Automatic spinning cake taking device for viscose filaments

A viscose filament and silk cake technology, which is applied in the field of automatic silk cake taking device and automatic equipment for taking and placing the silk cake, to achieve good stability and continuity, and to ensure the effect of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

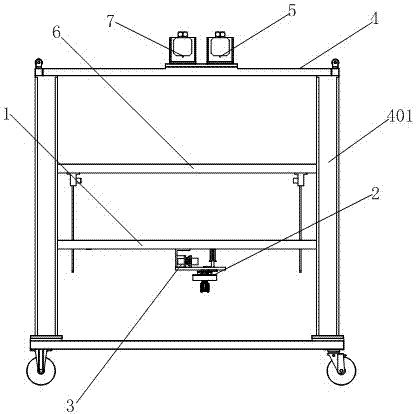

[0030] This embodiment relates to a kind of automatic silk cake device for viscose filament, such as figure 1As shown in the structure, it includes a frame body 4 provided with a silk cake lifting device 1, a silk cake hand grasping device 2 and a silk cake horizontal power device 3, and the column 401 of the frame body 4 is for the vertical movement of the silk cake lifting device 1. Guide rail structure, on the top of the frame body 4 is provided with the first motor 5 to control the silk cake lifting device 1; On the lifting device 1; the silk cake hand grasping device 2 is a silk cake fixing part that moves with the silk cake horizontal power device 3.

[0031] Since this embodiment is designed for the R535A spinning machine, its structure also includes a large cover lifting device 6 located above the silk cake lifting device 1, and the large cover lifting device 6 is a moving part that slides vertically along the frame body 4 column 401 , the top of the frame body 4 is p...

Embodiment 2

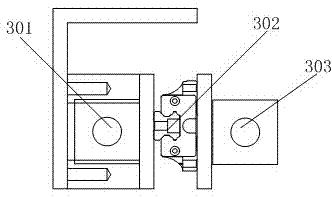

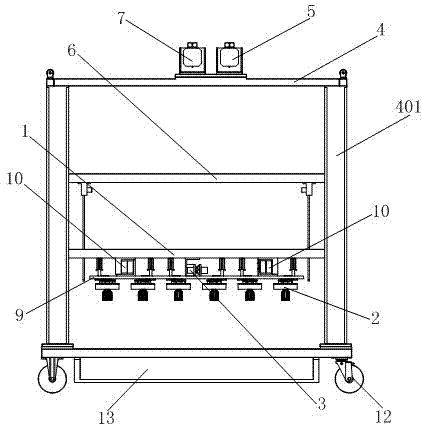

[0036] In this embodiment, on the basis of Embodiment 1, more than one silk cake hand grasping device 2 is added, and a fixed frame 9 for fixing all silk cake hand grasping devices 2 is provided, and the moving piston of the second cylinder 303 is fixed on the fixed frame 9 superior. From image 3 , Figure 4 As can be seen from the front view and the left view of the equipment shown, the present embodiment is provided with eighteen silk cake hand grasping devices 2, and the fixed frame 9 adopts a rectangular frame structure welded by steel pipes, and all the silk cake hand grasping devices 2 are simultaneously to fix. During use, when the fixed frame 9 moves with the moving piston of the second cylinder 303, the 18 silk cake hand grasping devices 2 also move simultaneously, Figure 5 It is a schematic diagram of the distribution of eighteen silk cake hand-holding devices 2 in this embodiment.

[0037] In order to ensure that the eighteen silk cake hand grasping devices 2 ...

Embodiment 3

[0039] The present embodiment proposes the structure of the silk cake hand grasping device 2 on the basis of embodiment 2, as Figure 6 As shown, the silk cake hand grasping device 2 includes a connecting rod mechanism 201, a suction cup electromagnet 202 and a hand grasping power cylinder 203 connected in sequence. The suction cup electromagnet 202 is a power component for absorbing the silk cake inner sleeve 11. The sleeve 11 is a hollow structure located on the outside of the silk cake and embedded with an iron ring; the linkage mechanism 201 is a telescopic component acting on the inside of the silk cake; the power cylinder 203 is fixed on the fixed frame 9 by hand.

[0040] In this embodiment, the frame body 4 is provided with a pulley 12 for moving, and the bottom of the frame body 4 is also provided with an electrical control box 13, and the electrical control components involved in this equipment are all arranged in the electrical control box 13, further through PLC pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com