Light electric trolley for crane

A technology of electric trolleys and cranes, which is applied in the direction of load-bearing blocks, spring mechanisms, load suspension components, etc., which can solve the problems of increased self-weight of the trolley frame, troublesome installation and adjustment, and loose overall structure, etc., and achieve the improvement of carrying capacity , easy maintenance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

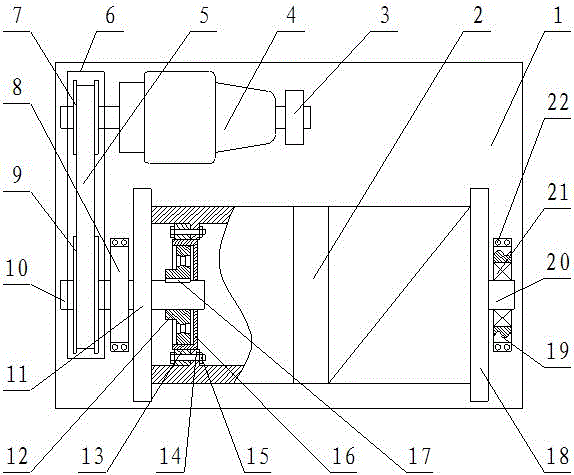

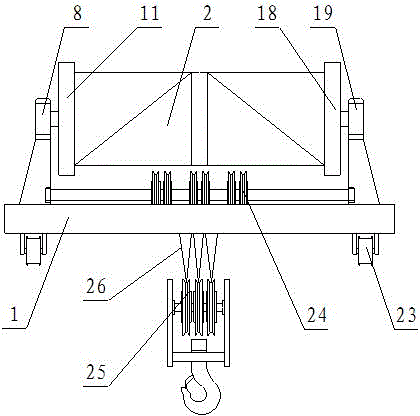

[0017] like figure 1 and figure 2 As shown in the figure, a portable electric trolley for a crane includes a trolley frame 1, the upper surface of the trolley frame 1 is provided with a roller 2, and the two ends of the roller 2 are respectively provided with a left end cover 11 and a right end cover Cover 18, the center of the left end cover 11 and the right end cover 18 are respectively provided with a support shaft A10 and a support shaft B20, the support shaft A10 and the support shaft B20 are respectively arranged on the left support 8 and the right support 19, The left support 8 and the right support 19 are arranged on the upper surface of the trolley 1, and the support shaft A10 is provided with a large synchronous toothed pulley 9, and the large synchronous toothed pulley 9 passes through. The toothed belt 5 is connected with a small synchronous toothed pulley 7, the small synchronous toothed pulley 7 is arranged on the output shaft of the motor 4, the brake 3 is con...

Embodiment 2

[0020] like figure 1 and figure 2 As shown in the figure, a portable electric trolley for a crane includes a trolley frame 1, the upper surface of the trolley frame 1 is provided with a roller 2, and the two ends of the roller 2 are respectively provided with a left end cover 11 and a right end cover Cover 18, the center of the left end cover 11 and the right end cover 18 are respectively provided with a support shaft A10 and a support shaft B20, the support shaft A10 and the support shaft B20 are respectively arranged on the left support 8 and the right support 19, The left support 8 and the right support 19 are arranged on the upper surface of the trolley 1, and the support shaft A10 is provided with a large synchronous toothed pulley 9, and the large synchronous toothed pulley 9 passes through. The toothed belt 5 is connected with a small synchronous toothed pulley 7, the small synchronous toothed pulley 7 is arranged on the output shaft of the motor 4, the brake 3 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com