Large heavy-duty open die forging oil press unloading system

A technology of hydraulic press and hydraulic system, which is applied in the driving device of forging press, forging/pressing/hammering machinery, forging/pressing/hammer device, etc., which can solve the problems of shaking of the body, small space, and easy damage of electromagnetic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings.

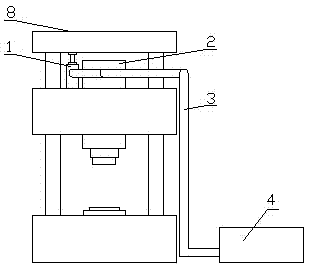

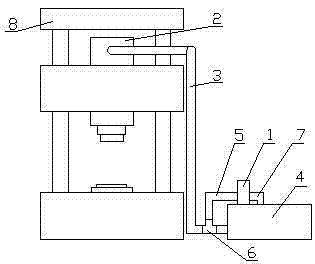

[0012] figure 1 Shown is a schematic diagram of the position of the unloading valve block of the prior art hydraulic press. The unloading valve block 1 is located at the top of the hydraulic press near the oil inlet of the oil cylinder 2. When the pressure is released, the high-pressure oil leaks into the oil tank 8 at the upper end of the unloading valve block 1; the present invention Program such as figure 2 As shown, the unloading valve block 1 is set on the hydraulic pump station 4, and the tee 6 is welded on the oil pipeline 3 near the oil outlet of the hydraulic pump station 4, and the tee 6 passes through the pipeline 5 and the inlet of the unloading valve block 1 Connected, the outlet of the unloading valve block communicates with the hydraulic pump station 4 through the pipeline 7. When the pressure is released, the high-pressure oil is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com