Device for leveling super-flat floor and method for conducting super-flat floor construction through device

A construction method and floor technology, applied in the processing of building materials, construction, building structure, etc., can solve problems such as large deviation of floor flatness, inability to meet ultra-flat floors, affecting construction progress, etc., and achieve convenient production, Avoid cumbersome process construction and improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

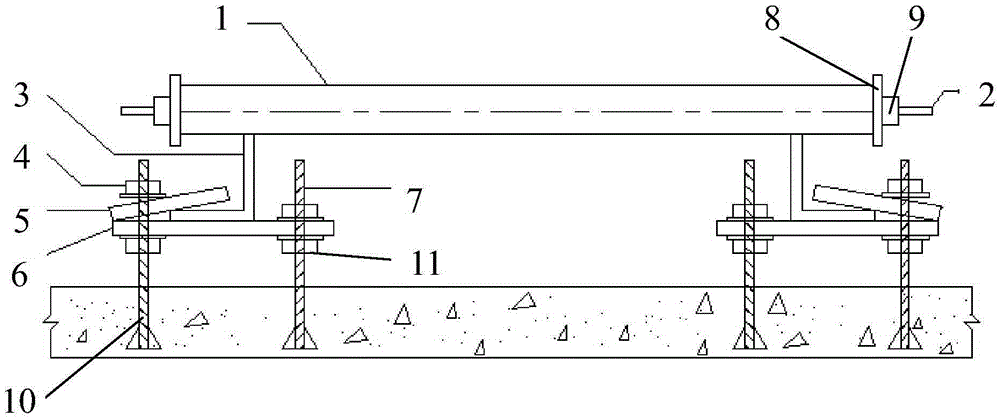

[0029] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

[0030] The leveling device of the present invention is arranged on the concrete cushion of an ultra-flat floor, and the concrete cushion is divided into a plurality of strip-shaped areas by means of elastic lines. In an embodiment of the present invention, the width of each strip-shaped area is 4 meters. On the concrete cushion, the construction of the floor is strictly carried out according to the strip area division. The construction can be started from one side of the concrete cushion, or it can be started from both sides at the same time.

[0031] like figure 1 As shown, the device includes: a prestressed scraper, an angle steel 3, a backing plate 6, a pressing plate 5 and a plurality of pairs of height-adjustable bolts. On both sides of each strip area, at an interval of 1.5-2.0m, such as 2m, a pair of spaced holes are respectively arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com