Cap press-in apparatus

A press-in device and cap technology, which is applied in the direction of assembling battery machines, battery covers/end covers, electrical components, etc., can solve the problems of low assembly efficiency, high labor intensity, and difficult to guarantee product quality, so as to improve production efficiency and product quality. Reliability, simple power transmission, and the effect of saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

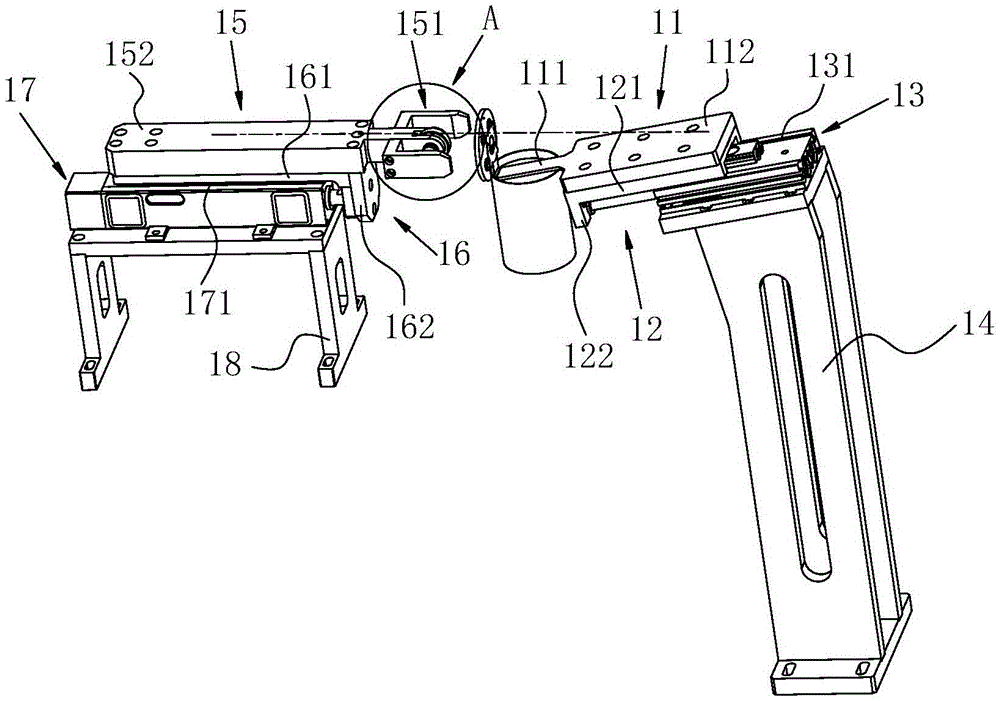

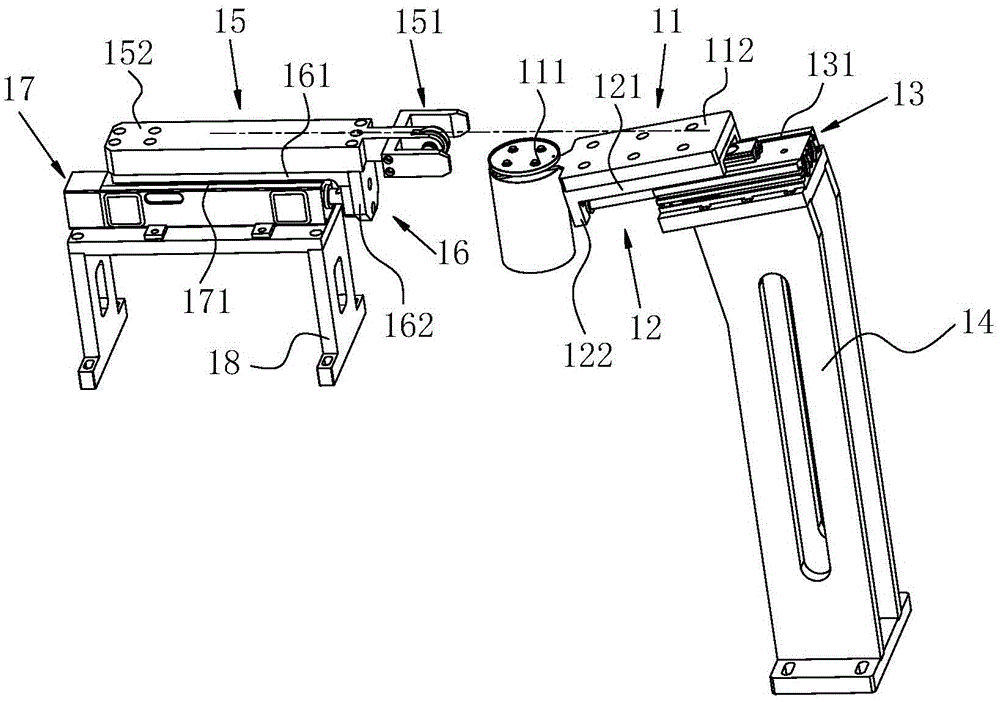

[0062] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

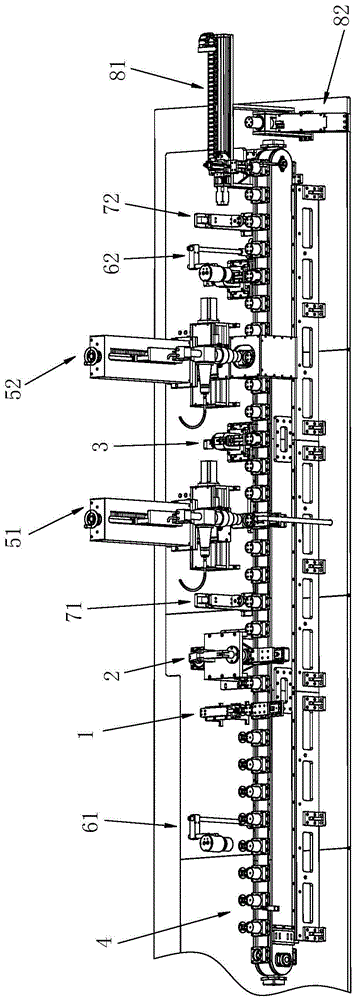

[0063] like Figure 1-8 As shown, in this embodiment, a battery forming system, such as figure 1 As shown, it includes a battery conveying line 4 for transferring batteries, and a current collector bending device 1, a cap pressing device 2, a first welding device 51, and a battery turning device 3 arranged in sequence along the feeding direction of the battery conveying line 4 , the second welding device 52 and the battery unloading manipulator 81, the end of the battery conveying line 4 corresponds to the battery unloading manipulator 81 is provided with a defective battery box 82, one side of the battery conveying line 4 is located between the cap pressing device 2 and the first A first short-circuit detection device 71 is fixedly installed between the welding devices 51, and a second short-circuit detection devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com