Supporting joist for building

A technology for building and section steel, which is applied in construction, building structure, and on-site preparation of building components, can solve problems such as unreasonable structure, self-weight, poor strength, stiffness and other mechanical properties, and reduce production costs. , The effect of light weight and reduced structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

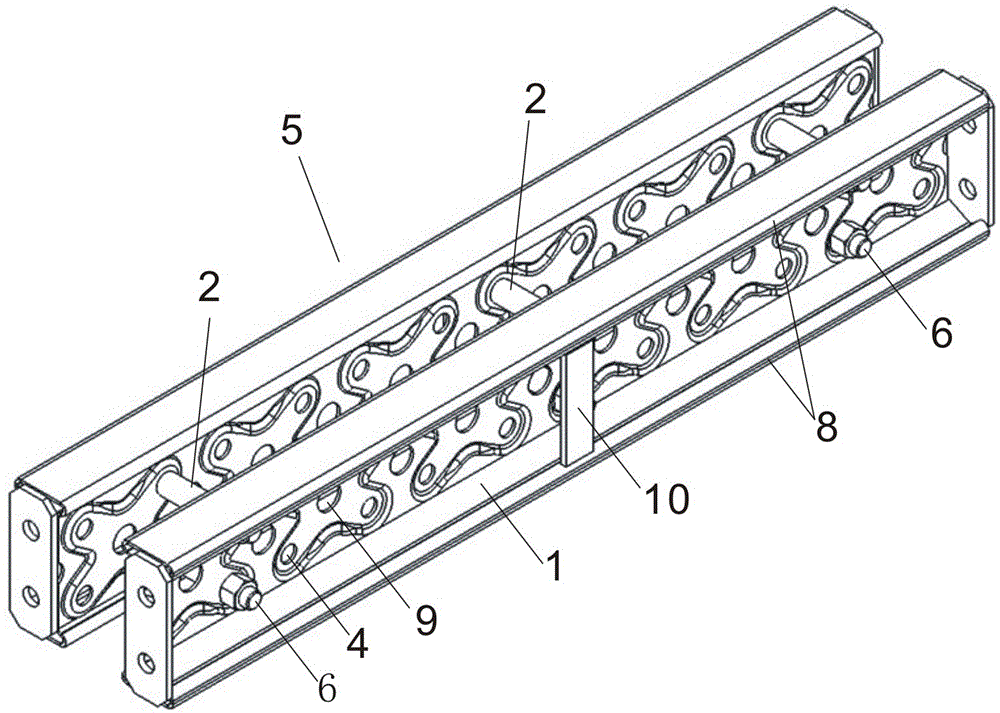

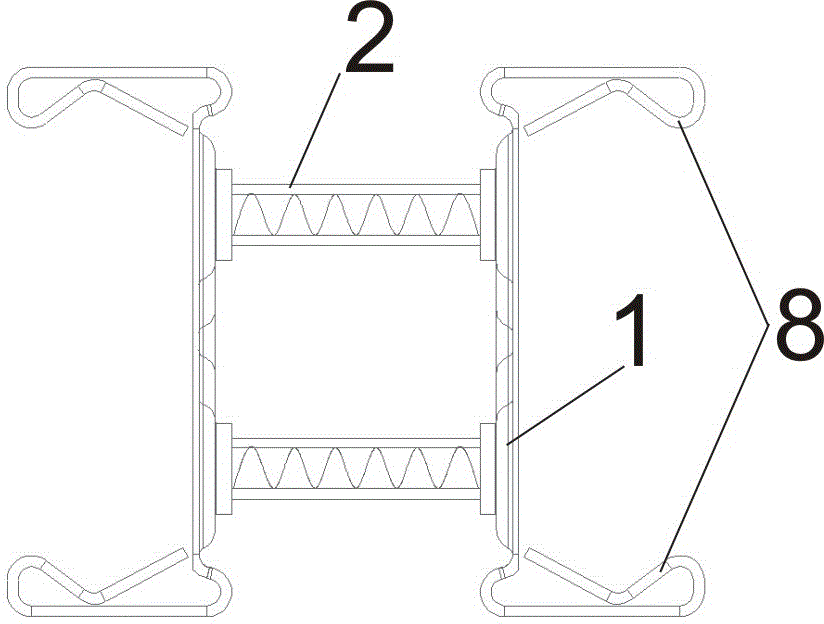

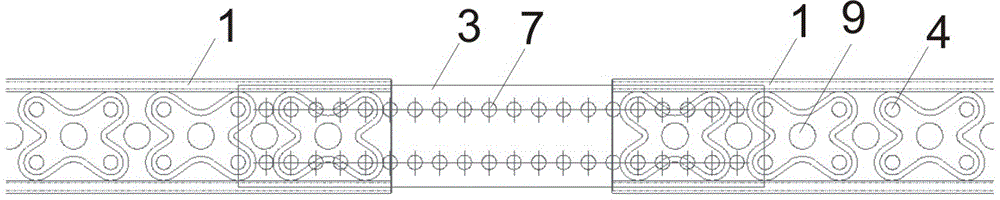

[0016] Embodiment: The U-shaped steel 1 of the present invention is made of Q345 material, and the strength is significantly improved. The U-shaped steel 1 is a cold-formed thin-walled structure, which is processed by a forming process, and the mold is cold-formed, which embodies the characteristics of light weight and high strength of steel; The upper and lower flanges 8 of the U-shaped steel 1 are curled inwardly, and a row of punched connecting holes 4 are arranged on the upper and lower sides of the web of the U-shaped steel 1, and a row of connecting holes 4 is arranged between the upper and lower connecting holes 4. The heavy round hole 9, the opening reduces the weight while ensuring the strength, reduces the consumables, and reduces the cost, while the round hole is to prevent stress concentration; in order to improve the local stability of the flange, on the U-shaped steel 1, Reinforcement plates 10 are arranged at equal intervals between the lower flanges 8; the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com