Method and device for water filling and pressure balance of extra-high-head gate

A high water head and gate technology, applied in water conservancy projects, hydropower, hydropower stations, etc., can solve the problems of inability to open the working valve, difficult handling, gate vibration, etc., to reduce the amount of dirt entering the water intake, which is conducive to safety. , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

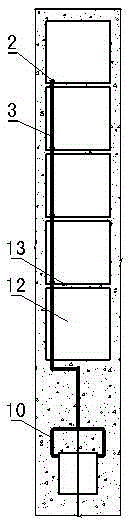

[0032] The method in this example is as Figure 1-5 As shown, during specific implementation, four layers of bypass pipelines 2 are arranged from top to bottom in the drainage structure 1 to converge to a main pipe 3 and then lead to the upper part of the drainage tunnel between the emergency gate 4 and the arc gate 5 On the side wall 6, and in the section from the entrance of each bypass pipeline 2 to the main pipe section along the water flow direction, set up the sewage and water intake device 7, the maintenance valve 8 and the working valve 9 in sequence. After the main pipe 3 leads to the upper part of the discharge tunnel chamber, it is divided into a Two branch pipes 10 of line symmetry. The topmost bypass pipeline is lower than the normal water storage level and completely submerged in the normal water storage level elevation water, and the bottommost bypass pipeline is lower than the dead water level and completely submerged in the dead water level elevation water. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com