Machine head device of claw cutter

A technology of claw cutting machine and machine head, which is applied in the direction of metal processing, etc., can solve the problems of increasing maintenance rate, reducing production efficiency, increasing production cost, etc., and achieves the effects of improving production efficiency, reducing use and maintenance costs, and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

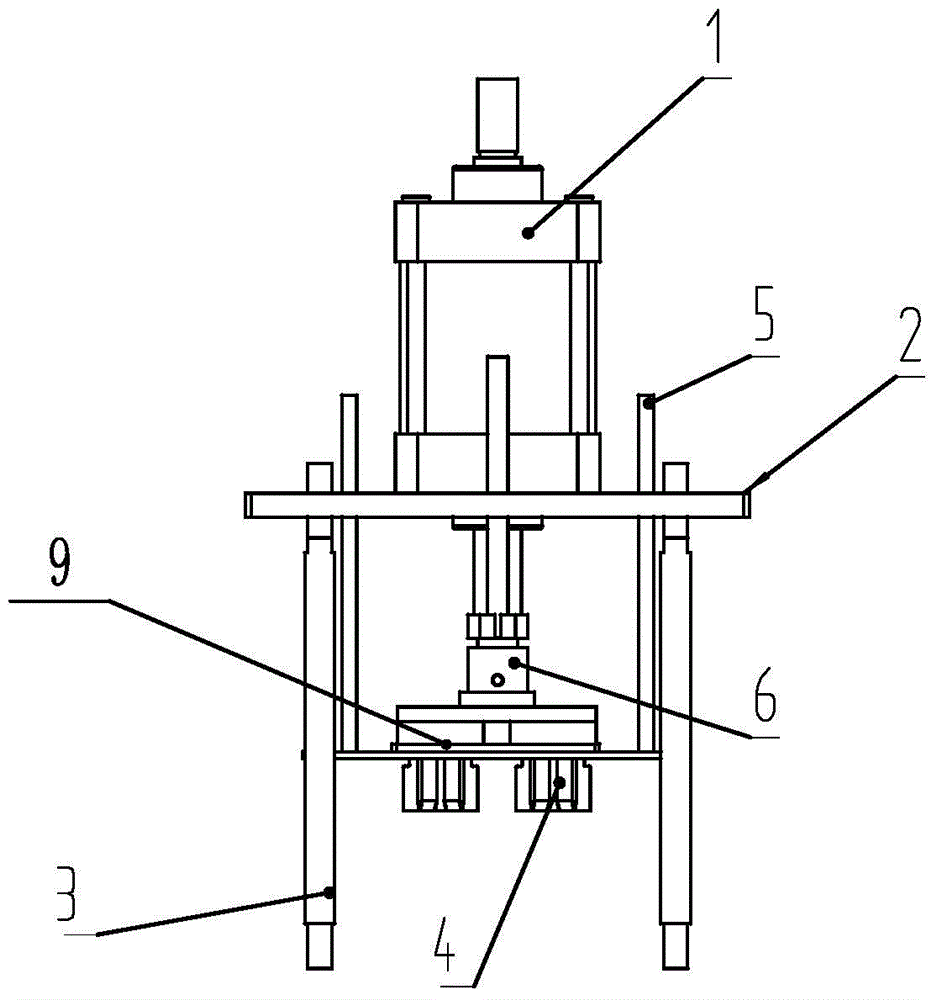

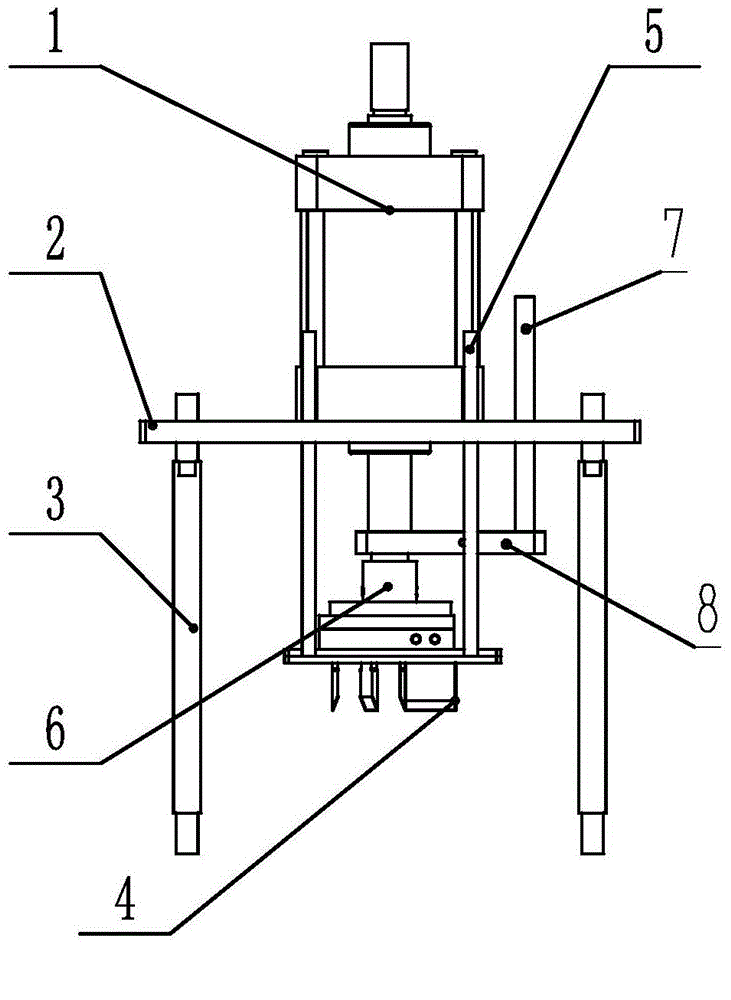

[0010] like figure 1 , 2 As shown, the present invention comprises cylinder 1, frame plate 2, support rod 3, cutter 4, guide rod 5, cutter holder sleeve 6, limit rod 7, limit connection lock plate 8, cutter holder 9, described The upper side of the frame plate 2 is provided with a cylinder 1, the four corners of the frame plate 2 are respectively provided with support rods 3, the lower side of the cylinder 1 is provided with a cutter frame 9, and the cutter frame 9 is connected to the cylinder by the cutter frame sleeve 6. 1 connection, the four corners of the cutter frame 9 are provided with guide rods 5, the guide rods 5 penetrate the frame plate 2 upwards, and the limit connection lock plate 8 is provided above the cutter frame sleeve 6, and the limit connection lock plate 8 is fitted on the lower side of the cylinder 1, the other end of the limit connecting plate is fitted and fixed with the limit rod 7, the limit rod 7 penetrates the frame plate 2 upward, and the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com