Medicine production line

A production line and pharmaceutical technology, applied in packaging and other directions, can solve problems such as unreasonable structure, large space, and high noise, and achieve the effect of compact structure, low noise, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

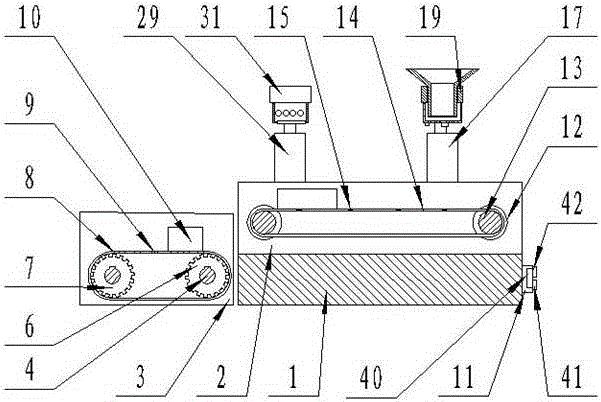

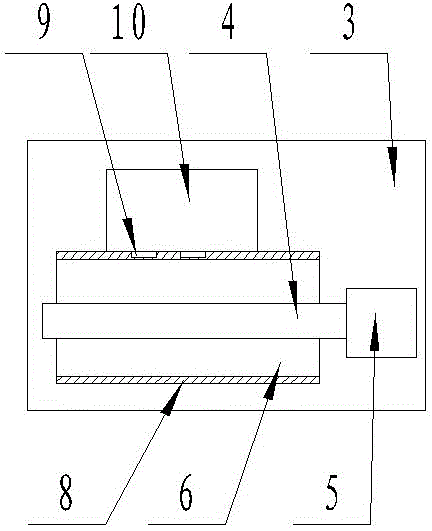

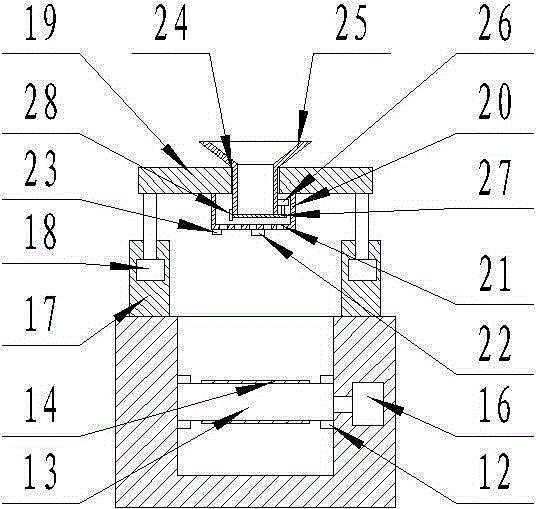

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a pharmaceutical production line includes a base (1), the upper surface of the base (1) is provided with a through groove (2) along its length, and a transmission mechanism is arranged inside the through groove (2). The upper surface of the base (1) is sequentially provided with a drug placement mechanism, a hot-press sealing mechanism, and a drug collection device along its length direction. The drug collection device consists of an installation frame located at one end of the transmission mechanism and fixed on the ground ( 3), the rotating shaft (4) located at the left and right ends of the installation frame (3), the motor B (5) which is fixedly installed on the outer surface of one end of the installation frame (3) and the rotating end is fixedly connected to one of the rotating shafts (4) , the driving wheel (6) fixedly set on the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com