 23.67g of acrylamide, 66.67g of methyl methacrylate, 361.36g of ethanol, 0.4517g of N,N'-methylenebisacrylamide and 2.71g of azobisisobutyronitrile into a four-necked flask and stir well , heated to 70°C and reacted for 4 hours, and the resulting gel was routinely treated to obtain a shell material with a hydrophobic structure of 150-200 mesh.

[0030] (2) Mix 128g of deionized water, 36g of acrylic acid, and 16g of sodium hydroxide evenly, control the neutralization temperature <30°C, and add 0.36g of N,N'-methylenebisacrylamide, 0.32g of potassium persulfate and 0.04g of Sodium bisulfite, then add 0.9g of shell material with a hydrophobic structure and soak for 30 minutes, filter and put it in an oven for 3 hours at 60°C to react for 3 hours, and finally obtain a 100-200 mesh concrete internal curing agent after conventional post-treatment.

Embodiment 2

[0032] A preparation method for concrete internal curing agent, comprising the following steps:

[0033] (1) Add 20.3g of acrylamide, 81.43g of ethyl methacrylate, 237.37g of ethanol, 1.02g of N,N'-methylenebisacrylamide and 2.035g of azobisisobutyronitrile into a four-necked flask and stir well , heated to 60°C and reacted for 7 hours, and the resulting gel was routinely treated to obtain a shell material with a hydrophobic structure of 150-200 mesh.

[0034] (2) Mix 68g of deionized water, 36g of acrylic acid, and 16g of sodium hydroxide evenly, control the neutralization temperature <30°C, and add 1.08g of N,N'-methylenebisacrylamide, 0.032g of potassium persulfate and 0.004g of Sodium bisulfite, then add 2.4g of shell material with a hydrophobic structure and soak for 60 minutes, filter and put it in an oven for 1 hour at 80°C to react for 1 hour, and finally obtain a 100-200 mesh concrete internal curing agent after conventional post-treatment.

Embodiment 3

[0036] A preparation method for concrete internal curing agent, comprising the following steps:

[0037] (1) Add 23.67g of acrylamide, 57.34g of methyl acrylate, 361.36g of ethanol, 1.3551g of ethylene glycol dimethacrylate and 2.71g of azobisisobutyronitrile into a four-necked flask and stir evenly, and heat to 55 React at 6°C for 8 hours, and the resulting gel can be treated conventionally to obtain a shell material with a hydrophobic structure of 150-200 mesh.

[0038] (2) Mix 84g of deionized water, 36g of acrylic acid, and 16g of sodium hydroxide evenly, control the neutralization temperature <30°C, and add 0.5g of N,N'-methylenebisacrylamide, 0.32g of sodium persulfate and 0.035g of Sodium bisulfite, then add 1.36g of shell material with a hydrophobic structure and soak for 45 minutes, filter and put it in an oven for 2 hours at 70°C to react for 2 hours, and finally obtain a 100-200 mesh concrete internal curing agent after conventional post-treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com