Linear-motion bearing with flange attached

A technology of linear motion bearings and flanges, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve the problems of high cost, achieve high adhesion, high joint strength, and improve the effect of joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

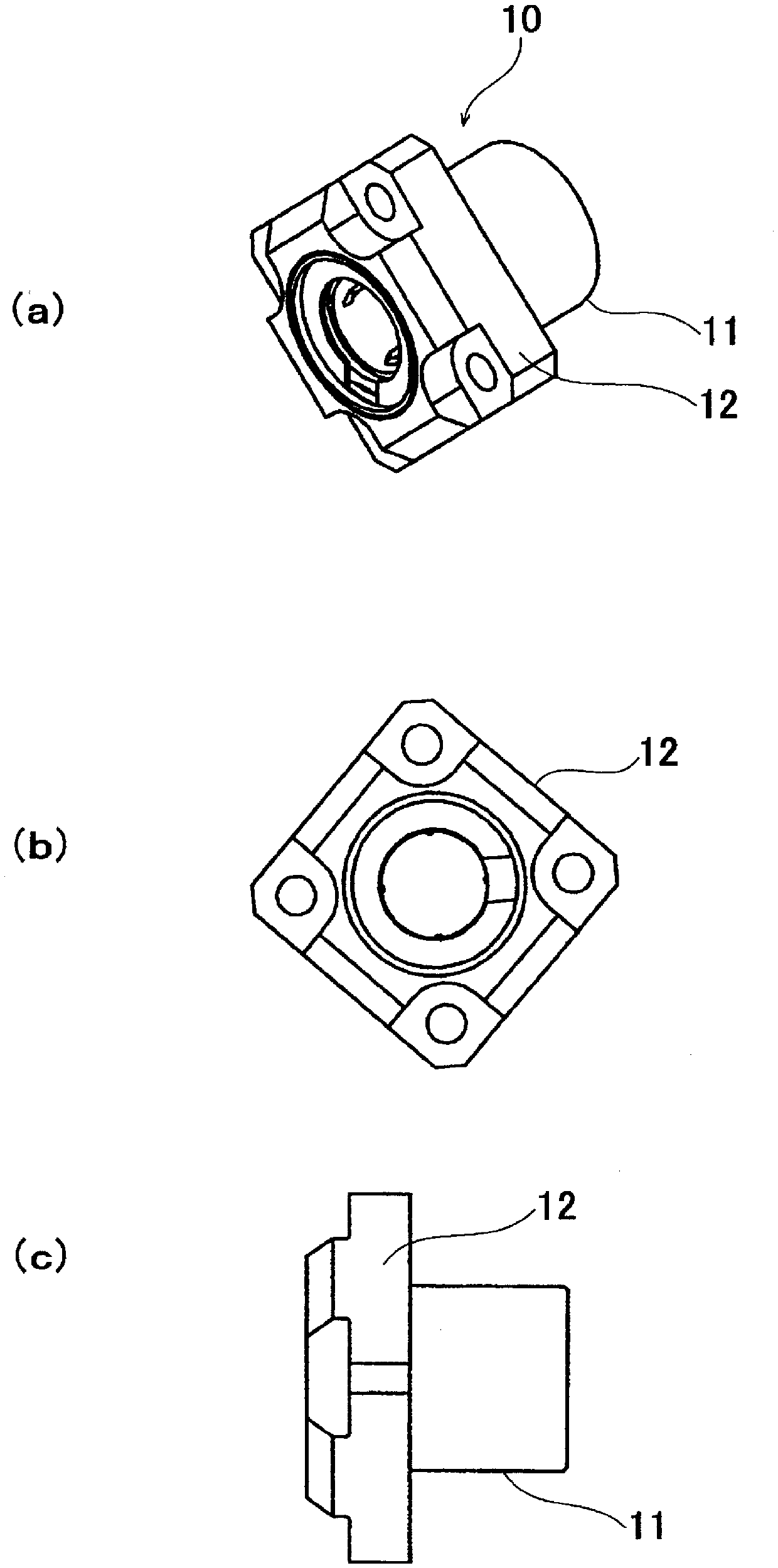

[0019] First, a representative embodiment of the flanged linear motion bearing of the present invention will be described with reference to the drawings.

[0020] in figure 1 Here, a perspective view (a), a bottom view (b), and a side view (c) of a configuration example of the flanged linear motion bearing 10 of the present invention are shown. in figure 1 In the shown flanged linear motion bearing 10, a ribbed flange 12 is formed on one end of the linear motion bearing 11. The linear motion bearing 11 may use a linear motion bearing having a general structure of a linear motion bearing, that is, it includes an outer cylinder, a cylindrical rolling element cage fitted inside the outer cylinder, and a cylindrical rolling element cage held in the cylindrical rolling element cage. Multiple rolling elements. As the linear motion bearing, an infinite loop type linear motion bearing and a non-infinite loop type linear motion bearing are known, and either of them can be used. In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com