Upwards impact type single-section hammer type crusher

A single-stage hammer crusher technology, applied in grain processing, etc., can solve the problems of shortening the service life of the crusher, easy damage, etc., and achieve the effect of reducing impact, reducing wear of spare parts, and increasing the sputtering range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

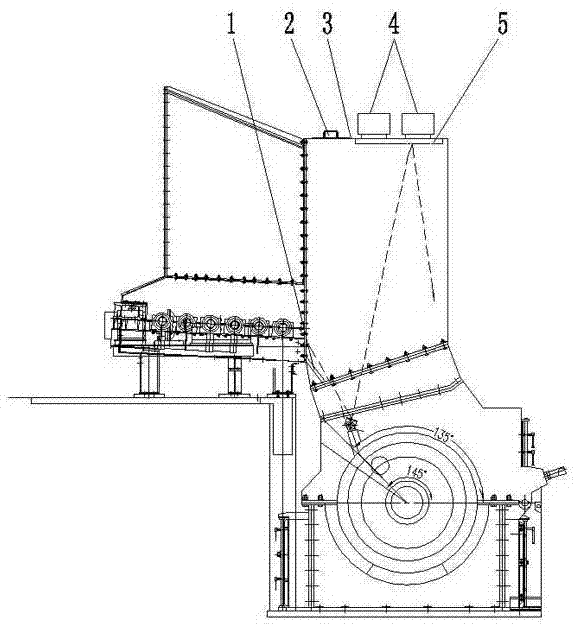

[0008] The specific embodiment of the present invention is that it includes a feeding part and a crushing part, wherein, there is a discharge chute 1 between the feeding part and the crushing part, and the casing in the crushing part is equipped with The upper cover 3, the chain curtain door 2 is arranged on the upper cover, the counterweight 4 is installed on the upper part of the upper cover 3, and the counterattack plate 5 is installed on the lower part of the upper cover 3; The feeding angle is greater than 135° and less than or equal to 145°.

[0009] When working, the material is conveyed by the roller feeder in the feeding part and enters the crushing part. Since the material pallet on the feeding slide 1 is canceled, the feeding angle of the material is changed from 135 degrees to 135-145 degrees. Under the action of gravity, it is directly sent to the front section of the hammer head bracket of the crushing part by the blanking slide 1. Under the impact of the hammer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com