Automatic cleaning equipment for painting line

A self-cleaning and coating line technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problem that the effective utilization rate of equipment cannot reach the expected goal, the output cannot be met, and the cleaning and maintenance time Long and other problems, to achieve the effect of saving working time, improving production efficiency, efficient and synchronous cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

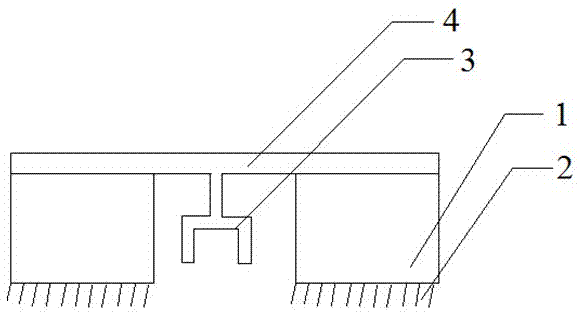

[0013] In order to achieve the above object, the self-cleaning equipment of the coating line is realized by the following technical scheme: the self-cleaning equipment of the coating line comprises a main body 1, a brush 2, a liquid sprayer 3 and a connecting pipe 4, and the brush The brush 2 is connected to the bottom of the main body 1, the two main bodies 1 are respectively connected to the two ends of the connecting pipe 4, and the liquid sprayer 3 is connected to the middle part of the connecting pipe 4; the liquid sprayer 3 is an inverted "Y" shape; The interior of the liquid dispenser 3 is hollow; the specifications of the two bodies 1 are the same; the brush 2 is an artificial brush; the interior of the liquid sprayer 3 has a liquid reservo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com