Movable welding platform used for transverse and longitudinal joints of guiding pipe pile

A movable platform, horizontal and vertical seam technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing structural manufacturing cost, large volume, weight, inconvenient use, etc., and achieve reasonable structural design. , The effect of high safety performance and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

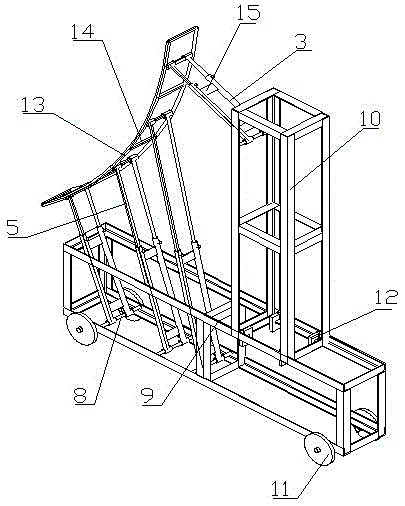

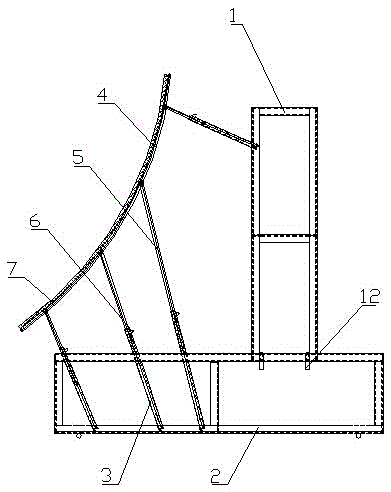

[0019] Such as figure 1 with figure 2 As shown, the invention discloses a movable platform for transverse and longitudinal seam welding of conduit piles, which includes a pair of vertical and parallel support frames, a working platform erected on the support frames and a ladder connected to the support frames.

[0020] The support frame includes a pair of steel pipes A1 arranged in parallel at the lower end, a pair of steel pipes B3 fitted on the upper part of the steel pipe A1 and fixed with a movable pin A, and a strengthening device arranged between the steel pipe A1 and the steel pipe B3; the upper end of the steel pipe A1 along the axial direction Set a number of through holes A2 horizontally passing through the opposite side walls of the steel pipe A1; set a number of through holes B4 horizontally passing through the opposite side walls of the steel pipe B3 along the axial direction at the lower end of the steel pipe B3, and the through holes B4 and the through holes A2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com