LED (light-emitting diode) point light source

A point light source, LED lamp bead technology, applied in the direction of light source, semiconductor devices of light-emitting elements, loss prevention measures of lighting devices, etc., can solve problems such as uncontrollable products and defects, achieve simple installation and production process, reduce bright spots, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

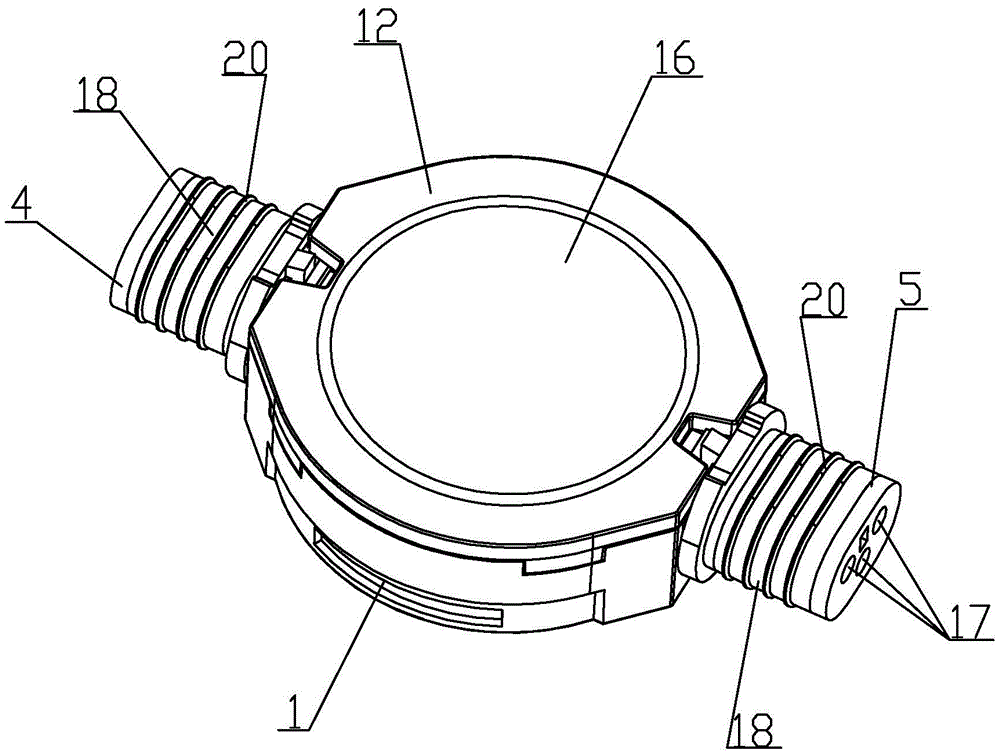

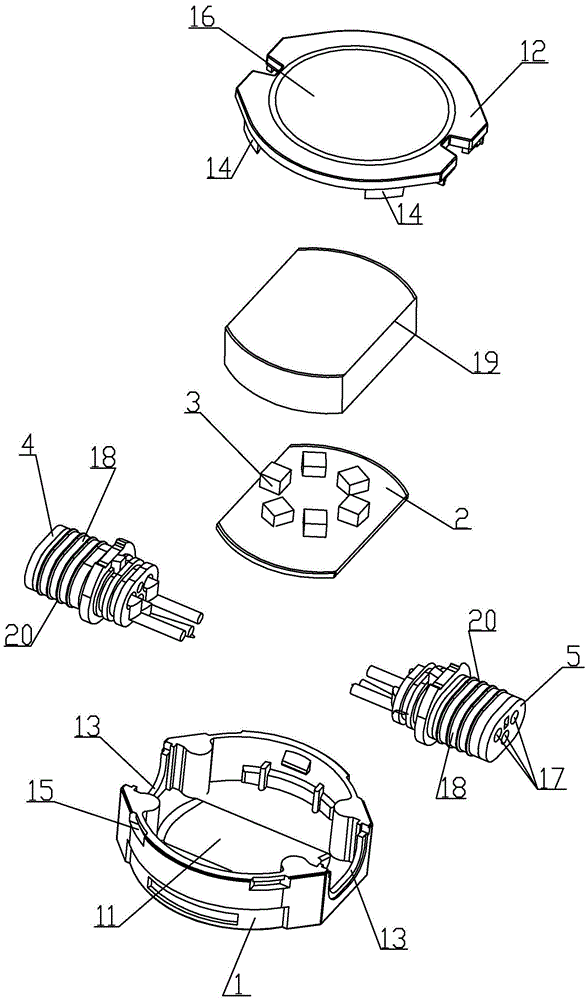

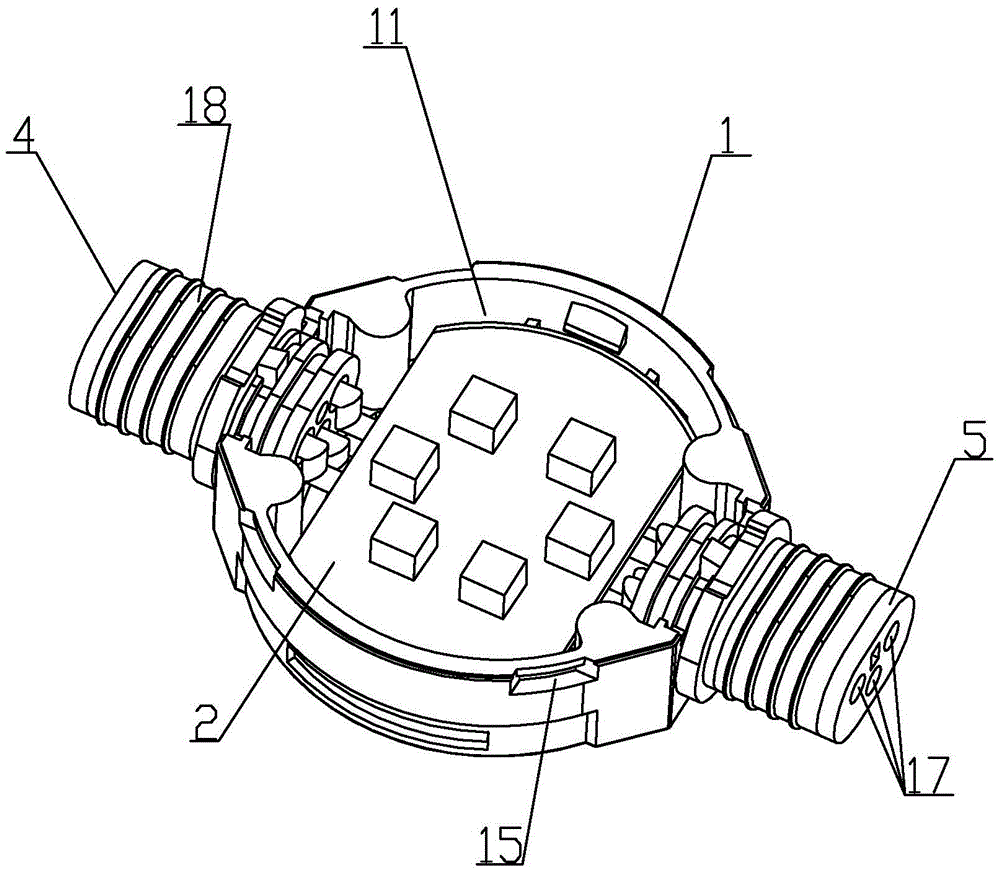

[0021] Such as Figure 1 to Figure 3 As shown, an LED point light source includes a casing 1, a circuit board 2 is arranged inside the casing 1, an LED lamp bead 3 is arranged on the circuit board 2, a concave cavity 11 is arranged inside the casing 1, and the circuit board 2 is arranged on Inside the concave cavity 11, the housing 1 is provided with a light-transmitting surface cover 12 that covers the opening of the concave cavity 11. The middle part of the light-transmitting surface cover 12 has an astigmatism protrusion 16, and the astigmatism protrusion 16 plays a role in astigmatism, preventing the The brightness is different, and the shape of the transparent surface cover 12 on the shell 1 is similar to a cake shape. In order to fix the circuit board 2 firmly, the glue filling process can be used. Inner transparent glue injection layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com