Manufacture method for guiding carrier roller in guide roller used for backward bending machine

A technology of guiding idler and manufacturing method, which is applied to manufacturing tools, metal processing equipment, feeding devices, etc., can solve the problems affecting the production quality of steel pipes, the deviation of steel pipe transportation, and the easy deviation of the center of gravity, so as to achieve a stable center of gravity and improve Conveying precision, smooth and precise effect of conveying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

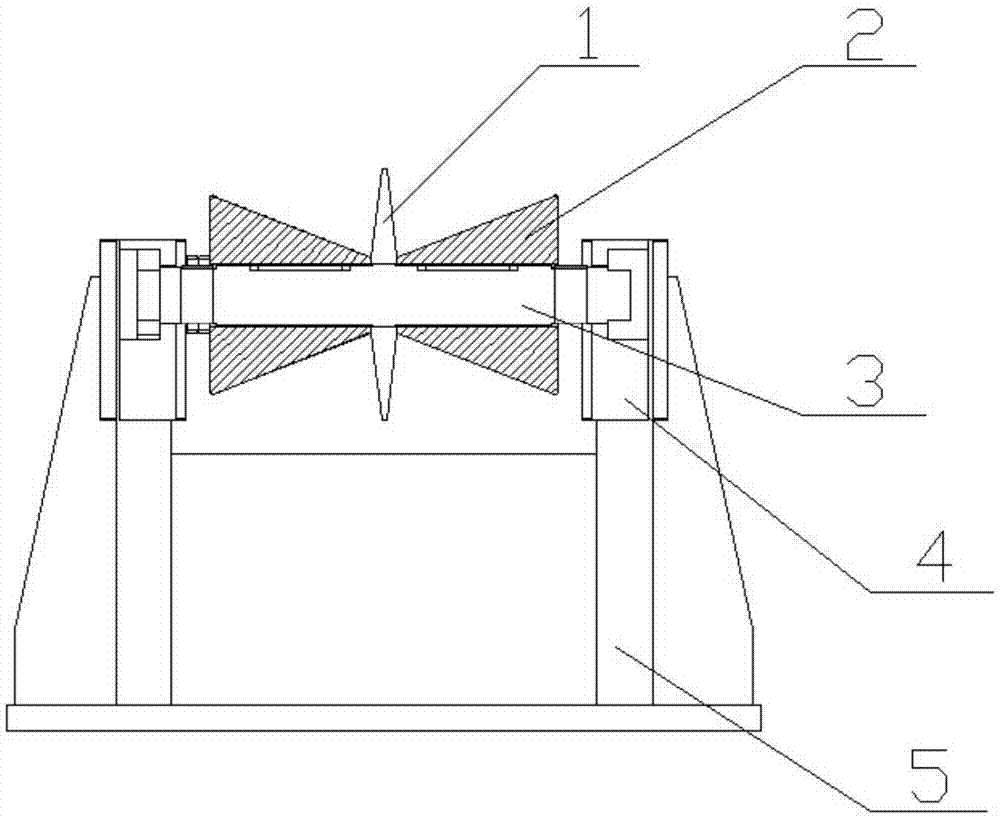

[0040] like figure 1As shown, a guide roller for a back bender includes a guide roller 2, a roller 3, a roller seat 4 and a guide roller frame 5. The roller 3 is provided with a key groove; the guide roller 2 is installed on the roller through a key connection. On the shaft 3, the guide roller 2 and the roller 3 are in interference fit; the roller seat 4 is provided with a sliding bearing; the roller 3 is connected with the roller seat 4 through the sliding bearing, and the roller seat 4 is two symmetrically. Installed on the guide roller frame 5; the guide roller 2 is a truncated cone, and one of the two ends is the upper bottom surface and the other is the lower bottom surface. The inclination angle is 30°; the number of guide rollers 2 is two; the two circular truncated guide rollers 2 are installed on the roller 3 in a way that the upper and lower surfaces are opposite to each other; there is a guide wheel 1 in the middle of the two circular truncated guide rollers 2 ; Th...

Embodiment 2

[0052] A manufacturing method of a guide idler for a guide roller for a back bending machine, the steps of which are:

[0053] A Preparation of raw materials: The components and weight percentages of the materials used in the guide roller are: C: 1.80%, Si: 2.6%, Mn: 0.9%, Cr: 1.10%, S≤0.05%, P≤0.05%, the remainder is Fe;

[0054] B heat treatment: the forging blank in step A is annealed, the annealing temperature is 720 ° C, the temperature is kept for 2 hours, and the air is cooled;

[0055] C Preliminary machining: the forging blank after the heat treatment in step B is preliminarily machined into the overall shape of the guide roller with a lathe;

[0056] D quenching and tempering treatment: heating the guide roller after initial processing in step C to a temperature of 830 ° C, holding for 1 hour, and water quenching;

[0057] E deep processing: fine grinding the outer surface of the guide roller after the quenching and tempering treatment in step D;

[0058] F surfac...

Embodiment 3

[0062] A manufacturing method of a guide idler for a guide roller for a back bending machine, the steps of which are:

[0063] A Preparation of raw materials: The components and weight percentages of the materials used in the guide roller are: C: 2.11%, Si: 1.8%, Mn: 1.3%, Cr: 0.70%, S≤0.05%, P≤0.05%, the balance is Fe;

[0064] B heat treatment: the forging blank in step A is annealed, the annealing temperature is 760 ° C, the temperature is kept for 3 hours, and the air is cooled;

[0065] C Preliminary machining: the forging blank after the heat treatment in step B is preliminarily machined into the overall shape of the guide roller with a lathe;

[0066] D quenching and tempering treatment: heating the guide roller after the initial processing in step C to a temperature of 850 ° C, holding for 2 hours, and water quenching;

[0067] E deep processing: fine grinding the outer surface of the guide roller after the quenching and tempering treatment in step D;

[0068] F sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com