Intelligent rectifier cabinet and temperature control method thereof

A rectifier cabinet, intelligent technology, applied in the direction of conversion of AC power input to DC power output, cooling/ventilation/heating transformation, output power conversion device, etc., can solve the problem of reducing the filtering effect of particle condensation heat exchangers, reducing The service life of surrounding equipment, reducing the service life of equipment and other issues, to achieve the effect of improving cold resistance, ensuring service life and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

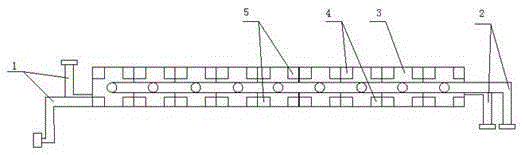

[0021] Such as figure 1 As shown, an intelligent rectifier cabinet and its temperature control method of the present invention include a rectifier cabinet body and a heat exchanger, a plurality of diodes are included in the rectifier cabinet body, and pure water channels are arranged in the diodes; the heat exchanger includes a heat dissipation tube 1. Cooling pipe 2 and a number of parallel heat exchange pipes. The heat exchange pipe is provided with a cooling chamber 3, a heating chamber 5, and a heat dissipation chamber 4. The cooling chamber 3 is connected to the cooling pipe 2, and the heat dissipation pipe 1 is connected to the heat dissipation chamber 4. The heating chamber 5 is respectively provided with an electric heater; the pure water channel is connected to the cooling pipe 2 through a pipeline and a circulating water pump to form a pure water circulation system; the cooling chamber 3 is cross-shaped, and the heating chamber 5 is located at a pair of corners outsid...

specific Embodiment 2

[0024] According to the temperature control system of the intelligent rectifier cabinet and its temperature control method of embodiment 1, it and its temperature control method are:

[0025] Step 1: Start the heat exchanger and rectifier cabinet, PLC controls the flow of pure water at the diode to 0.6L / s; PLC controls the flow of cooling water at the entrance of cooling chamber 3 to 1.2L / s, and the flow of pure water at the entrance of cooling chamber 4 The flow rate is 0.45L / s, and the total power of the electric heater is 0W;

[0026]Step 2: After the heat exchanger, rectifier cabinet, and pure water purification device run stably for 5 minutes, the PLC detects the diode temperature. When the temperature is lower than 21°C, the PLC controls the pure water flow at the diode to 0.55L / s, and the cooling chamber 3 The flow rate of cooling water at the entrance is 1.2L / s, the flow rate of pure water at the entrance of cooling chamber 4 is 0.38L / s, and the total power of the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com