Liquid metal granulating system by adopting full-automatic program control dry process and method of liquid metal granulating system

A liquid metal, dry granulation technology, applied in the field of metal granulation, can solve the problems of violent explosion, personal hazards of equipment and property, and impact on the living environment, and achieve the effect of high metal utilization rate, good product quality and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

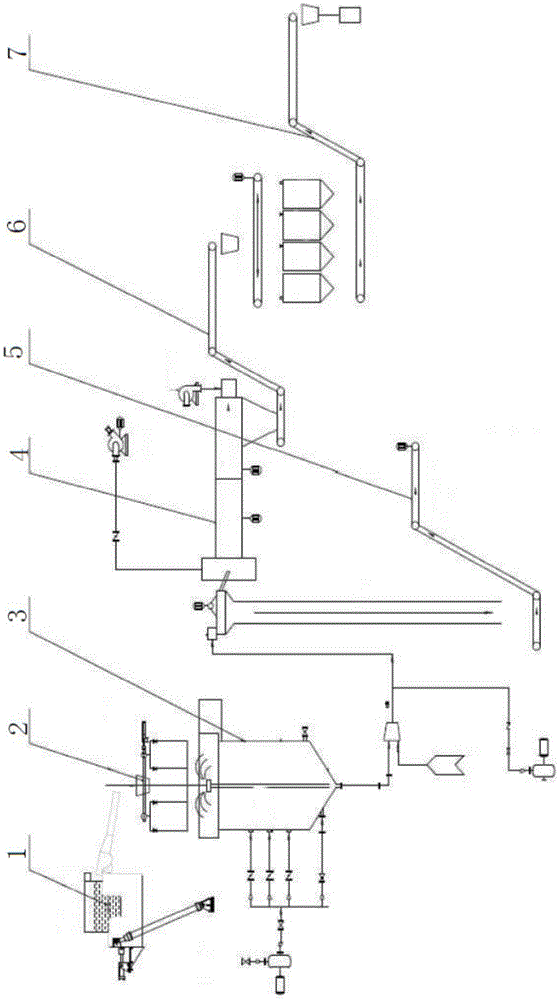

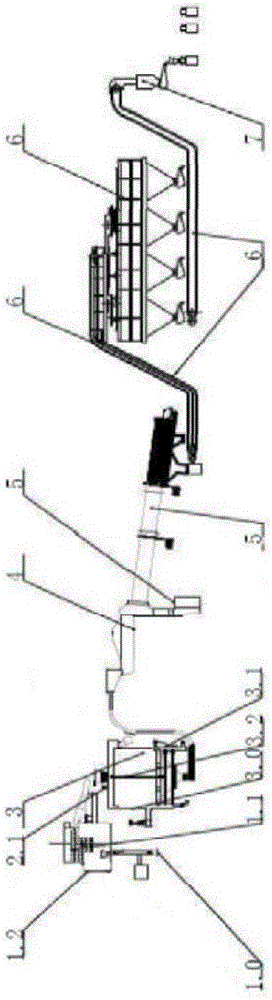

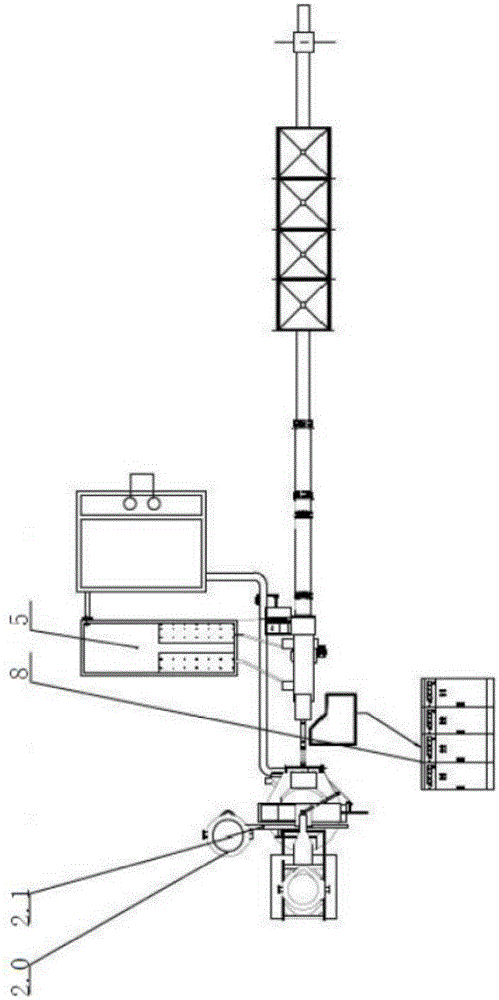

[0026] According to the accompanying drawings, a fully automatic program-controlled dry method liquid metal granulation system includes an automatic liquid supply system 1, an intermediate liquid supply overflow system 2, an automatic dry granulation system 3, and automatic dehydration and screening for finished product drying Drying system 4, automatic magnetic chip removal system 5, automatic conveying and storage system 6, finished product automatic bagging system 7 and control cabinet 8, the automatic liquid supply system 1 includes automatic hydraulic system 1.0, molten steel tank 1.1 and liquid supply rack 1.2, the intermediate liquid supply overflow system 2 includes an overflow tank 2.0 and an overflow tank 2.1, and the automatic dry granulation system 3 includes a dry granulation tank 3.0, an automatic air supply device 3.1 and a high-pressure air spray gun 3.2 , the molten steel tank 1.1 is rotationally matched with the liquid supply frame 1.2, the automatic hydraulic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap