Molten aluminum ladle transport cart

A transport vehicle and aluminum water bag technology, which is applied in the direction of transporting objects, transportation and packaging, and vehicles used for freight, can solve the problems of bulky vehicles, high vehicle costs, and potential safety hazards, and achieve a compact overall structure and reduce The effect of vehicle cost and steering convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

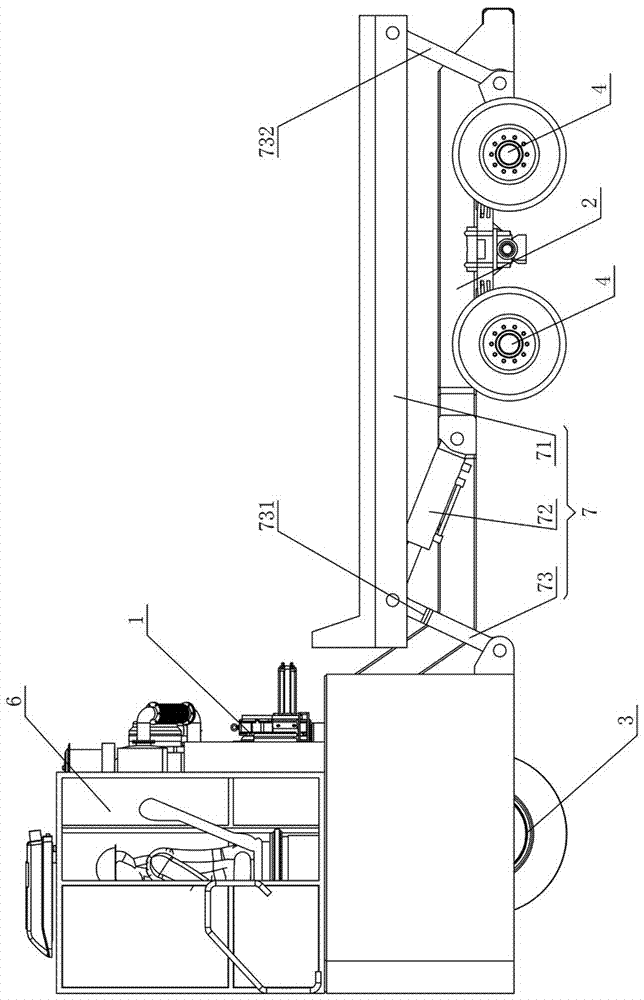

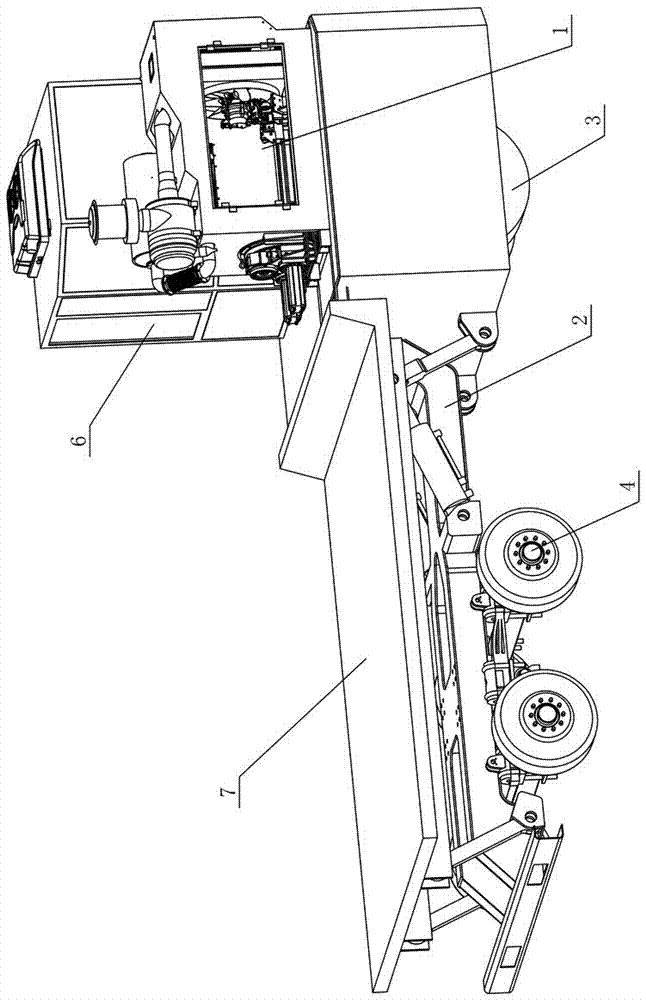

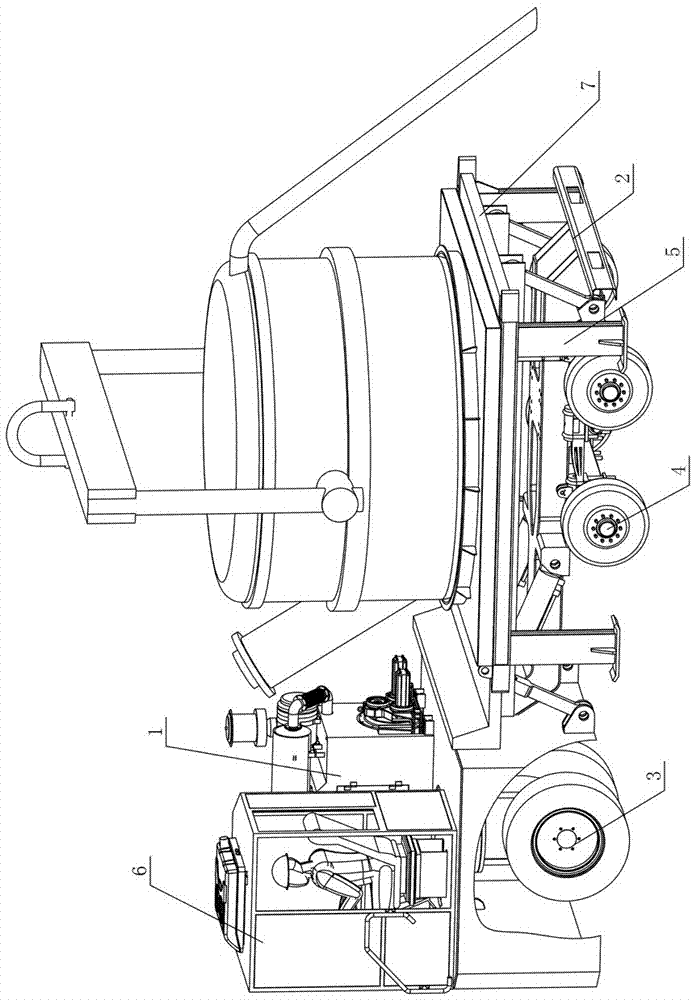

[0027] Figure 1 to Figure 6 Shown is an embodiment of the aluminum ladle transport vehicle of the present invention, the transport vehicle comprises a power assembly 1, a vehicle frame assembly 2, a steering drive front axle 3, a rear axle 4, a frame attachment 5 and a cab 6, and the power The assembly 1 and the cab 6 are installed on the top of the front end of the frame assembly 2, the steering drive front axle 3 and the rear axle 4 are separately installed on the bottom of the front and rear ends of the frame assembly 2, and the rear section of the frame assembly 2 is installed There is a lifting platform 7, and the frame attachment 5 is assembled on the lifting platform 7. When in use, first place the aluminum water bag on the frame attachment 5, then adjust the posture of the vehicle by steering the front axle 3, pour the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com