Cone calorimeter

A cone calorimeter and heat flux technology, applied in the field of measuring instruments, can solve problems such as single test parameters and inability to quantify test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described below in conjunction with accompanying drawing.

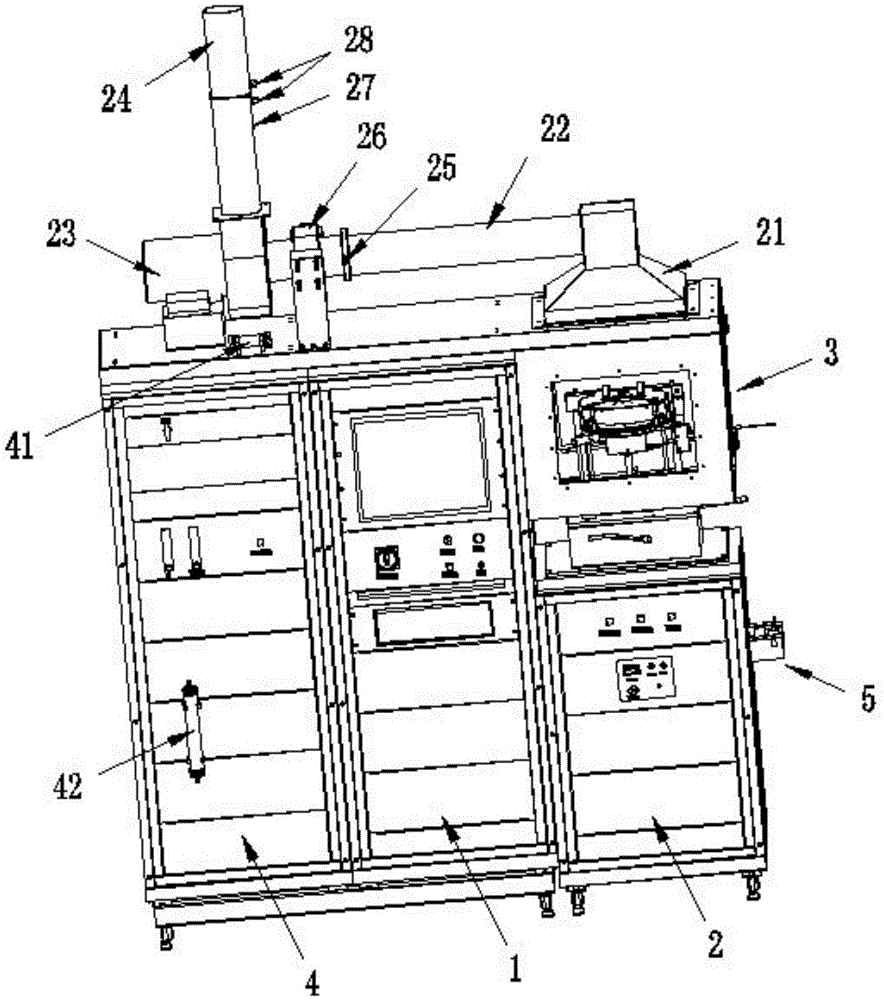

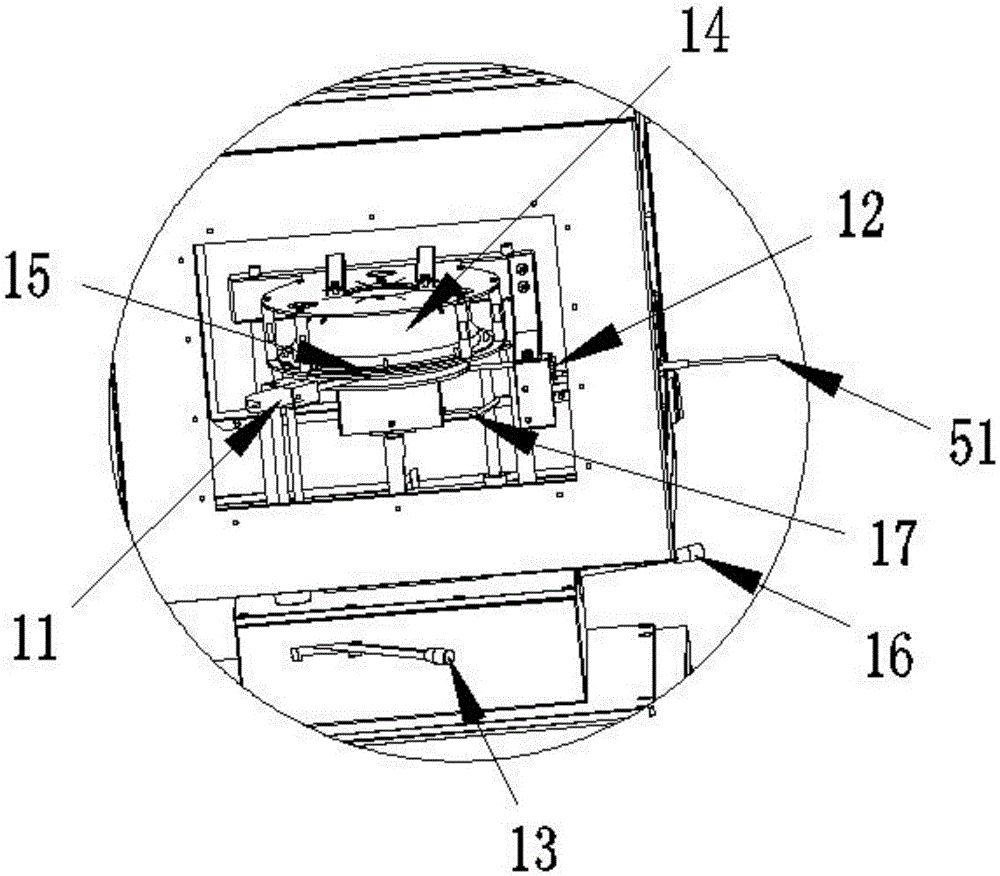

[0021] like figure 1 As shown, a cone calorimeter according to the present invention includes a main control machine 1, a secondary control machine 2, a combustion radiation device 3, a smoke exhaust assembly and a gas analysis device 4; the main control machine 1 controls each part Working and running, and receiving feedback signals, the main control machine 1 is provided with a display screen, the position of the main box and a plurality of control buttons, and the control buttons include a main control switch, a power switch, a speed control knob, and a fan switch and an emergency stop button; The sub-controller 2 controls the combustion radiation device 3, and the sub-controller 2 is also provided with a heat flux meter assembly 5 and its water cooling circulation system, and the combustion radiation device 3 is provided with a heat flux meter detection part; The device 3 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com