Assembly for connecting ridge covering cap with roof panels

A technology of roof panels and caps, which is applied to roofs, roofs, and roof coverings using flat/curved panels, and can solve problems such as detachment, roof ridge leakage, and roof panel deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

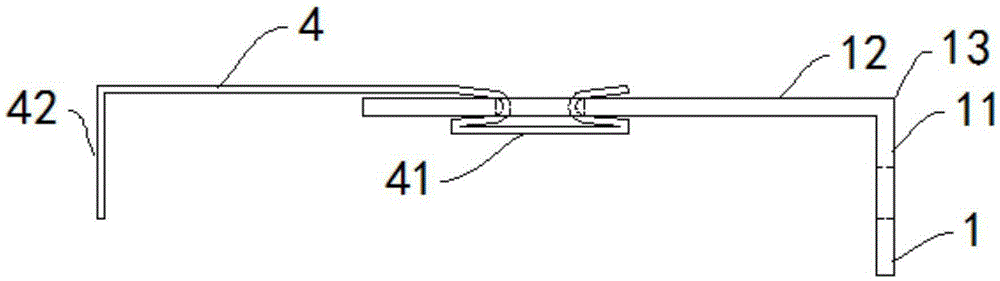

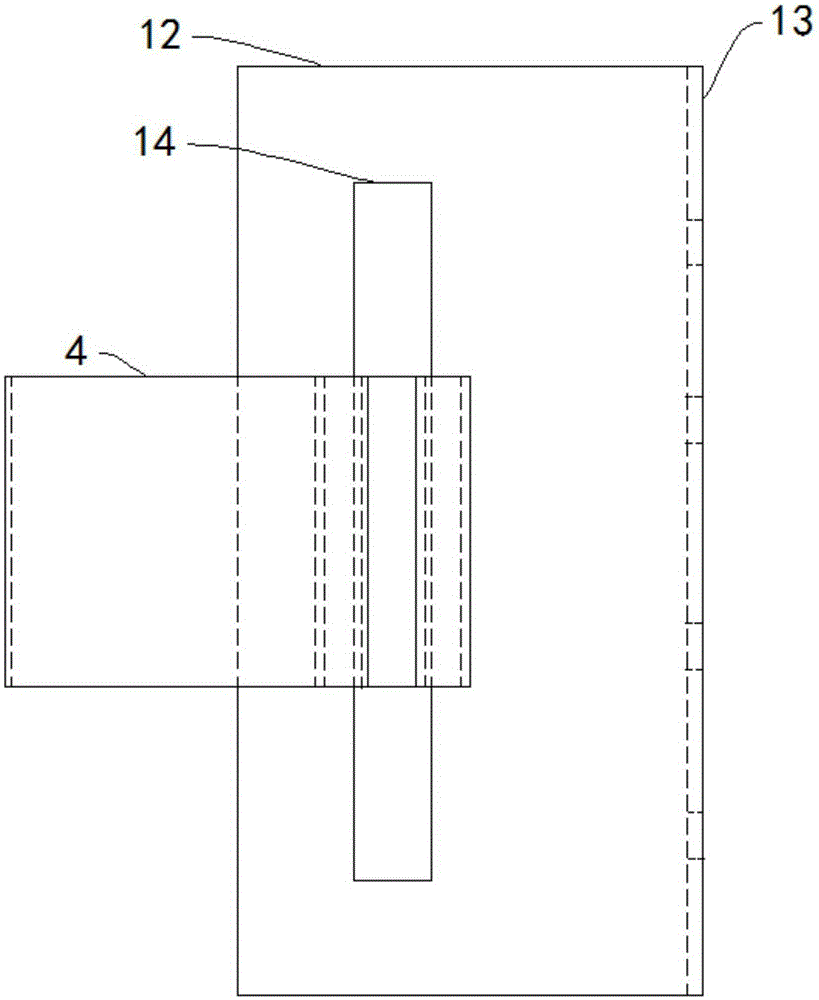

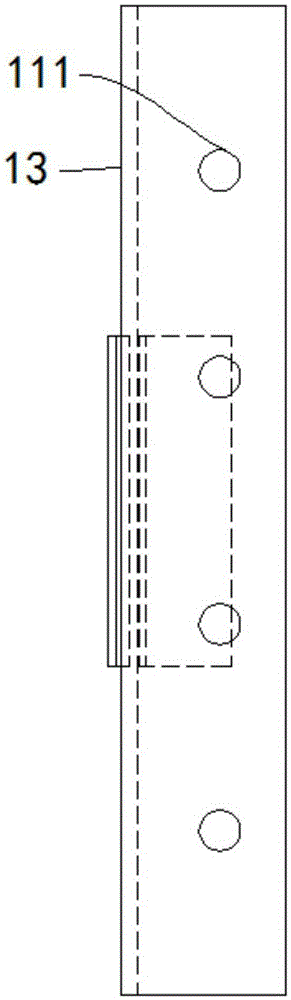

[0030] Such as Figure 1 to Figure 5 As shown, a component for connecting a roof ridge cap and a roof panel includes a right-angle bracket base 1. The first right-angle panel 11 of the right-angle bracket base 1 matches the shape of the seam 21 of the roof panel 2 and is used for The locking edge 21 is fixedly connected, and the second right-angle panel 12 of the right-angle bracket base 1 is provided with a sliding member 4 that can move parallel to the corner edge 13 of the right-angle bracket base 1 for fixed connection with the ridge cap 3. The sliding member 4 is fixedly connected to the roof ridge cap 3 by self-tapping screws.

[0031] Due to the long single slope length of the steel structure metal roof, the roof panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com