A molding die for round tube type automobile anti-collision bar

A technology of automobile anti-collision bars and pressure molding dies, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that it is difficult to meet large batch production capacity, uneconomical forming process methods, and increase production costs. Mass production requirements, eliminating time-consuming and labor-intensive effects, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

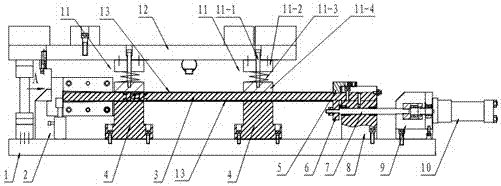

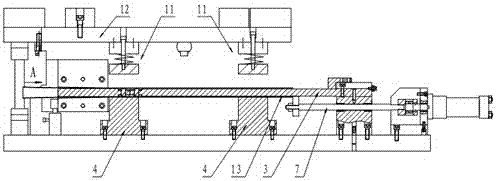

[0025] See figure 1 , figure 2 , The pressing die of the present invention is used in conjunction with a punching machine to realize the punching and forming of the oblate shape of the front part of the processed anti-collision bar product 13 by relying on the power of the punching machine. The molding die includes a molding device, a pressing mechanism, a mandrel and a pushing device. figure 1 Shown is a schematic diagram of the pressing device and the pressing mechanism in working state, and the process of stamping the processed anti-collision bar products; figure 2 It shows a schematic diagram of the pressing device being opened, the pressing assembly 11 lifted with the upper template 12, and the pushing device pushing the material.

[0026] See figure 1 , image 3 , Figure 5 , The profiling device includes an upper template 12, a symmetrically arranged left wedge-shaped pressing block 16-1, a right wedge-shaped pressing block 16-2, a symmetrically arranged left wedge-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com