Sealed optical fiber connector

A technology of optical fiber connector and optical fiber, which is applied in the direction of light guide, optics, instruments, etc., can solve the problems of shell processing and assembly accuracy not meeting the requirements, large insertion loss of connectors, loss of floating function of contact pieces, etc., to ensure sealing performance, reduce insertion loss, and ensure the effect of signal transmission quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

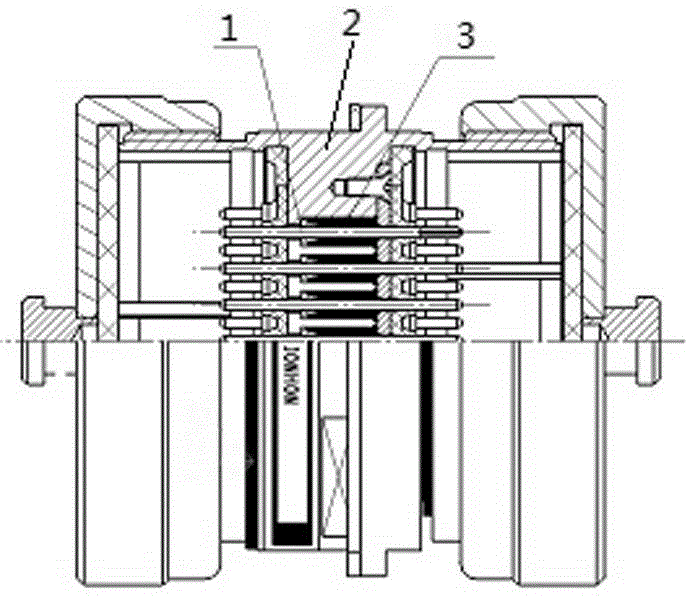

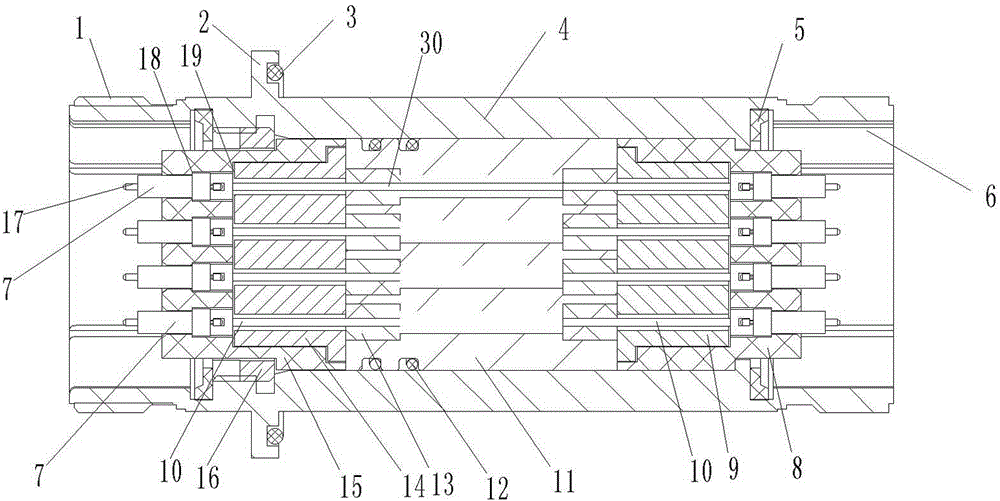

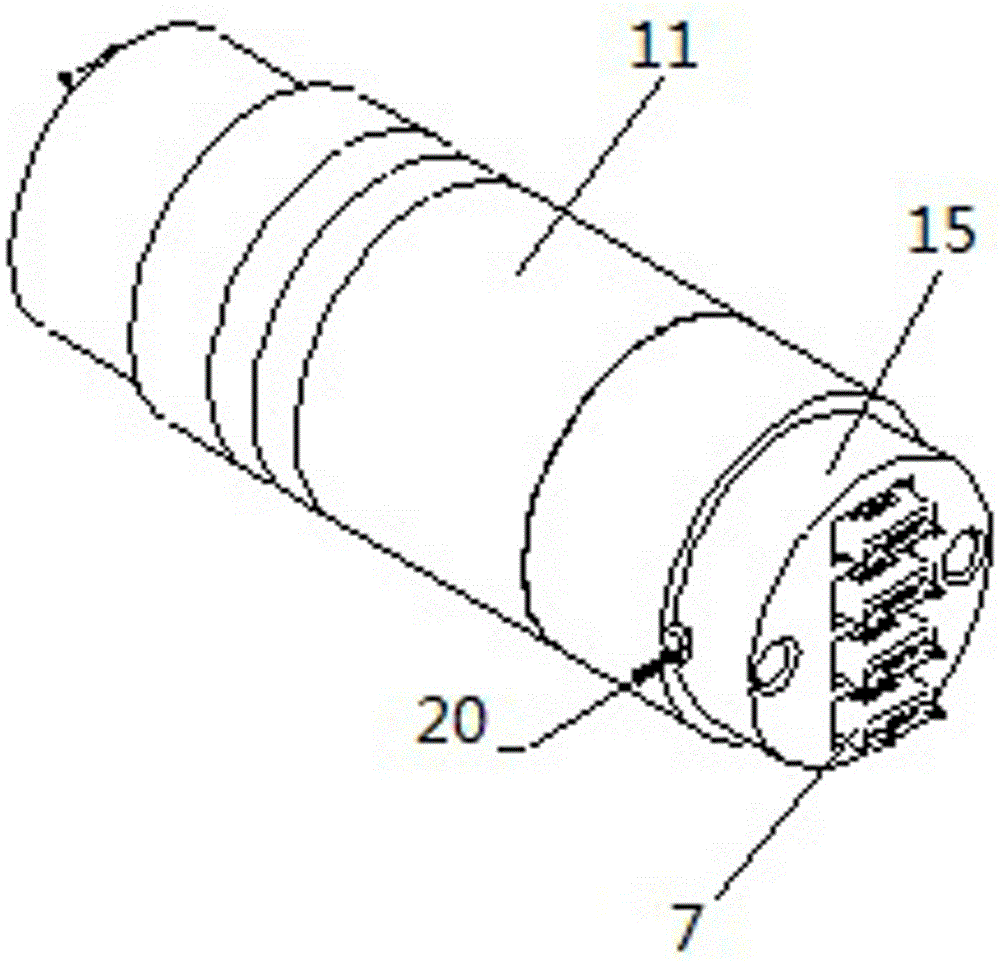

[0019] Examples of sealed fiber optic connectors are Figure 2~6 As shown: it includes optical contacts 17 and a housing. There are multiple optical contacts and are located at both ends of the housing. The optical contacts at each end are divided into four optical contact groups arranged at intervals along the up and down direction. Each optical contact Each component group includes 12 optical contacts. The optical contacts in each optical contact group are connected together through connectors to form an MT pin 7. The MT pin on the left and the MT pin on the right The pins are set in one-to-one correspondence, and the corresponding two MT pins are connected by optical fibers. The housing includes an outer housing 4 and an inner housing. The outer housing 4 is provided with a connecting flange 2 and a connecting structure for connecting with an adapter connector. The connecting structure includes external threads 1 and internal threads 6 arranged at both ends of the outer hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com