Steplessly adjustable speed diesel engine-centrifugal pump combination

A diesel engine and centrifugal pump technology, applied in engine control, machine/engine, liquid fuel engine, etc., can solve the problems of inability to accurately adjust the speed change, inability to achieve stepless speed regulation, and unstable diesel engine adjustment process, etc. Achieve the effect of solving the jumping change of speed, accurate speed and improving maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

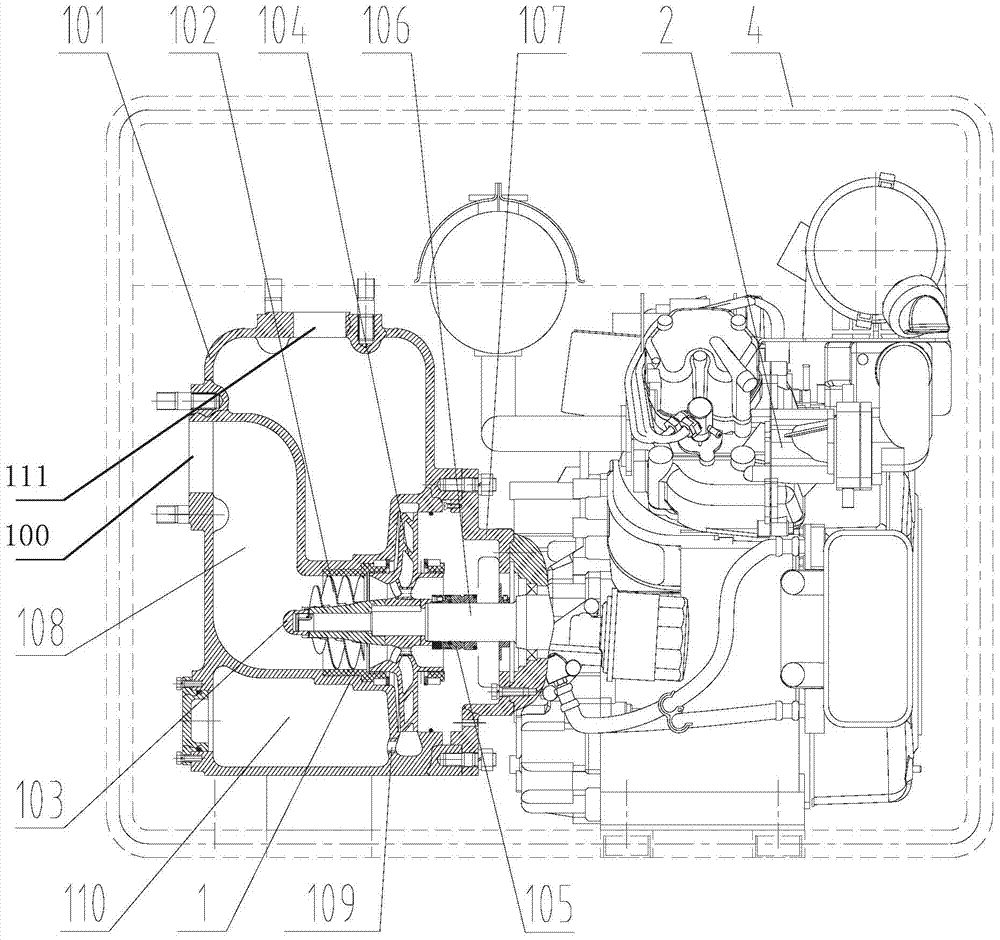

[0033] See figure 1 The casing 101 of the centrifugal pump of the pump set of the present invention is equipped with an inducer 102, an impeller 104, and a mechanical seal 105; the fluid enters the water inlet 100 of the casing 101 and then passes through the inducer 102, the impeller 104, and then the The water outlet 111 flows out; the inducer 102 and the impeller 104 are driven with the main shaft through a key; one end of the main shaft 106 is the power input end, which is fastened to the crankshaft of the diesel engine with a connecting screw through the extension shaft structure; the other end of the main shaft is connected to the inducer 102, The impeller 104 and the mechanical seal 105 are fixedly connected, and the inducer is located at the front end of the impeller. A shaft head lock nut 103 is provided at the other end of the main shaft, and the shaft head lock nut is used to axially fix the inducer and the impeller. During installation, the position of the impeller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com