Preparation method of radix cynanchi auriculati lactobacillus-fermented active milk beverage and beverage thereof

A technology of lactic acid bacteria fermentation and Baishouwu, applied in dairy products, Lactobacillus, Streptococcus/Lactococcus, etc., can solve the problems of small added value, pollute the environment, waste resources, etc., and achieve good inhibitory effect and high activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

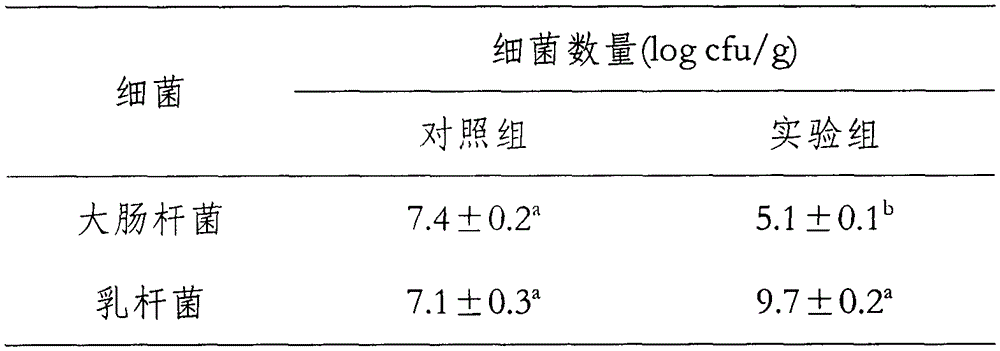

Examples

Embodiment 1

[0020] Baishouwu 5kg was washed to remove impurities, boiled at 100°C for 30min to soften it, added 9 times of drinking water, used crushing equipment at a rotor speed of 1500r / min, a stator-rotor gap of 0.5mm, beating for 10min and then passed through a 100-mesh sieve to obtain All white Shouwu pulp. After sterilization by ultra-high temperature transient treatment for 5s, 0.5% saccharification enzyme with an activity of 20000U / g was added for saccharification, and saccharification was carried out at 70°C for 4h. Then add water, milk, and white sugar for pre-mixing, so that the content of Baishouwu in the slurry reaches 9-11%, the milk content reaches 9-15%, and the sugar content is 5-8%. After high-level homogenization and 135 ℃ ultra-high temperature transient treatment for 5s, the access volume ratio was 4%, and Lactobacillus bulgaricus, Streptococcus thermophilus and Lactobacillus plantarum were compounded in a ratio of 1:1:1 to form a compound lactic acid bacteria starte...

Embodiment 2

[0022] Baishouwu 5kg was washed to remove impurities, boiled at 100°C for 30min to soften it, added 10 times of drinking water, used crushing equipment at a rotor speed of 1800r / min, a stator-rotor gap of 0.8mm, beaten for 15min, and then passed through a 100-mesh sieve, The whole Baishouwu slurry was obtained. After sterilization by ultra-high temperature transient treatment for 5s, 0.4% saccharification enzyme with an activity of 20000U / g was added for saccharification, and saccharification was carried out at 65°C for 6h. Then add water, milk, and white sugar for pre-mixing, so that the content of Baishouwu in the slurry reaches 9-11%, the milk content reaches 9-15%, and the sugar content is 5-8%. After high-grade homogenization and 140 °C ultra-high temperature transient treatment for 5s, the access volume ratio was 5%, and Lactobacillus bulgaricus, Streptococcus thermophilus and Lactobacillus plantarum were compounded in a ratio of 1:1:1 to form a composite lactic acid bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com