Microwave-chip wax injection machine

A technology of microwave chip and wax injection machine, which is applied in the direction of casting and molding equipment, can solve the problems of heavy weight, large volume, low precision, etc., and achieve the effect of smooth and complete wax injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments.

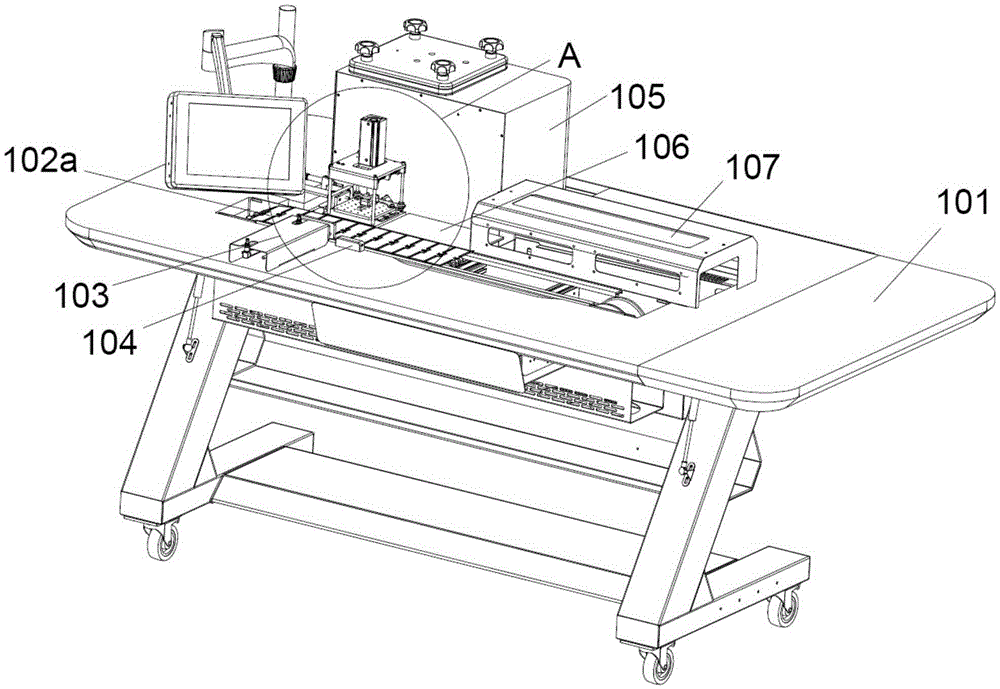

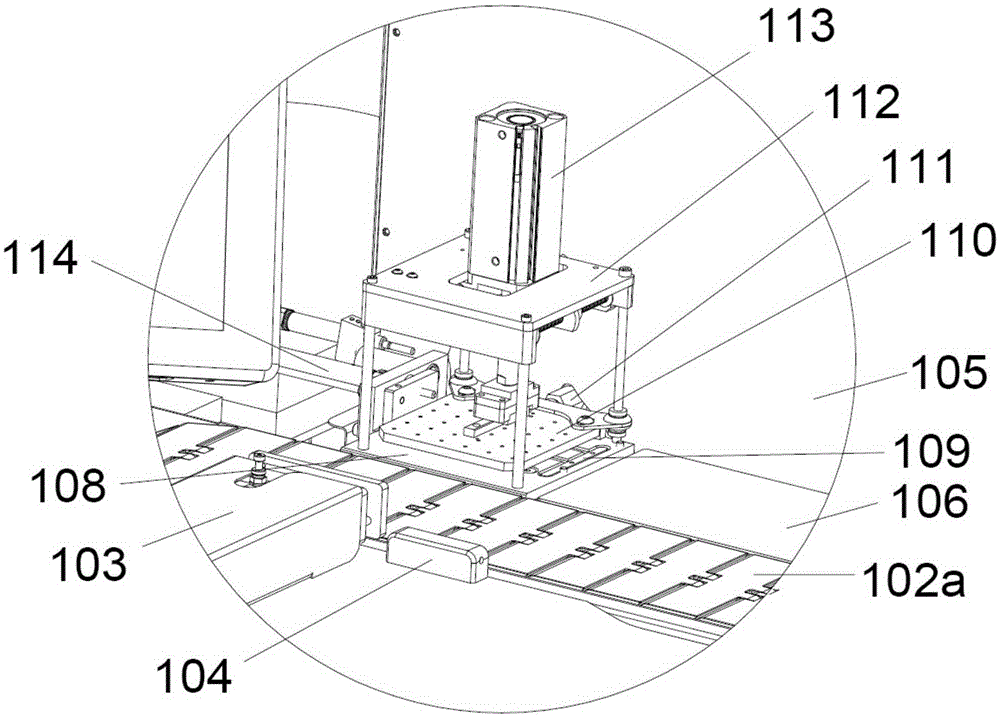

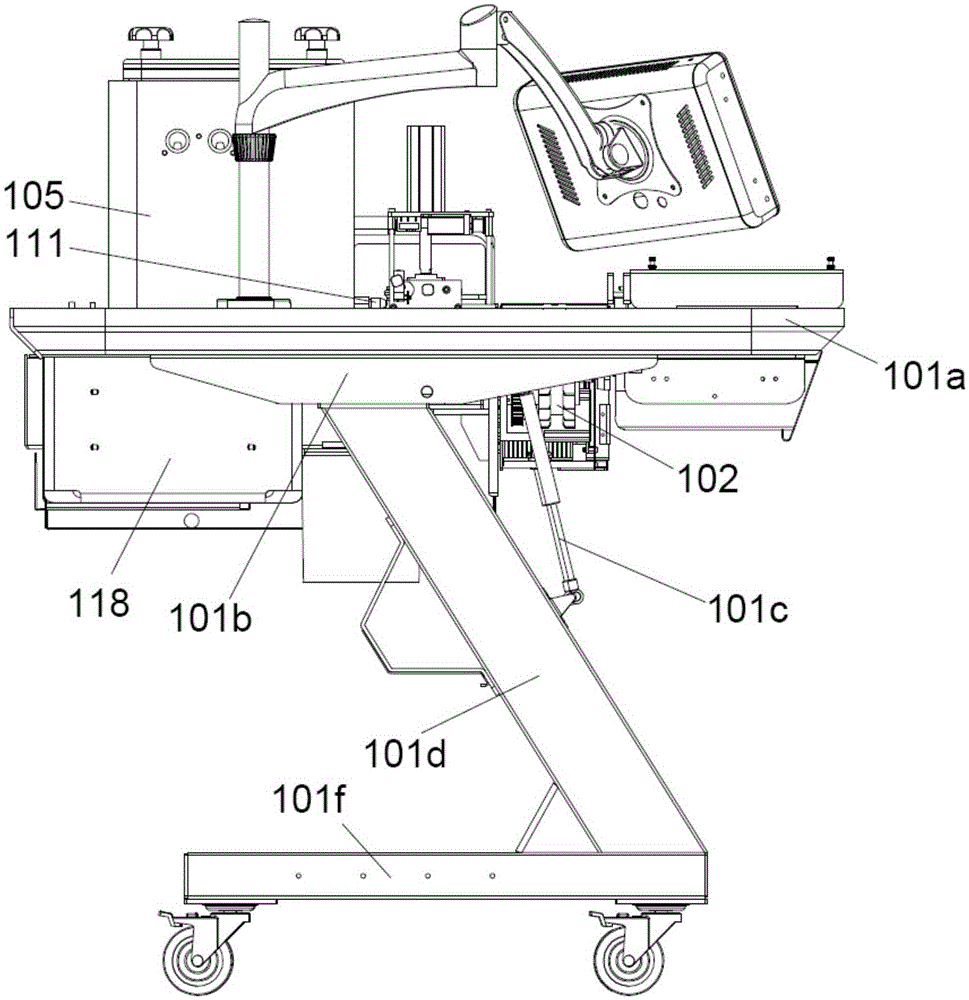

[0023] refer to Figure 1-5 , a microwave chip wax injection machine of the present invention includes a workbench 101 and a chain plate transmission mechanism 102 embedded in the workbench 101. The chain plate transmission mechanism 102 includes a transmission chain plate 102a for transporting wax injection molds. One side of the chain plate 102a is provided with a feeding push arm 103 and a mold detection sensor 104, and the other side of the conveying chain plate is provided with a mold positioning platform 108, and both sides of the mold positioning platform 108 are respectively provided with synchronously telescopic synchronous clamping blocks 109 The top of the mold positioning platform 108 is provided with a lower platen 110 moving up and down, and the opposite side of the conveyor chain plate of the mold positioning platform 108 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com