Blowing-exhausting welding-fume purifying device

A technology for purification equipment, air supply and exhaust, applied in chemical instruments and methods, dispersed particle filtration, membrane filters, etc., can solve the problem that smoke and dust control equipment cannot be realized in large workshops, etc., to reduce equipment volume and equipment resistance, increase equipment. The effect of large ventilation volume and good circulation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

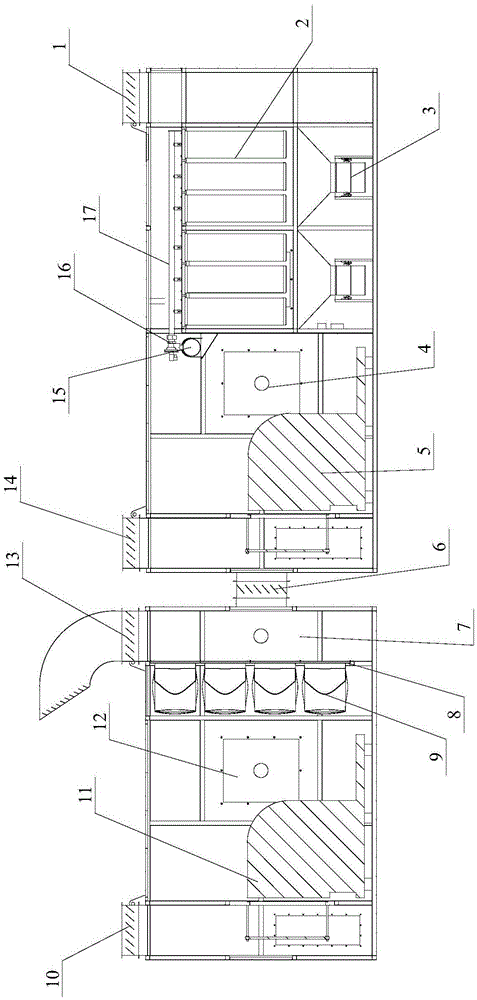

[0018] The invention provides an air supply and exhaust welding fume purification device, which improves the filtering wind speed, is suitable for filtering and purifying large-scale workshops, and has a high degree of automation. The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0019] Such as figure 1 As shown, the air supply and exhaust welding fume purification equipment provided by the present invention includes an exhaust fan unit, a blower unit and a PLC control system. The exhaust fan unit is used to purify the exhaust gas in the workshop, and the air supply unit is used to purify the outdoor air and introduce it into the workshop. When the two cooperate to operate, they are used to further purify the exhaust gas.

[0020] The two sides of the exhaust fan unit are respectively provided with an air inlet 1 and a first ventilator, along the direction of the air flow, a first filter layer and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com