Soymilk fermented feed for feeding weaned suckling pigs and preparation method thereof

A technology of fermented feed and production method, which is applied in the field of feed, can solve the problems of complex production process, low feed digestion and utilization rate, easy to cause diarrhea, etc., and achieve the effect of simplifying the production process, protecting the health of the intestinal tract, and having good active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

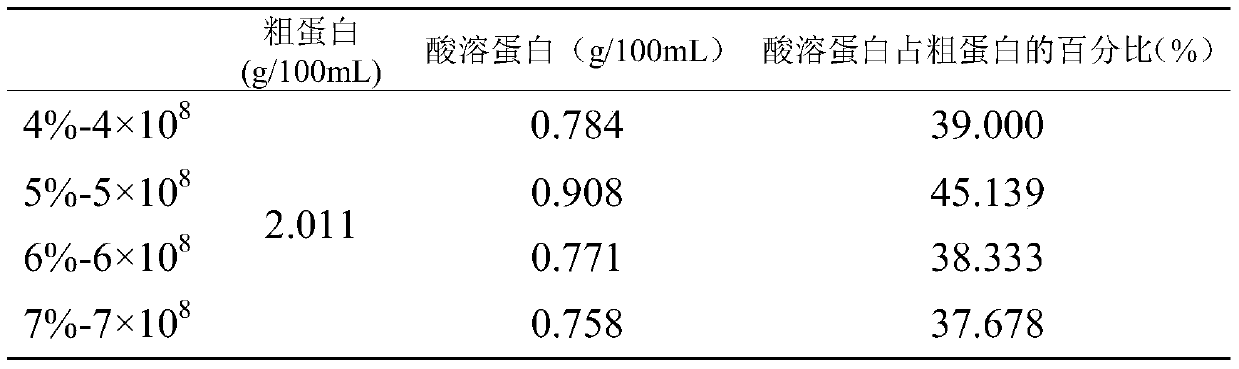

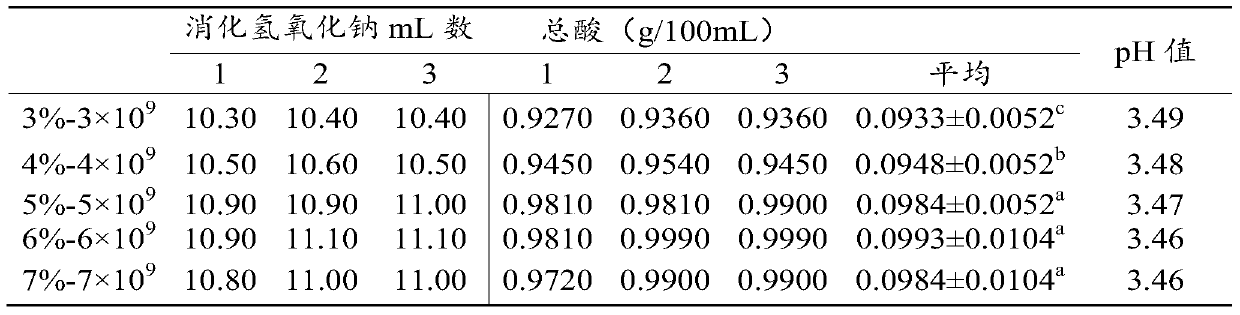

Examples

Embodiment 1

[0045] Weigh 150 parts of soaked soybeans, 750 parts of pure water, 36 parts of glucose, and 90 parts of skimmed milk powder, put the soaked soybeans and pure water in the soymilk machine, and the soymilk machine will mix the soaked soybeans and pure water to make pulp residue, and Glucose and skim milk powder are added to the mixed pulp residue for deployment, and then the prepared mixed pulp residue is put into a homogenizer for homogenization. The homogenization step can make the soaked soybeans in the pulp residue granulated and homogenized, which can Reduce the size of the dispersion and improve the uniformity of the distribution of the dispersion. Keep homogenizing at a pressure of 25 MPa for 10 minutes. After 10 minutes, place the homogenized mixed pulp residue at 105-121° C. for sterilization, sterilize for 30 minutes, and then cool to make a liquid medium.

[0046] First place Bacillus subtilis in broth medium to activate to make broth seed liquid, and at the same tim...

Embodiment 2

[0051] In the present embodiment, it is preferred that the weight fraction ratio of soaked soybeans and pure water is 1:7. Weigh 150 parts of soaked soybeans, 1050 parts of pure water, 48 parts of glucose, and 120 parts of skim milk powder, and place the soaked soybeans and pure water In the soymilk machine, the soymilk machine will soak soybeans and pure water to mix pulp residue, and add glucose and skimmed milk powder to the mixed pulp residue for deployment, and then put the prepared mixed pulp residue into the homogenizer for homogenization Homogenize, keep the pressure at 30MPa and homogenize for 8 minutes. After 8 minutes, place the homogenized mixed pulp residue at 105-121°C for sterilization, sterilize for 30 minutes, and then cool to make a liquid medium.

[0052] Secondly, the preparation method of the broth seed liquid and Lactobacillus casei bacterium starter is the same as in Example 1, and will not be repeated here, the difference is that inoculating the liquid c...

Embodiment 3

[0066] Weigh 150 parts of soaked soybeans, 1650 parts of pure water, 72 parts of glucose, and 180 parts of skimmed milk powder, put the soaked soybeans and pure water in the soymilk machine, and the soymilk machine will mix the soaked soybeans and pure water to make pulp residue, and Add glucose and skim milk powder to the mixed pulp residue for deployment, then put the prepared mixed pulp residue into a homogenizer for homogenization, keep the pressure at 30MPa for 10 minutes, and after 10 minutes, homogenize The completed mixed pulp residue is placed at 105-121° C. for sterilization, sterilized for 40 minutes, and then cooled to make a liquid culture medium.

[0067] Secondly, the preparation method of broth seed liquid and Lactobacillus casei bacterium mother starter is identical with embodiment one, does not go into details here, and difference is: first inoculate the Bacillus subtilis that volume fraction is 5.5% in liquid culture medium, The number of live bacteria of Ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com