Oxygen sensor for internal combustion engine

A technology of oxygen sensor and internal combustion engine, applied in the field of oxygen sensor to achieve the effect of reliable electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, technical solution of the present invention will be further described:

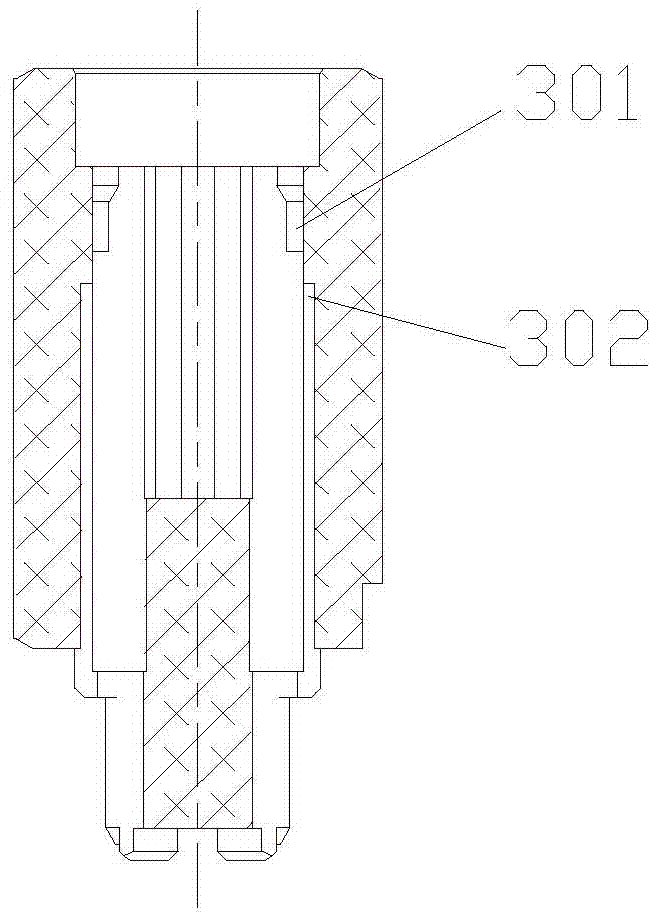

[0022] like Figure 1~5 As shown, the oxygen sensor for an internal combustion engine includes two contact springs 2, a ceramic bushing 3 and a heating rod 1, and the two contact springs 2 are symmetrically assembled into the ceramic bushing 3, and the heating rod 1 is pressed between the two contact springs. Both sides of the inner wall of the bushing 3 are symmetrically provided with an upper fixing structure 301 and a lower fixing structure 302 respectively. The upper fixing structure 201 of 2 is assembled with the upper fixing structure 301 of the ceramic bushing 3, the lower elastic structure 202 of the contact spring 2 is assembled and combined with the lower fixing structure 302 of the ceramic bushing 3 to form an undercut structure 205, and the undercut structure 205 It has the characteristics of easy assembly and difficult disassembly.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com