Continuously-circulating screen vibrating sieve

A technology of sieve and mesh screen, which is applied in the direction of filter sieve, solid separation, grid, etc., can solve the problems of poor self-cleaning ability of the screen, high liquid content in the solid phase, and easy sieve blockage, etc., to achieve self-cleaning ability Strong, low cost, small exciting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

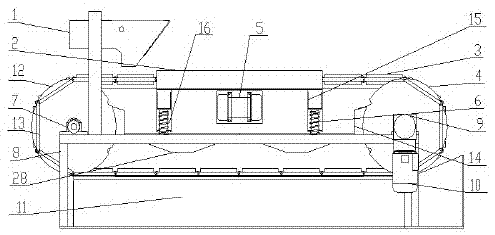

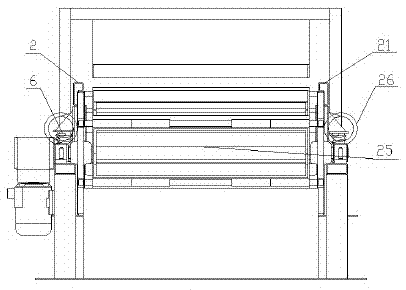

[0016] Further illustrate the present invention below in conjunction with accompanying drawing:

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a continuous circulation screen vibrating screen of the present invention is mainly composed of a screen circulation system, a screen excitation system, a screen circulation drive system and the like. The sieve circulation system is assembled by the sieve plate 3 installed with the sieve, the chain 13, the driving sprocket 4, and the driven sprocket 12; the sieve plate 3 is hinged together through the connecting shaft 18, and the outer surface of the connecting shaft There is a shaft sleeve 19, and the two ends of the connecting shaft are respectively matched with the chain plate 20, the sleeve 22 and the roller 21 to form a chain 13 on both sides, and the chain 13 is wound on two sprockets on each side to form a closed loop structure The sprocket shaft 25 plays the role of supporting the sprocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com