Tape discharging mechanism and tape attaching device

A technology of discharging mechanism and tape, applied in lamination device, thin material processing, transportation and packaging, etc., can solve the problems of high precision of narrow tape attachment, difficult operation of narrow tape, and increase of product defect rate, etc. The effect of saving demand space, good market prospect and high attachment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides an adhesive tape discharging mechanism, which can automatically complete the tape discharging process with high efficiency and high precision by using a coiled material tape in the form of a coiled material structure. The reel tape mentioned here includes a protective film and an adhesive tape, and the protective film covers the adhesive side of the adhesive tape to protect the adhesive performance of the adhesive tape.

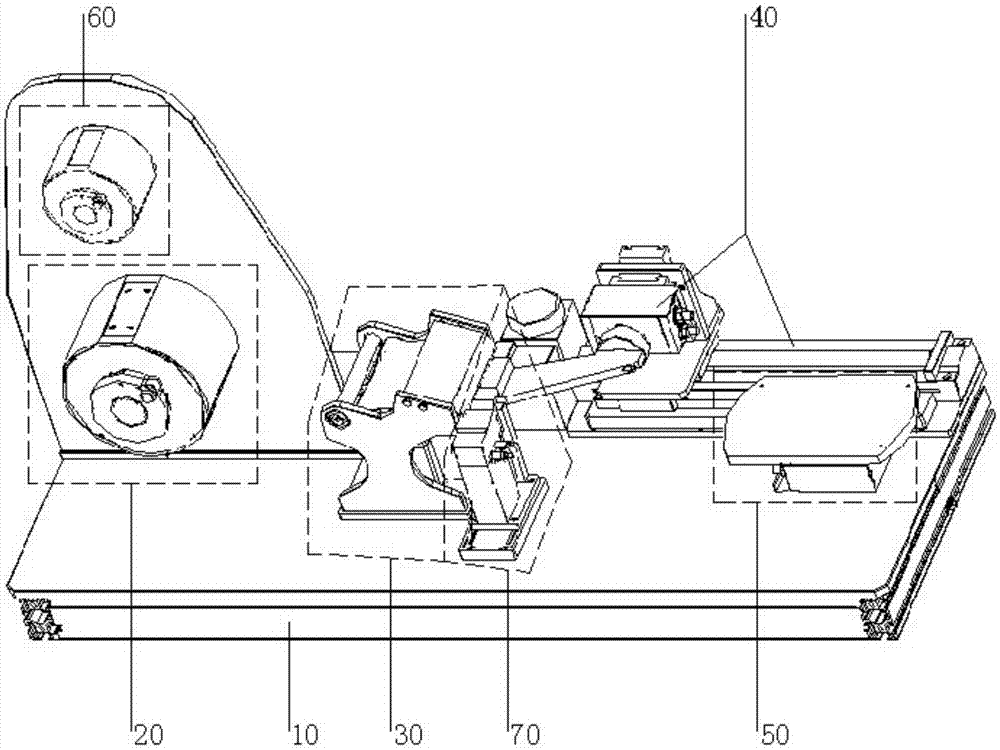

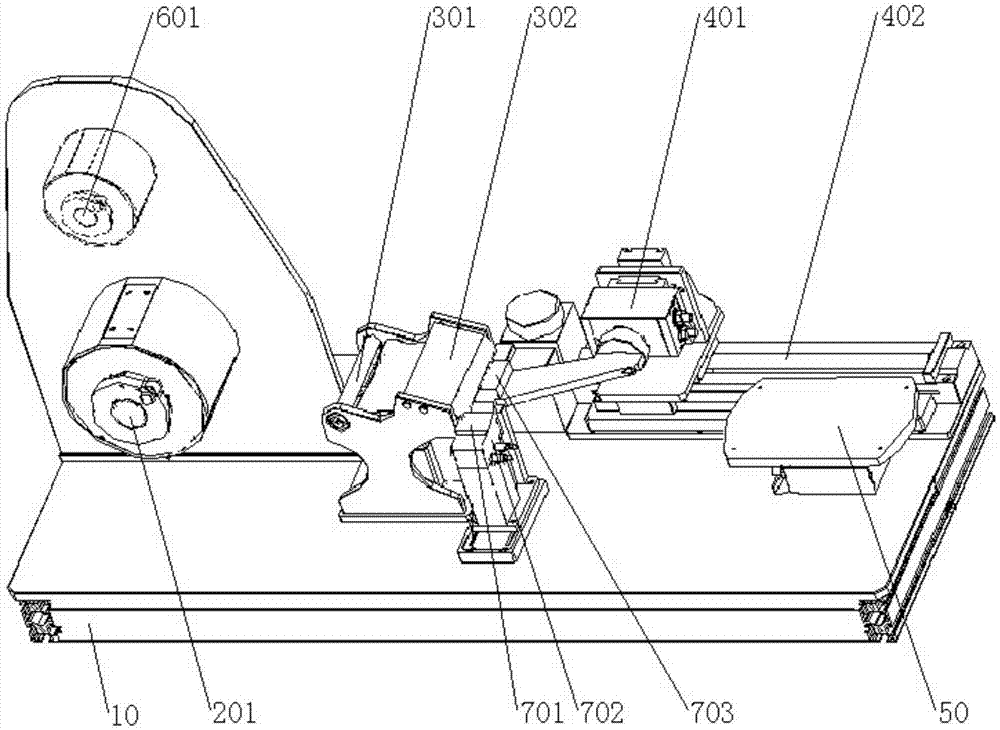

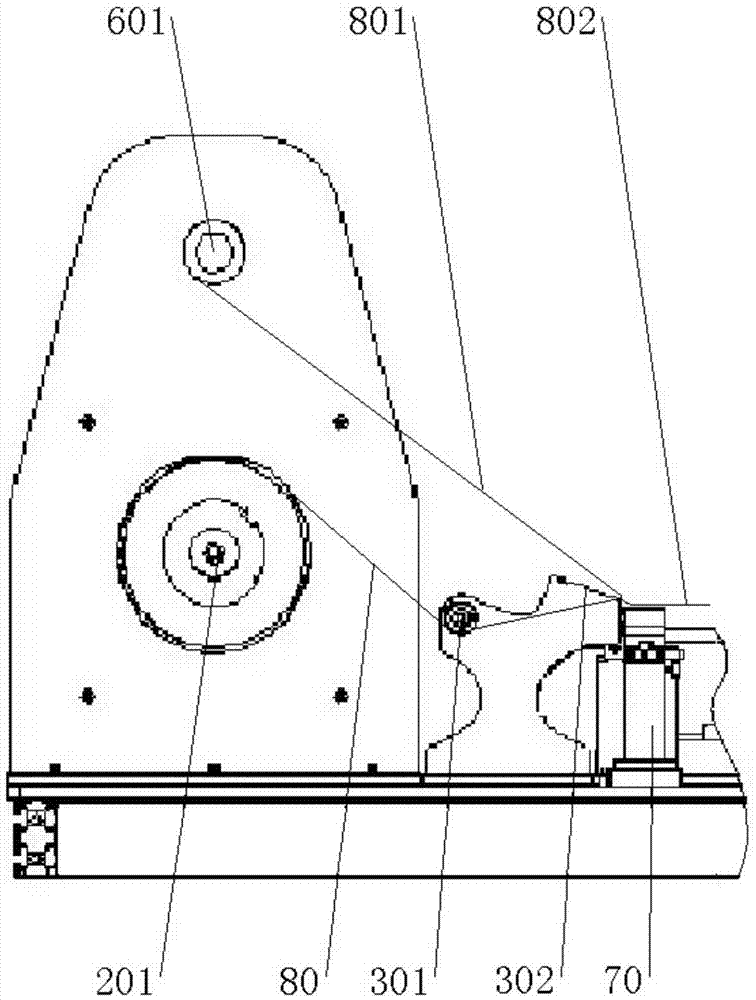

[0049] The adhesive tape discharge mechanism includes a machine table, a coil tape discharge unit and a protective film peeling unit arranged above the machine table, wherein:

[0050] The coil belt discharge unit includes a discharge air-inflating shaft, which is arranged at a relatively front position above the machine table, and is used for rotatingly conveying the coil material belt;

[0051] The protective film peeling unit is arranged at the relative rear of the coil belt discharge unit, and is used for peeling the protec...

Embodiment 2

[0070] This embodiment provides a tape sticking device, the tape sticking device includes a manipulator and the tape discharge mechanism in Embodiment 1, the manipulator is used to attach the tape delivered by the tape discharge mechanism to the surface of the product to be tape .

[0071] The adhesive tape attaching device uses a manipulator to attach the adhesive tape, so that the attachment accuracy is high and the stability is good, and the problems of low manual attachment accuracy, poor stability, serious tape waste, and high product defect rate are solved.

[0072] Tests have shown that the time range for the existing manual sticking of each tape is about 8 to 9 seconds, and the time for sticking each tape with the tape sticking device of this embodiment is about 3.5 seconds, compared with the traditional manual sticking way, the efficiency has been increased by more than 2 times, and the problems of low accuracy, poor stability, serious tape waste and high product defe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com