Induction Capacitor Generator

A technology of inductive capacitors and generators, applied in the direction of induction generators, etc., can solve the problems of large power consumption of permanent magnet stator, electromagnet stator, etc., achieve high power generation efficiency, long service life, and avoid the effect of consuming a lot of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

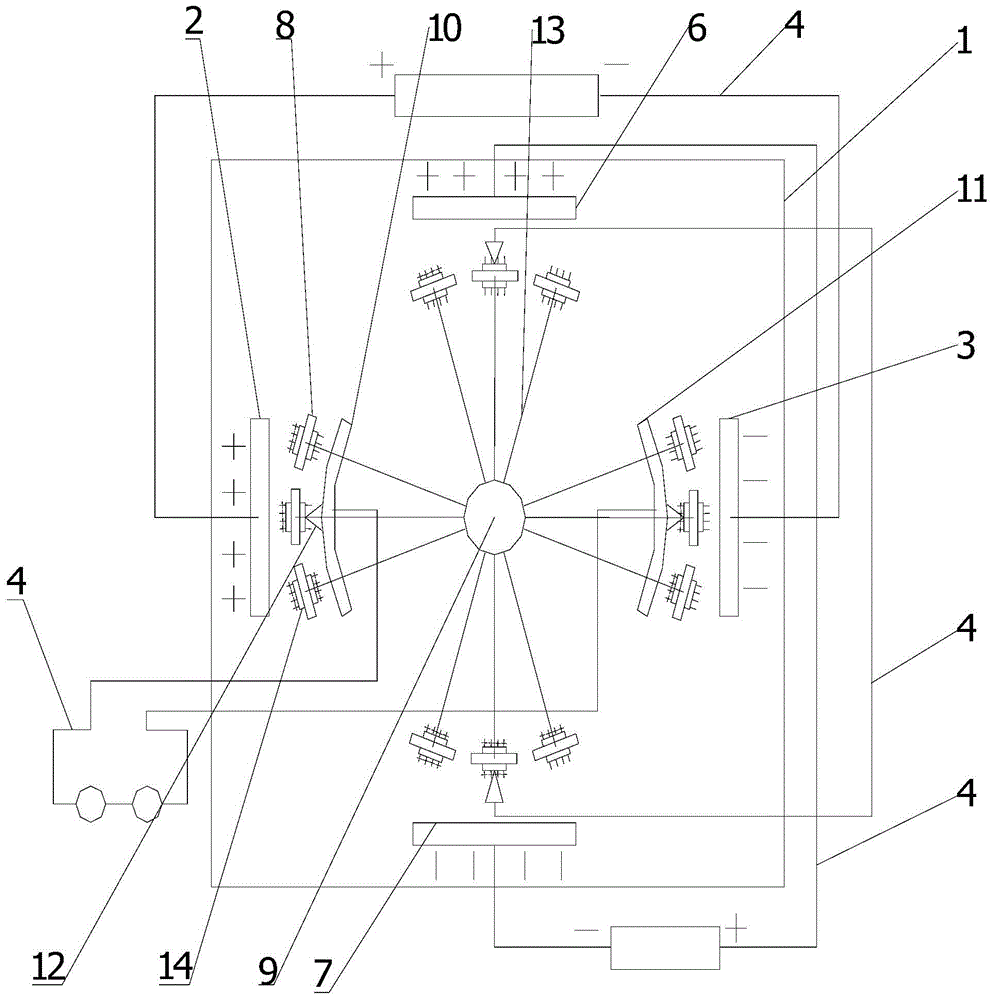

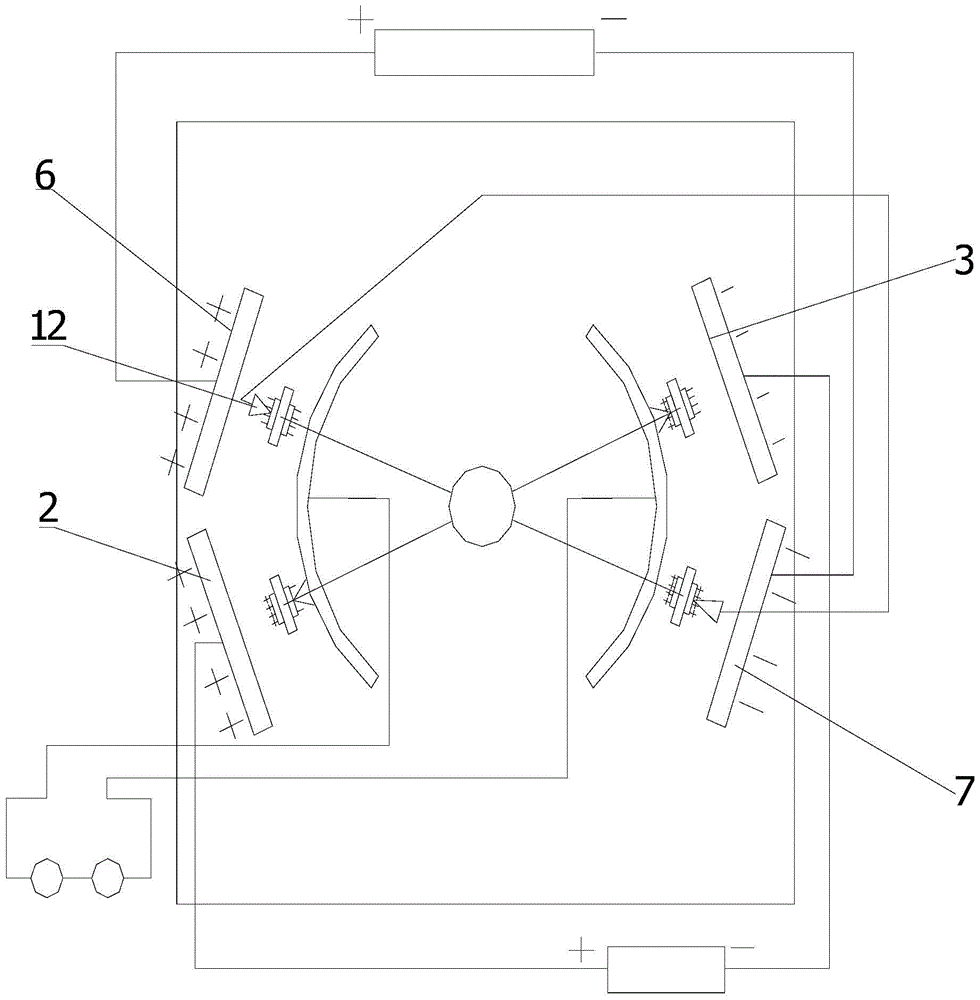

[0041] Such as Figure 1-2 As shown, an induction capacitor generator is provided in this embodiment, the induction capacitor generator includes an insulated base 1, and a first metal plate 2 and a second metal plate are vertically arranged on the base 1 3. The first metal plate 2 and the second metal plate 3 are arranged parallel to each other, the first metal plate 2 is connected to the positive pole of the DC high-voltage power supply 5 through the wire 4, and the second metal plate 3 is connected to the DC power supply through the wire 4 High voltage power supply 5 negative pole;

[0042] The base 1 is also vertically provided with a third metal plate 6 and a fourth metal plate 7, the third metal plate 6 and the fourth metal plate 7 are arranged parallel to each other, and the third metal plate 6 The positive pole of the DC high-voltage power supply 5 is connected through the wire 4, and the fourth metal plate 7 is connected with the negative pole of the DC high-voltage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com