Valve mechanism system with hydraulic lash adjuster and exhaust brake

A lash adjuster, exhaust valve technology, applied in the direction of machine/engine, engine components, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

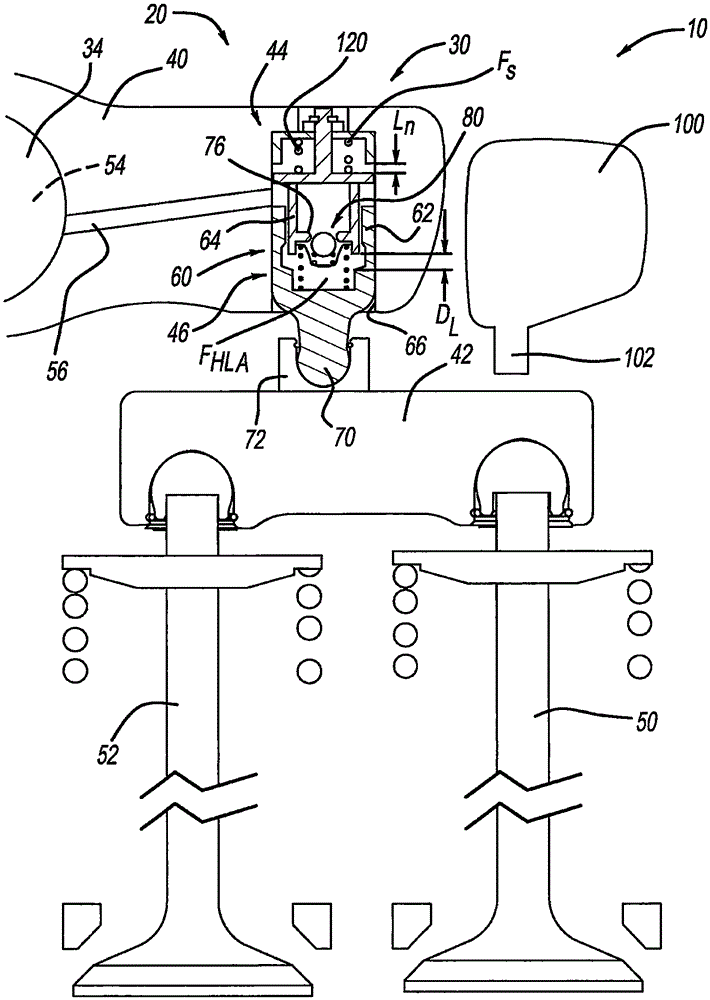

[0020] First refer to figure 1 , a portion of a valvetrain assembly constructed in accordance with an example of the present invention is shown and generally designated by the reference numeral 10 . Portions of the valvetrain assembly 10 use engine braking. Portion of valvetrain assembly 10 may include rocker arm assembly 20 having a series of intake rocker arm assemblies (not specifically shown) and a series of exhaust valve rocker arm assemblies 30 . Rocker shaft 34 is received by a rocker housing (not specifically shown). As will be understood from the discussion below, rocker shaft 34 cooperates with rocker assembly 20 and, more specifically, exhaust valve rocker assembly 30 to communicate oil to exhaust valve rocker assembly 30 during engine braking.

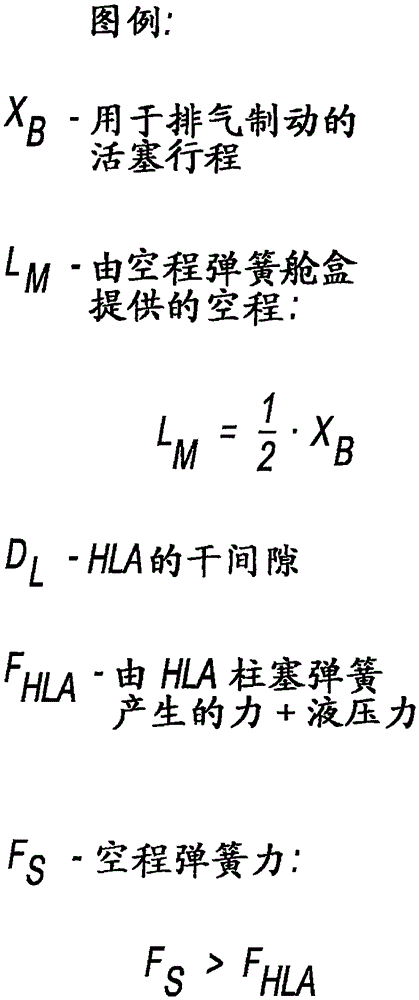

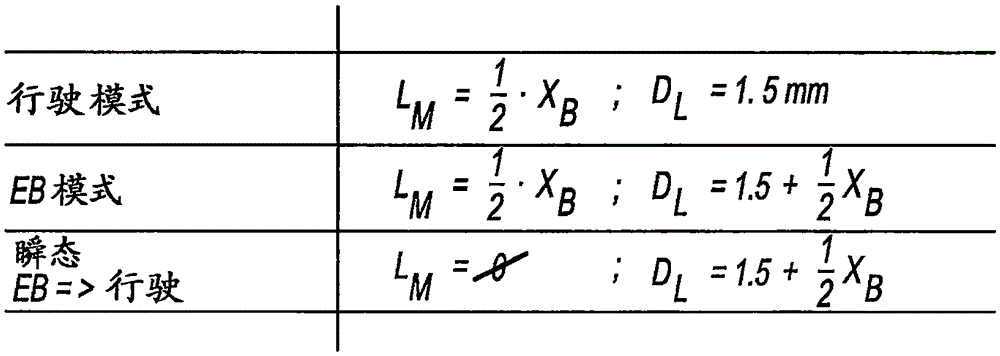

[0021] Now generally refer to Figure 1-5 Exhaust valve rocker arm assembly 30 may generally include a rocker arm 40 , a valve bridge 42 , an elastic pod 44 , and a hydraulic lash adjuster (HLA) assembly 46 . The valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com